ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Azbil Starts New High-Precision Controller

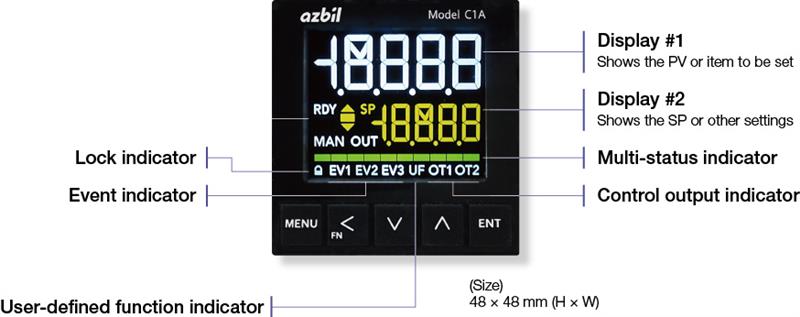

Azbil Corporation has started the sales of the model C1A single loop controller. Particularly, it features high accuracy and fast response and reduces the burden on personnel, from C1A installation through maintenance.

Despite its compact 48×48 mm front panel size, the C1A achieves a high accuracy of ±0.1 percent of the reading and high-speed response with a sampling cycle of 25msec. In addition, they come equipped with various labor-saving functions for manufacturing sites.

Single loop controllers compare signals from sensors with the set values, execute PID control*1 according to the amount of deviation. At the same time, output control signals to actuators for keeping the control target (temperature, pressure, flow rate, etc.) at the correct level. They are essential devices for efficient operation at factories and plants. Furthermore, Azbil provides single loop controllers with a variety of functions that are required for applications in the factory automation market.

High Accuracy, High Speed Response

As typified by semiconductor manufacturing facilities, compact and high-performance equipment is necessary for maximizing productivity in limited factory space. For devices like single loop controllers, built into other equipment, there is a growing demand for smaller size and higher performance.

In addition, it is important while equipment is running to reduce downtime by maintaining a constant understanding of the state of processes in order to prevent problems from occurring. Also, to cope with problems like a decrease in skilled workers and labor shortages, the manufacturing industry has begun to use more intuitive and simpler methods of PID adjustment rather than methods that rely on experienced workers.

Despite its compact space-saving size, the C1A achieves high accuracy and high-speed response. Its multi-status indicator allows onsite personnel to grasp the status of the controlled process immediately. Also, communication with a programmable logic controller (PLC) can be set up easily without the need for special programs. This makes it easy to create a system for remote process monitoring, for example, using a host system, touch panels, and other external devices.

Monitoring Resistance of Heater

One of the main applications of controllers is controlling temperature using electric heaters, which deteriorate and have a limited lifecycle. Hence, an effective method of diagnosing deterioration is to monitor the resistance of the heater.

The C1A calculates the voltage, current, and resistance of the heater using voltage transformer (VT) and current transformer (CT) inputs. Monitoring of these values is possible on the front panel of the C1A.

By monitoring the resistance along with the controlled temperature, it will be easy to understand the condition of a heater and prevention of unexpected heater burnout is possible.

In addition, the Smart Loader Package for the product includes a PID simulator based on proprietary Azbil simulation technology as a standard feature. The PID simulator uses operating data to create mathematical models that reproduce characteristics of the object of control, allowing the user to simulate PID control on the PC and reduce adjustment time.

*1 This type of feedback control operates on the basis of sensor measurements in order to keep the temperature, pressure, and other variables inside of manufacturing or processing equipment at the desired levels. PID refers to proportional, integral, and derivative action.