ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Emerson’s Unique Solutions Pitch Greener Manufacturing

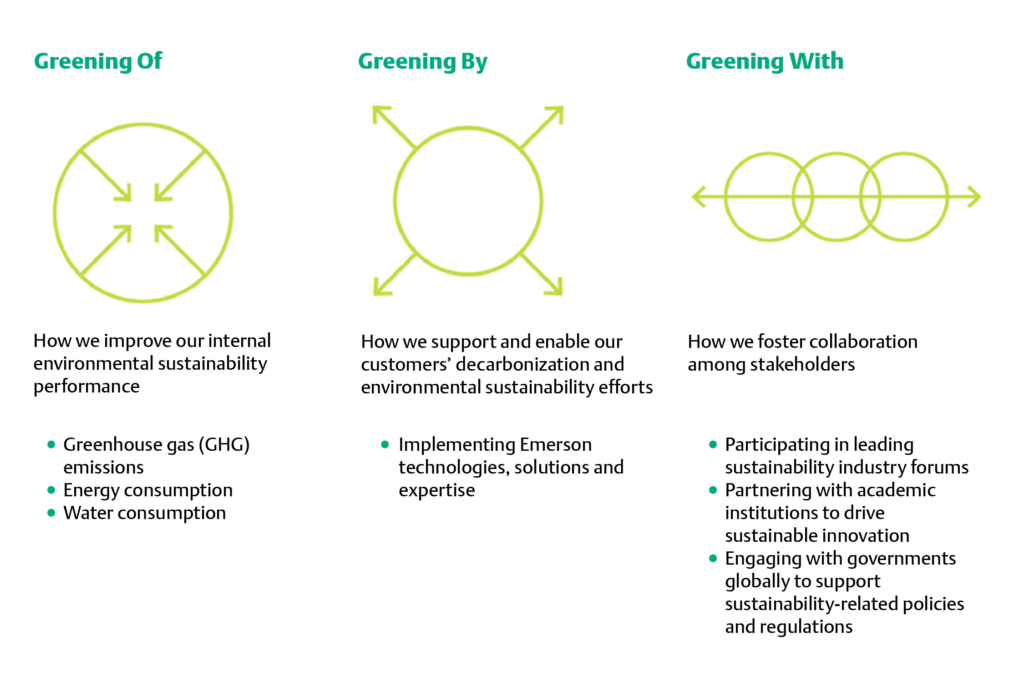

Emerson Electric Co. has reinforced its role in enabling a more environmentally sustainable world. Particularly, the company further enhanced its environmental sustainability strategy through its Greening Of, Greening By, Greening With framework, which it introduced in 2020.

In an interview with AEI, Dr. Amit Paithankar,Vice President, Advanced Design Center at Emerson, said the framework summarizes how they are evolving to make the world more sustainable. To illustrate, the framework defines the efforts of the company in improving its internal sustainability program. In addition, it also focuses how to support their customers’ decarbonization efforts and extend such with the various other stakeholders.

“At Emerson, we are serious about focusing our efforts and purpose around environmental sustainability. Besides, driving progress within our facilities and helping our customers achieve their ESG objectives as part of our global environmental sustainability strategy,” said Paithankar. He is also Emerson’s concurrent Managing Director for South Asia.

Optimize Operation Efficiency, Sustainability

Advancements in manufacturing technologies have enabled industrial manufacturers to embrace digital technologies. As a matter of fact, these technologies have also enabled data-driven insights to support sustainability goals.

Paithankar said Emerson’s solutions have been driving manufacturers not only to optimize operational efficiencies of their respective plants and facilities but also achieve sustainability benefits.

For example, Paithankar cited the compressed air driving mechanical motion in manufacturing operations. Specifically, he noted the cost to compress the air for pneumatic power. Any leakages not only decrease operational performance but also waste energy and increase emissions.

Emerson technologies and solutions, such as smart pneumatics and software monitoring and notification, can help detect leakages, save energy, and reduce emissions. In addition, these technologies also contribute in reducing downtime, enable faster cycle times, and increase overall productivity.

