ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Epson’s Proven Technology Makes Versatile 3D Printer

Seiko Epson Corporation has developed an industrial 3D printer that can use commonly available third-party materials to produce accurate industrial parts of various sizes and functions. Consequently, 3D printers with these features will have a far wider range of applications. These applications include production of parts for final products. In addition, this will enable users to mass-customize their goods in support of small-batch production.

3D printers can be used to fabricate a wide variety of goods in small quantities in a short period of time. Manufacturers have responded to this by accelerating the development of 3D printers for the industrial market. In fact, many see this market to expand rapidly in the future.

Nonetheless, conventional industrial 3D printers require the use of special modeling materials. Moreover, they do not suit the production of objects that offer both strength and accuracy, hence limiting their use in industrial parts for final products.

Innovates Manufacturing Processes

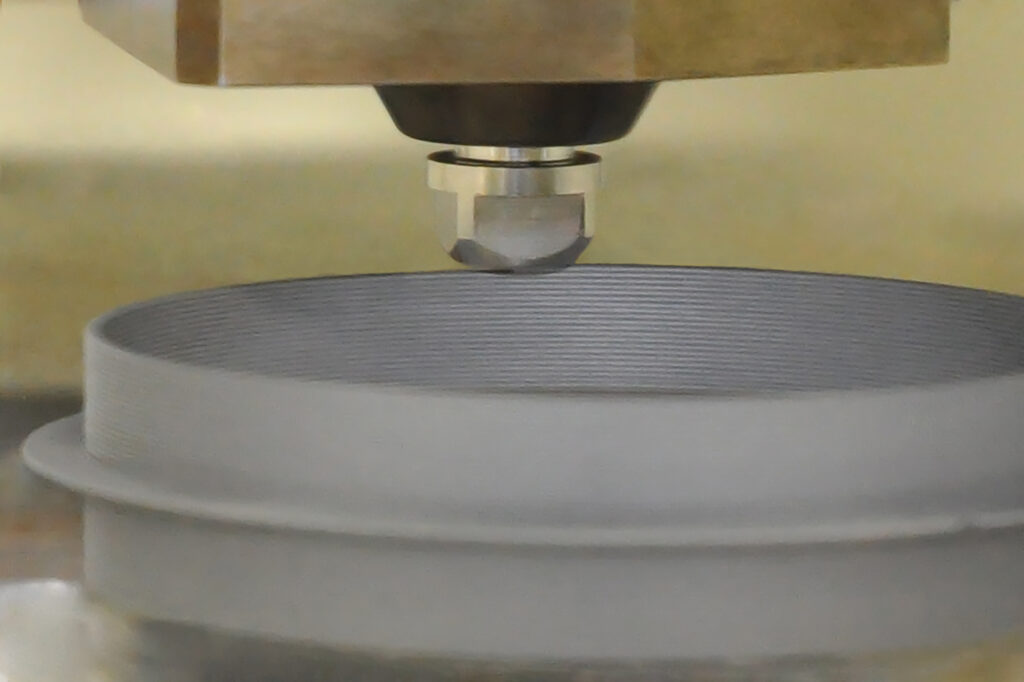

Epson’s newly developed 3D printer employs a unique material extrusion method. The use of a flat screw, or an inline screw with flattened configuration, makes this possible. Specifically, Epson’s precision injection molding machines also have this same method.

In addition, the extrusion method enables the printer suitable for use with a variety of common third-party materials, such as resin or metal pellets. These are available at lower cost compared with other materials, environmentally friendly, and can provide good high heat resistance.

In addition, regulating the pressure within the head and by regulating the action of a valve in concert with the modeling speed can control the amount of material injected. To obtain the required strength, controlling the temperature at the surface of a piece being printed is also important.

Best of all, Epson employs a unique mechanism to precisely control this temperature and achieve both strength and accuracy. This 3D printer can manufacture strong and accurate objects with commonly available material. Hence, this will facilitate printer use in the production of industrial parts for final products. In addition, it also suits mass customization, as it can produce small batches of parts tailored to customers’ needs with higher quality and shorter lead times. Most importantly, it comes at a fraction of the cost of traditional manufacturing processes.

Epson is aiming to commercialize the printer after first making needed refinements while utilizing it internally to volume-produce certain parts for commercial and industrial equipment.

In addition to industrial 3D printers, Epson seeks to innovate manufacturing by co-creating flexible, high-throughput production systems that reduce environmental impacts.