ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Molex Expands Industrial Automation Solutions to Speed up Industry 4.0

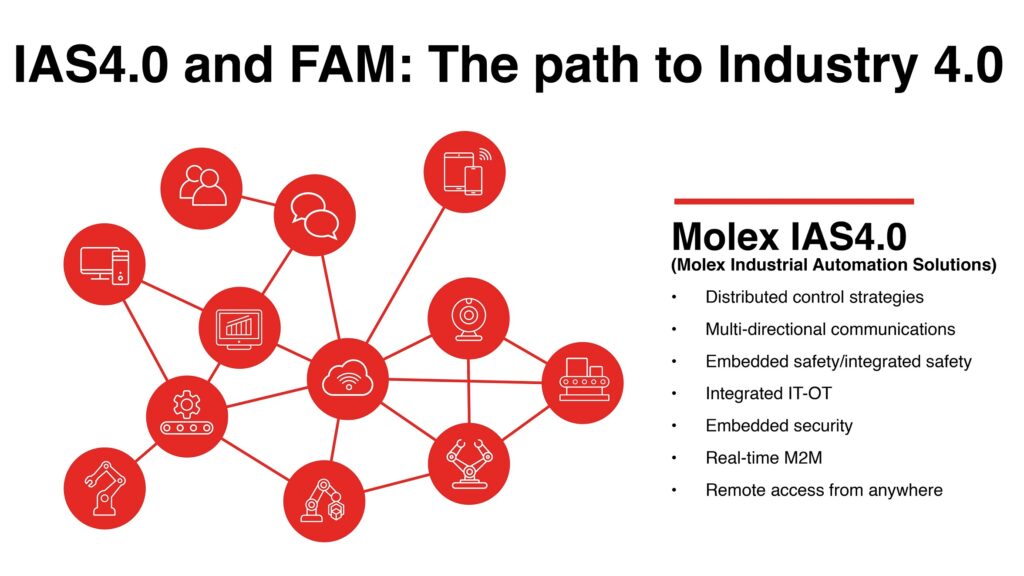

Coupled by efforts to sustain developments that drive advances across its Industry 4.0 and digital manufacturing initiatives, Molex now introduces Flexible Automation Modules (FAMs). These efforts further extend its Industrial Automation Solutions (IAS4.0) by empowering supply chain stakeholders to build software-defined machines, robots and production lines that meet escalating demands for connected, secure, scalable and efficient operations.

Compared with traditional manufacturing with limited flexibility, John Newkirk, VP and GM of Industrial Solutions at Molex, said “Our legacy in industrial automation, coupled with Molex’s long-standing relationships across the factory automation ecosystem, is fueling the development of open, modular IAS4.0 and FAM solutions that significantly improve efficiency while reducing complexity, cost and time to market.”

FAM Functionality Delivers Unprecedented Flexibility

As the core building blocks of IAS4.0, FAMs offer highly configurable and customizable connectivity, distributed control, and Industrial Internet of Things (IIoT) apps to speed the development of flexible, modular and connected manufacturing machines. Pre-certified and custom FAM functionality encompasses distributed control, embedded safety and security, multi-directional communications, provisioning and device management, as well as remote configuration and programming services.

Critical manufacturing data can be collected and shared seamlessly—from sensors or complex devices, as well as between devices, machine-to-machine (M2M) or to edge devices, and the cloud. Feeding this data to artificial intelligence (AI) and analytics solutions will help expedite the delivery of actionable operational insights. Additionally, real-time data capture can help pinpoint potential issues to elevate predictive maintenance and decrease downtime while seamless integration with critical business systems and services supports effective decision making.

The opportunity to eliminate manual steps and reduce hardware dependency leads to lower total cost of ownership, improved margins, and greater agility in meeting emerging digital manufacturing demands. The use of pre-certified and custom apps as well as libraries also help equipment manufacturers shorten design cycles by speeding development of the control requirements of individual machines

Increasing Automation Improves Outcomes

Molex IAS4.0 and FAM are ideally suited to transform industrial automation supply chains in the automotive, food & beverage, and material handling industries. By reducing rigid hardware dependencies, manufacturers can reconfigure production lines to support the manufacturing of custom products.

Future applications of Molex’s advanced industrial automation solutions include the deployment of ruggedized IP67 devices to simplify wiring while improving reusability and portability; the deployment of advanced sensors, such as motion safety, required for collaborative robots; and zero-touch provisioning and asset management services that update devices, machines and systems automatically or on demand.