ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Digital Thread’s Unique Features Optimize Manufacturing Process

Digital Twin, which represents physical conditions in cyber space for simulation and analyses, has been discussed for quite some time. Recently, a new concept called Digital Thread has been attracting attention. Digital Thread combines the engineering chain and the supply chain to optimize the manufacturing (monodzukuri) process.

In this article, Nomura Research Institute describes the emergence of Digital Thread.

What is Digital Thread?

Digital Twin has been applied for multiple applications: simulate prototyping and tests in a virtual space in the production design stage, virtualize the manufacturing process and simulate the manufacturing line and visualize the operational conditions based on the sensing data from shop floors. However, those efforts have been implemented in each process, keeping the engineering chain (upstream) and the supply chain (downstream) optimized separately.

For that reason, the current challenge is to optimize the whole engineering and manufacturing process by linking the upstream and downstream. In the upstream process, it is difficult to take into consideration the actual costs data from procurement when designing products. In the same way, it is difficult to immediately reflect design changes to the production process (downstream process).

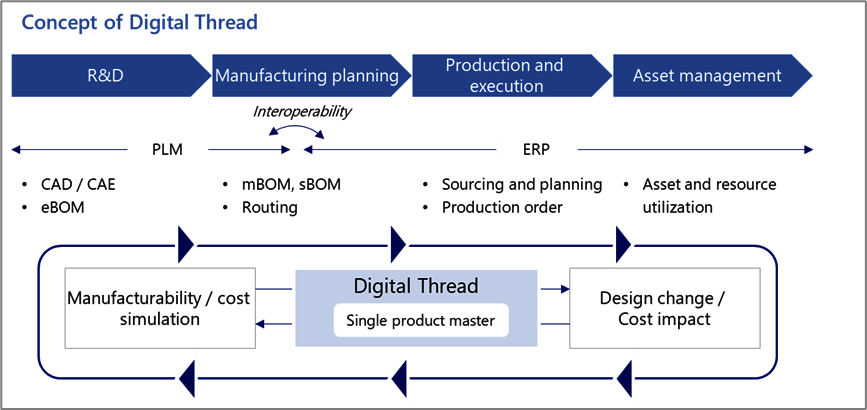

Given those challenges, Digital Thread promotes data linkage between the system in the upstream (data on product lifecycle management (PLM): engineering bill of materials (eBOM) and computer-aided design (CAD), etc.) and the system in the downstream (data on enterprise resource planning (ERP): manufacturing and procurement costs) (Fig. 1).

Through linkage between the upstream and downstream, in the new product planning and design process in the upstream process, it is possible to improve the accuracy of cost estimation for new product design by using actual data on procurement and manufacturing from the ERP side. Automation of the process also becomes possible and could be beneficial as cost calculation was previously performed based on assumption and manual calculation.

In addition, shop floors can smoothly reflect the design changes required from the engineering side. As a result, the lead time of product development process can be expedited.

Use Cases of Digital Thread

Digital Thread is still in the emerging stage in terms of the realization of its concept at both the vendor and user sides. Nonetheless, there are already some use cases. One example is the improvement of the cost simulation accuracy in the early product development phase.

In the process to develop new products, the more you go in the downstream process, the more difficult it would become to change design, while the magnitude of the cost impact would become smaller in the downstream processes. For that reason, it is important to conduct flexible cost value engineering in the upstream processes.

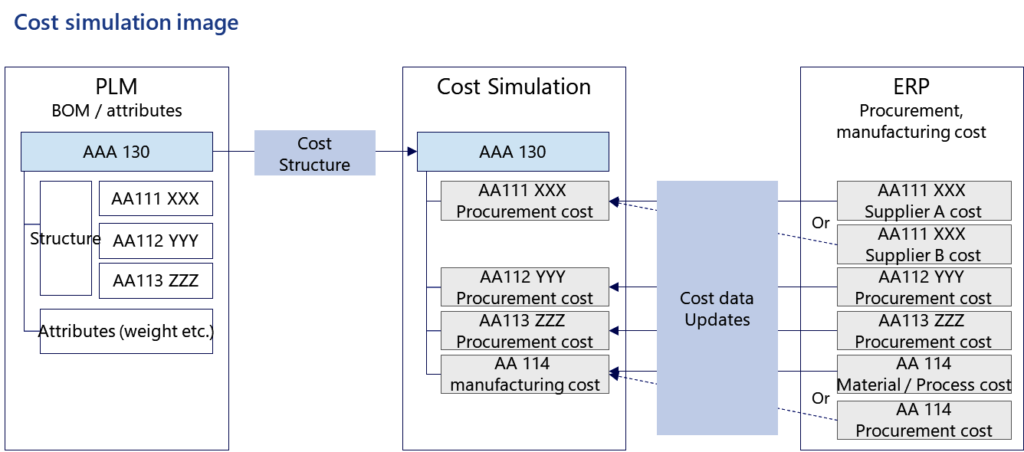

The below describes an example of cost simulation applying Digital Thread to realize accurate and efficient cost management in the new product development process.

Cost simulation is possible by connecting data on component composition of products possessed at the PLM side and procurement cost data of components possessed at the ERP side. Fig. 2 shows data from the PLM side. It shows the decomposed components structure of products designed to be the target of cost simulation using master numbers (AA111~) as the base. Inputting the decomposed component units and the procurement results and actual costs at the ERP side associated with the master numbers of the same components enables the cost simulation of the designed products by reflecting historical and actual procurement prices at the ERP side.

Furthermore, when there are cost data of multiple vendors associated with the identical components and master numbers, and when own company’s production costs and procurement costs from external vendors are stored associated with master numbers, it is possible to conduct cost impact simulation by changing vendors or changing between internal manufacturing and procurement. Thus, it is possible to conduct value engineering by taking into consideration more accurate costs at the design stage.

Above is just one application example of the Digital Thread. The linkage between upstream and downstream will likely become deeper in such a way seen in this example.

Going forward, at the upstream side, input from the downstream side will enable early consideration of manufacturing feasibility including data (such as those on manufacturing equipment) that contribute to the consideration of bottlenecks in manufacturing, in addition to costs.

Meanwhile, at the downstream side, PLM data, such as design changes in the upstream side will be directly reflected in instructions in the manufacturing process. Such application cases will likely emerge as feasible cases.

About This Article:

The author is Takuro Motohashi, Senior Associate, Mobility Service Group, Global Manufacturing Industry, Consulting Department, Nomura Research Institute, Ltd.