ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Altium, MacroFab Launch New App to Place PCB Orders

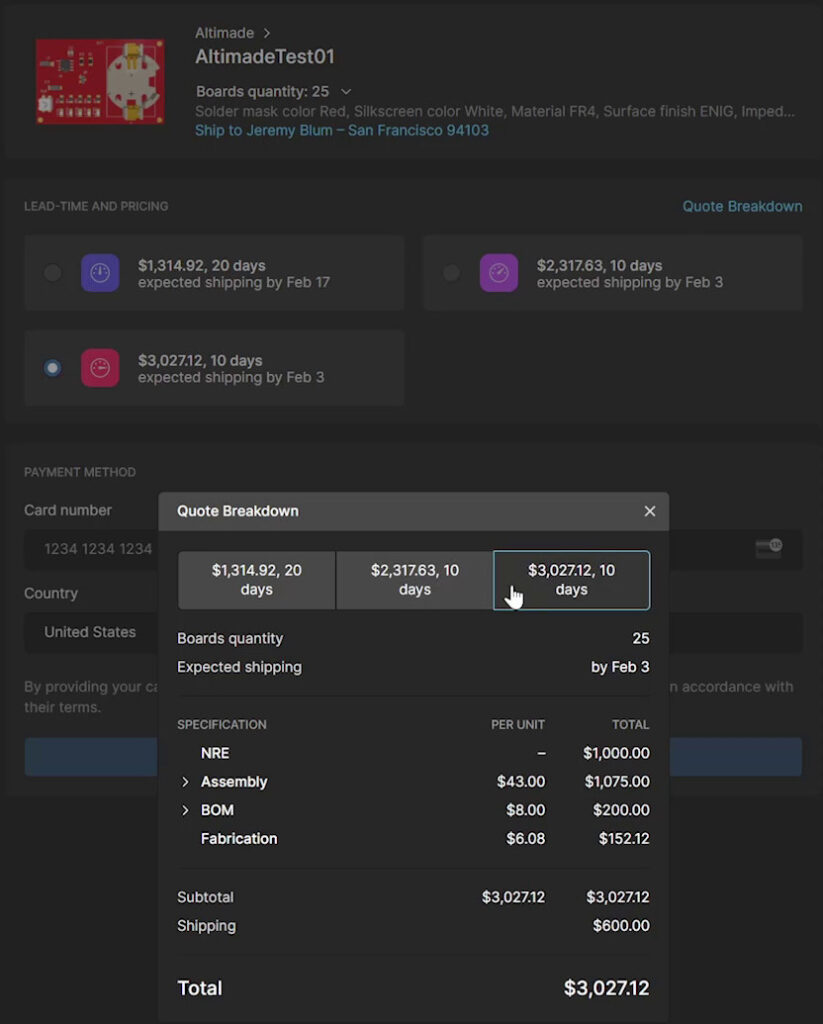

Electronic design automation (EDA) software developer Altium LLC and electronics manufacturer MacroFab, Inc. have made available Altimade, which the two companies described as the electronics industry’s first design with manufacturing application. Particularly, the Altimade application enables customers to request an instant quote and place an order to produce their printed circuit board (PCB) assembly. This is possible even without ever leaving their design environment.

Understandably, the application is available to Altium user community through the Altium 365 cloud platform. Moreover, it is connected directly to MacroFab’s fully digital, elastic manufacturing platform.

Advances Digital Transformation

While the electronics industry produces high-tech products, the process of getting a newly designed PCB is yet to take off. Conventional order process involves communication methods, incompatible tools, and data formats. Furthermore, the process also includes lack of up-to-date supply chain information, which slows the process and leads to costly rework for both design engineers and their manufacturers.

Altimade modernizes and accelerates the prototype manufacturing process by connecting design, manufacturing, and supply chain data and professionals on the Altium 365 cloud platform to provide an easy, convenient user experience.

“By integrating Altium’s cloud platform for PCB design with MacroFab’s modern, digital-first manufacturing platform, Altimade represents a huge step towards the digital transformation of the electronics industry,” said Ted Pawela, Chief Ecosystem Officer of Altium. “We’re no longer designing for manufacturing as a separate activity, but designing with manufacturing in a collaborative environment.”

Adds Value for Customers

Misha Govshteyn, CEO at MacroFab said Altium and MacroFab have modernized PCB design and manufacturing. Hence, they bring them to digital-first, cloud platforms. “Combining them truly redefines the PCB design to the manufacturing process and has the potential to accelerate product development and unlock enormous value for our customers.”

Using Altimade, Altium customers have access to continuously updated component and manufacturing prices and lead times at their fingertips and can place an order to produce their printed circuit boards directly within the design environment. All data for manufacturing comes via the secure, cloud-based Altium 365 platform, without file translations and exports.

MacroFab’s network of manufacturers fulfill the orders in a fraction of the time and effort compared with the traditional process of going from design to manufacture.

Altimade creates, maintains, and displays a complete and continuous digital data trail. Hence, this represents a true “golden record” for every step in the design, procurement, and manufacturing processes of a PCB. Any changes to the original bill of materials or design details automatically update the golden record.

Higher Quality PCBs

Moreover, Altimade helps customers achieve higher quality PCBs by maintaining a digital thread between the design intent and the physical produce. Besides, leaving no room for errors from misinterpretation.

In addition, Altimade helps engineers ensure manufacturability since the Altium Designer software runs design rule checking (DRC) to ensure the design meets MacroFab’s manufacturing specifications.

Supply chain teams use the MacroFab digital platform to build everything from PCB assemblies to fully tested and packaged electronics products. Furthermore, MacroFab aggregates unused capacity at over 75 factories in the United States, Canada, and Mexico to give mid-market companies an alternative to offshoring, where capacity is increasingly constrained and lead times are impacted by supply chain and freight disruptions.

Thus, MacroFab turns its network of factories, logistics centers, and warehouses used in manufacturing into a cloud resource.