Another example Paithankar cited are technologies that tackle serious food waste problems, particularly in Asia. Incidentally, Emerson’s Cold Chain solutions can accurately track shipments and share the data across its logistics network with the ability to monitor information and control refrigeration equipment in real-time. It allows for better control of the cold chain, increasing operational efficiencies, minimizing food wastage, and saving costs.

“Emerson solutions help manufacturers achieve top quartile business performance through the industry’s broadest portfolio of technologies to measure, control, optimize and power their operations,” said Paithankar. Furthermore, he noted “more manufacturers are recognizing the sustainability benefits of these technologies”.

In addition, Paithankar said Emerson’s software offerings are also pivotal across these environmental sustainability efforts. For one, the Plantweb™ Optics Analytics software makes use of artificial intelligence and machine learning. Accordingly, it enables reduction of energy use, GHG emissions and material waste, while optimizing production for industrial manufacturers. Moreover, the company also introduced augmented reality (AR) to Plantweb™ Optics, enabling workers enhanced access to critical information. Thus, empowering remote collaboration to maintain operations and prevent downtime.

From Within and Outside

It is important for Emerson’s environmental sustainability framework to stand on solid ground. For that reason, the company needs to enhance its own environmental performance across its global manufacturing network. That being the case, the company started the greening framework within itself.

In 2020 alone, Paithankar said the company already reported a 10 percent decrease in CO2 emissions. Particularly, it cut down by 11 percent its global electricity usage and lowered by 18.15 percent its global water consumption. These accomplishments cover the company’s 185 manufacturing facilities around the world, 45 of which are in Asia, as well as in 548 non-manufacturing facilities.

“We took measurable steps to further enhance the company’s approach to environmental sustainability and in defining its role in making the world more sustainable,” said Paithankar.

This, Paithankar added, demonstrated the company’s progress in optimizing global operations and meet long-term sustainability goals. Therefore, the company aims to reduce its greenhouse gas (GHG) emissions by 20 percent in 2028, with 2018 as the baseline year.

Equally important, Emerson’s greening framework and solutions also play critical role to help customers and other stakeholders meet environmental sustainability requirements. Paithankar said they are working vigorously with them to identify and help implement strategies.

Besides, Emerson has a wide range of environmentally sustainable solutions to support stakeholders’ decarbonization strategies. These solutions can enable an optimized production of alternative fuels like hydrogen and biofuels, and other low-carbon power sources.

Supports Asian Enterprises

Several countries in Europe have been vigorous with their efforts to address environmental issues. Nonetheless, Paithankar said Asia is not far behind with the region’s shifting sustainability landscape.

“Asia has a strong track record of remarkable economic strength compared to other regions and is well-positioned to capture business opportunities enabled by the wave of digital transformation on implementing environment sustainability,” said Paithankar.

Especially, Emerson’s automation products, software, and expertise have been receiving favorable response from its customers across a range of industries. Paithankar said these help them achieve their sustainability objectives in operational performance, reliability, energy efficiency, and emissions management.

There are a few more technological advancements that Emerson have introduced to help enterprises, such as those in Asia, achieve their respective green undertakings. First, concerns green fuel from biomass, which is a fast-growing segment in the region. Particularly, Paithankar said Emerson’s software and systems help accelerate technology development for large-scale bioethanol and biochemical production. The first biorefinery aims to sustainably convert bamboo into fuel ethanol, biochemicals, and green power. This biorefinery targets to annually produce 60 million liters of bioethanol, 19,000 tons of furfural, 11,000 tons of acetic acid, and 144GWh of green energy.

Next, another important segment is the heating and air conditioning, which consumes a lot of energy. Particularly, Emerson’s Copeland Heat Pumps provide an energy-efficient alternative to hot water heating and space heating by delivering 75 percent energy savings compared to traditional water heating systems. Heating Solutions like Emerson Heat Pumps not only reduce heating costs but help minimize overall environmental impact.

“We see opportunities for enterprises to leverage digital technologies to transform their supply chains. With new technologies, companies can increasingly predict and detect issues, enhance safety and reliability, and enhance their business performance,” Paithankar said.