ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

THK Beefs up OMNIedge with Tool Monitoring AI Solution

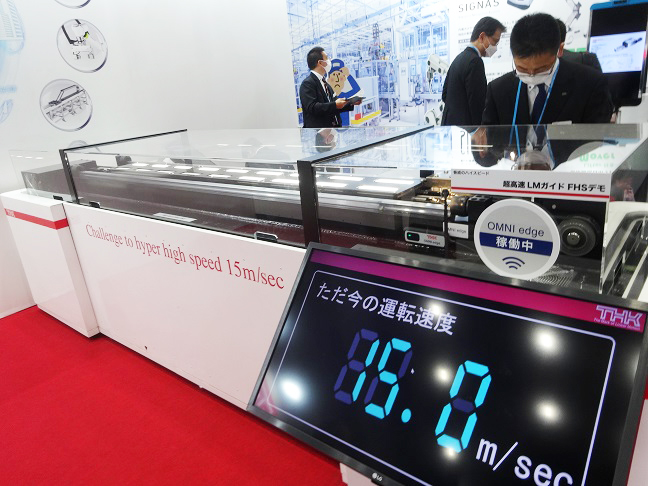

THK Co., Ltd. expands its offering of OMNIedge internet of things (IoT) service for the manufacturing industry. Specifically, it starts to provide a tool monitoring artificial intelligence (AI) solution.

OMNIedge IoT Solution

THK launched OMNIedge IoT service in Jan. 2020. Through OMNIedge, THK provides a solution that reduces losses occurring in manufacturing floors. Also, it contributes to improvement of overall equipment efficiency (OEE).

Sensors are attached to machine element components of linear motion (LM) guides and ball screws. Collected data are quantified by the company’s original algorithm for analysis to visualize the status of components, thereby achieving predictive failure detection. Installing a communication function enables remote monitoring is enabled. OMNIedge is a package service to provide a set of hardware, such as sensors, and communication equipment, including communication cost. The IoT package is simple, safe, and available at reasonable price.

THK started the service for linear motion components of LM guides, ball screws, and actuators. Then, the company has expanded the target of the service to encompass rotation components, such as motors and pumps for process automation and utility equipment. Thus, it has deployed a predictive component failure detection AI solution.

Tool Monitoring AI Solution

The new tool monitoring AI solution eliminates the need for cumbersome threshold settings. Moreover, it solve challenges of cutting tools for machine tools.

There are many requirements for cutting tools from manufacturing floors. These include the “need to reduce costs of tools, while optimizing life management” and the “need to prevent the occurrence of defects due to breakage and chipping and loss due to repair.” Previously, the general rule was to replace tools at an early stage based on the number of works processed. Consequently, they do not cause defects. However, because tools were replaced based on safety coefficient even though there was no abnormality, costs relatively increased.

The tool monitoring AI solution can be retrofitted. Thus, it enables easy introduction to machine tools already operating in the manufacturing site, as well as to those made by different manufacturers. Particularly, it can detect breakage and chipping of cutting tools. Further, it can also monitor and detect abrasion degree. Eventually, it enables businesses that operate machining in mass quantities to optimize tool life and reduce tool replacement costs and losses for repairing of defects. Thus, they can expect high cost-effectiveness.

Data collected from sensors are automatically analyzed by AI, which detects abnormalities. Hence, repeated use improves accuracy.

Simply clamping a current transformer (CT) (current sensor) to the motor cable completes the installation. Connection to computerized numerical control (CNC) is not necessary and hence, the tool monitoring AI solution is free from the restrictions of model year and manufacturer of machine tools. It does not require complicated settings using setting tools. Upon installation, it can monitor and obtain data. AI automatically analyzes data and detects abnormalities based on the data. Hence, accuracy improves with repeated use.

Global Compatibility of OMNIedge

OMNIedge can be connected to FANUC CORPORATION’s “FIELD system” open platform, “Edgecross” and “MindSphere” by Siemens, and other industrial platforms.

THK has been expanding the service to China, the United States, Thailand, Indonesia, Taiwan, and Singapore, supporting global SIM. Also, it can be used using overseas communication networks. Through compatibility with global SIM, OMNIedge achieves visualization of machine element components operating in overseas plants from Japan.