ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi Electric Preps up 3D Digital Twin Simulator

Mitsubishi Electric Corporation is set to release on April 28 the MELSOFT Gemini 3D simulator, which will expedite the design and construction of production facilities. It will use digital space to simulate and verify envisioned production operations in a three-dimensional (3D) environment.

By connecting to a variety of software and factory devices, MELSOFT Gemini will visualize, simulate and help streamline manufacturing work processes, ranging from design of production facilities to operation and maintenance.

Rising Need for Digital Technologies

The recent pandemic has caused restrictions on human mobility and face-to-face communication. Thus, it has made it difficult for manufacturers to install and maintain production facilities. Meanwhile, the manufacturing sector is seeing growing demand for the digital transformation of factories.

These industry trends have brought the spotlight on to the use of digital space for solving various issues on production sites. MELSOFT Gemini can help solve such issues and streamline processes by using digital space to simulate the operation of production facilities before they are installed and operated for real.

Going forward, Mitsubishi Electric will continue to provide value to customers throughout their manufacturing lifecycle with digital technologies.

Product Features

3D digitalization of production facilities for easy verification

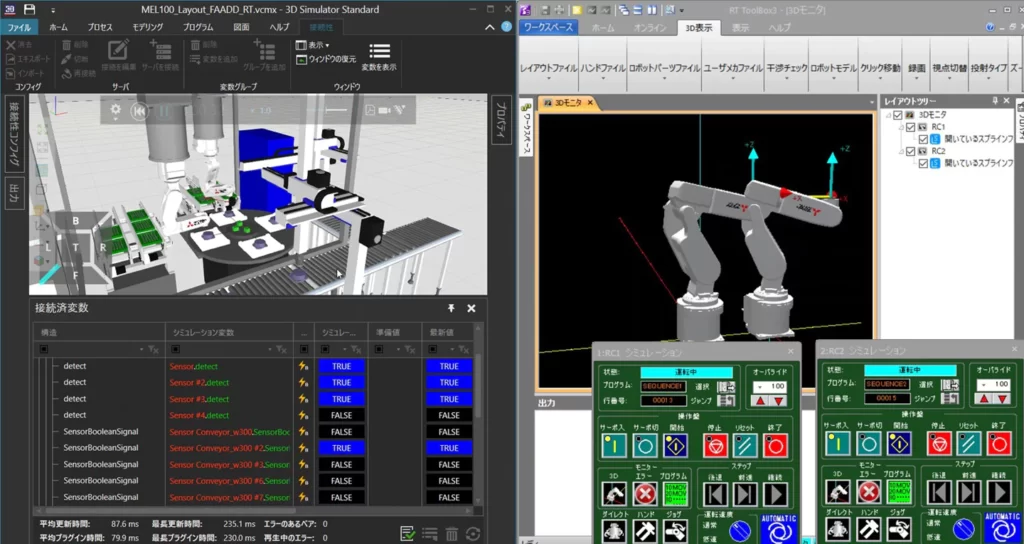

MELSOFT Gemini simulates the operation and control of production lines and equipment using a PC-based 3D digital space. This way, digital verification can be made to support the fast and simplified launch of actual equipment and lines later on.

MELSOFT Gemini connects to MELSOFT simulators, which are available separately as part of the “MELSOFT iQ Works” software package. This simulates the control of devices, such as programmable logic controllers (PLCs) and motion controllers (Servos). During the verification process, facility engineers can check the status of the planned production facility through the PLC sequence program. This way, displays of operational waveforms and/or video data when an error is found can be reviewed.

MELSOFT Gemini directly connects to the MELSOFT simulator and factory devices without having to go through an OPC server. This process enables 3D data to be updated in digital spaces approximately 12 times faster than OPC environments (Mitsubishi Electric as of March 29, 2022). Moreover, detailed checks for possible operational interference can reduce the need to rework processes, and help to improve quality.

In the operation and maintenance phases, the causes of abnormal occurrences in the production line can be determined quickly using visual data. These are then provided to line operators through MELSOFT Gemini.

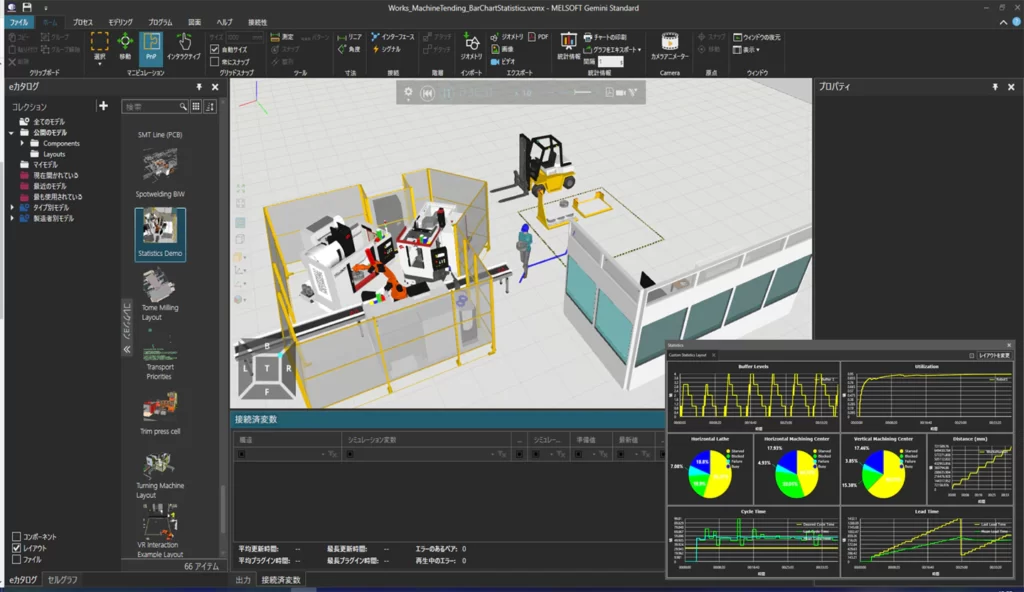

Diverse hardware menu and graphical and statistical functionality for extensive analysis

The supported hardware menu (e-catalog) offers hardware selection from approximately 2,500 types of diverse production equipment. Among them include robots, conveyors, processing machines and more. These can be combined in a simulated 3D production facility via easy drag & drop operation. Also, various parameters can be easily set on the 3D screen to adjust the layout of the production line.

Line, area, bar, and circle graphs can be used to visualize and analyze simulation data on different operating rates of production; thereby supporting the design of extra-efficient production lines. Moreover, equipment operating status, production task duration, worker wait time, and others can be statistically quantified. They can be displayed with graphs to identify different production yields and operating rates. This feature enables lines to be designed and upgraded with efficiency.