ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Joint Research Yields Soft Material for Solid Battery

Kyoto University, Tottori University, and Sumitomo Chemical Co., Ltd. have successfully developed a new soft material for solid-type batteries. Specifically, the material makes it possible to create, without applying pressure, high-capacity solid-type batteries that operate stably.

The development of soft solid electrolytes is one of the major challenges toward the commercialization of solid-type batteries, which are attracting attention as the next-generation secondary battery. The collaborators in this development have succeeded working on material development based on an innovative new concept.

Solid-type Batteries

While lithium-ion secondary batteries use liquid electrolytes, solid-type batteries use solid electrolytes. They have attracted attention in recent years as they may solve the challenges faced by commercially available secondary batteries in terms of capacity, charge-discharge time, and safety. The inorganic sulfides-derived solid electrolytes in solid batteries are hard and inflexible. However, a major issue remains in improving the interface contact between solid electrolytes and electrodes to ensure good battery operation.

Generally, pressure is applied to the battery cell to establish the interface contact necessary for activating the battery. However, this requires components to be added for pressurization, leading to increased battery weight and cost. Meanwhile, weak contact could result in poor battery performance.

Soft Solid-type Batteries

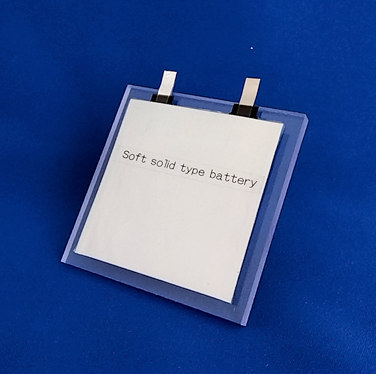

To overcome this challenge, Kyoto University, Tottori University, and Sumitomo Chemical launched their industry-academia joint research program in 2020. They set out to demonstrate the operation of soft solid-type batteries using flexible solid electrolytes. These electrolytes established interface contact with electrodes without applying pressure.

As a result of repeated trial and error, researchers from the group have successfully developed a solid-type battery with a capacity of approximately 230Wh/kg. They used a non-pressurized process employing a new material. This achievement is expected to contribute to accelerating the commercialization of solid-type batteries with a high level of safety as the components for pressurization can be eliminated, leading to significant reductions in battery weight and cost.

Solid-type batteries are being developed at an accelerated pace for their high capacity and long life. They are applied as small-sized batteries for consumer electronic devices, such as smartphones and wearable devices, as well as medical equipment. Furthermore, they can be employed to a wider range of fields, including the next-generation battery for EVs. EV batteries are required to have high-energy density and high-output characteristics from the viewpoint of cruising range and recharging time.

Reinventing Next-Generation Batteries

Kyoto University strives to lead the world’s energy storage technology development from the basic research level, setting sights on the next generation. It effectively utilizes industry-academia joint research programs. Through this effort, the university will take on the challenge of delivering world-first research results and bringing about new innovations while developing human resources to lead in materials technology development.

Tottori University aims to promote advanced research to solve global and societal issues under its basic philosophy of “fusion of knowledge and practice.” Inheriting the honorable traditions of its predecessors, including Tottori Advanced Agricultural College and Yonago Medical College, the university will continue to engage in education, research, and social contribution, transcending the boundaries of individual disciplines through efforts such as the establishment of the Graduate School of Science for the Creation of a Sustainable Society and collaboration between medicine and engineering.

Sumitomo Chemical has defined environment, food security, healthcare, and ICT as its four priority areas for next-generation business development in its new Corporate Business Plan launched in FY2022. The company is building an innovation ecosystem in collaboration with academia and start-ups. In addition, it is working to reorganize and further strengthen its R&D operations and striving to create new high-functional materials that may provide new solutions for a wide range of industries, while also accelerating new business development.