ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

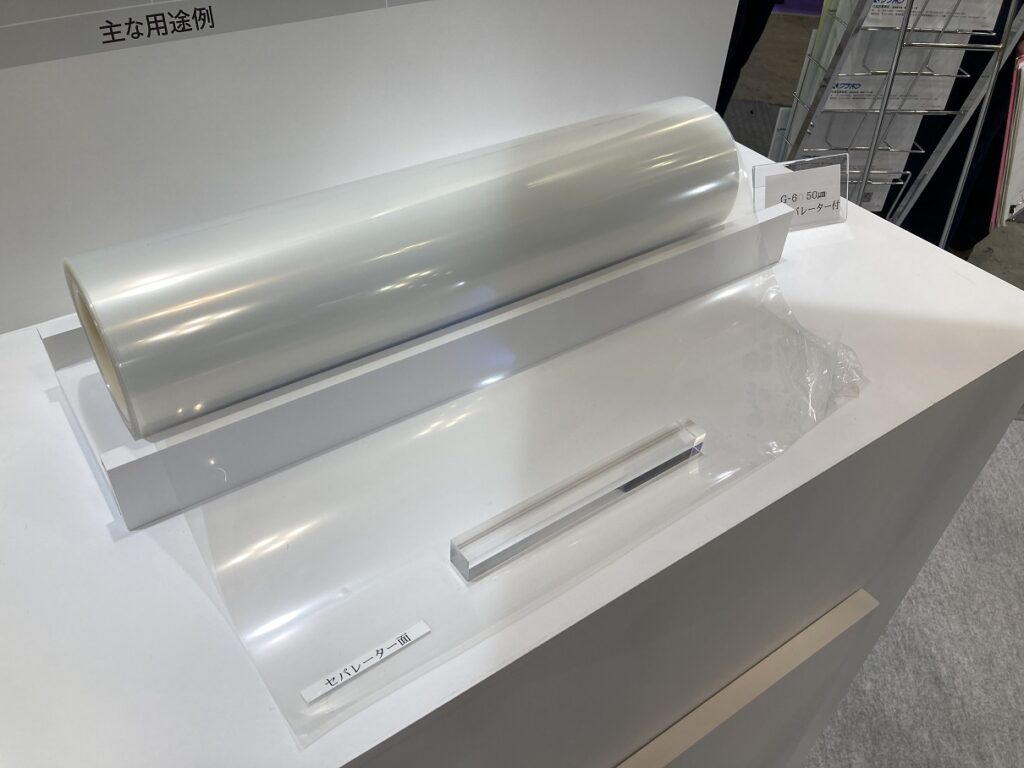

Kurabo Widens Array of Solutions for Films

Japanese manufacturer Kurabo Industries Ltd. has been deploying a wide range of solutions for films. Its chemical product business handles high-functional films.

KuranBeter Adhesive Film

KuranBeter, a hot-melt adhesive film, also works as an adhesive. It is heat-melted and bonded, and adheres as it cools. The adhesive film is used to laminate polyester films of traffic-related IC cards.

Specifically, the low-temperature-adhesion grade films adhere even at temperatures of around 90℃. Thus, they prevent deformation of mating materials resulting from overheating. This grade of film applies to adhering flat cables.

For applications that require heat resistance, KUROBO recommends the development grade. For example, it is used for the car interior, which becomes extremely hot in direct sunlight. Polyester-based hot-melt films are used for adhering decorative films that provide wood grain patterns and other patterns on instrument panels and doors.

Olefin-based hot-melt films are chemical-resistant films. Kurabo intends to expand their applications to electrode terminals of lithium ion batteries.

Meanwhile, Geo-Flow biomass films are environment-friendly materials. Kurabo promotes it to reduce usage quantity of petroleum-derived resin.

Transparent-grade biomass films are made of 100 percent biomass with no petroleum content. Meanwhile, biodegradable UP-grade biomass films contain 15 percent petroleum-derived components. They contain an additive, which accelerates speed of biodegradation process.

Flexible-grade biomass films are excellent in tensile elongation and are easy to form. Acetylcellulose-based products are transparent and can be used for see-through blister containers.

Natural product-derived-grade biomass films contain minerals to reduce usage quantity of plastics. They can be formed for use as lids of coffee containers.

Oidys heat-resistant polystyrene films deliver heat resistance and mold releasability. They feature low-dielectric constant and can be used for high-frequency substrates.

EXPEEK bi-axially oriented polyetheretherketone (PEEK) films feature high heat resistance to 300℃. They excel in transparency, surface smoothness, and low dielectric characteristics compared with polyimide. Another differentiating property is that they can be peeled by ultraviolet transmission through combination with an adhesive layer. EXPEEK films are demanded for use as industrial tapes in semiconductor manufacturing.

For its customers, Kurabo proposes the appropriate films in accordance with applications from among its diverse lineups.

Thickness Measurement of Adhesives

Kurabo’s Environmental Mechatronics Division provides measuring instruments to measure the thickness of adhesives to laminate films.

Specifically, infrared absorption type film thickness meter uses differences in the absorption region of infrared rays, which differs from material to material. It measures thicknesses of adhesives and coat layers without being affected by the thickness fluctuations of film substrates.

Meanwhile, soft packaging materials are used for foodstuffs and livingwares. They are created by laminating multiple films featuring functions, like hardly permeating oxygen and difficult to tear. Insufficient adhesion inhibits these functions and affects the safety of foodstuffs. Hence, to control the application amount of adhesives, an infrared absorption type film thickness meter is needed.

The film thickness meter also measures the thickness of fluids, such as water-based coatings. Moreover, it is also applied in thickness measurement of optical films, and thickness measurement of organic and inorganic coatings on sheet steels. Also, it measures coat layers from 0.1μm.

Kurabo gets multiple inquiries from the overseas market, such as countries in Europe. Specifically, inquiries zero in on products for measurement of the coat layer of films used for separators of lithium ion batteries.

The company meets various measurement needs by offering the film thickness meter with wavelengths corresponding to layers and components to be measured.