ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Omron Relays Complement Fast-Paced Manufacturing

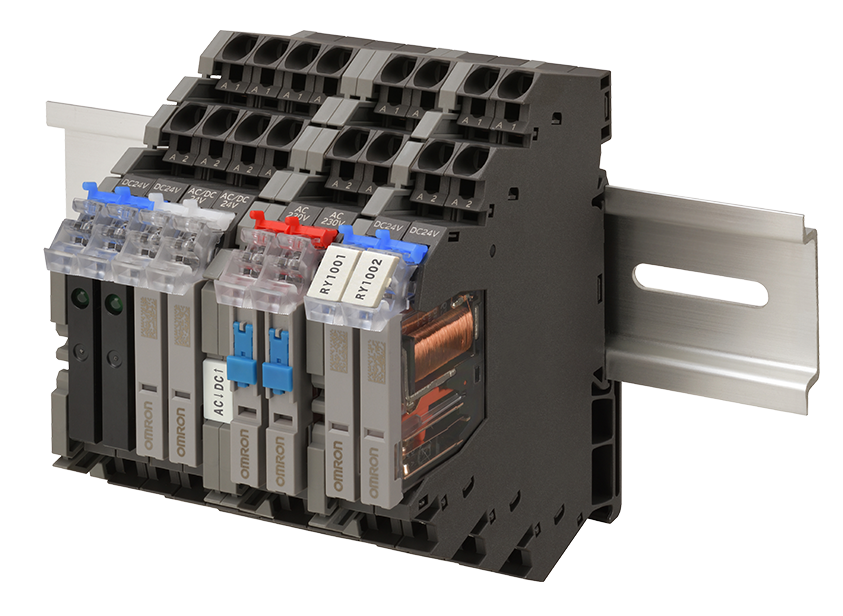

Industry-leading automation solution provider Omron Automation Americas recently introduced new G2RV-ST and G3RV-ST Slim Relays. Accordingly, these industry-leading switching speeds allow for use in a wider range of applications, including PLC outputs for heating applications and bottling lines.

In addition, aside from exceptional speeds, the G2RV-ST and G3RV-ST are notable for their slim dimensions that help customers reduce control panel footprint. At the same time, their visual status indicators make it easy to quickly confirm operation, voltage type, and relay condition.

Like other Push-In Plus technologies from Omron, the new relays are designed to resist vibration and hold wires firmly in place without the need for periodic re-tightening.

Key Features

The relays operate time of 0.2msec and release time of 0.4msec (for G3RV Solid State relay) with 6.2mm width and uniform dimensions to optimize space usage. They also come with locking lever arm and secure relay socket enclosure with robust DIN attachment.

The relays also have short bar termination feedback and integrated circuit test button

Key Customer Benefits

The relays offer better space savings in the control panel. Omron panel solutions come designed with a uniform height, depth, and component spacing to optimize the space utilized, assuaging concerns about the size of control cabinets. In fact, Omron components can save anywhere between 20-50% space inside the panel, and the slim relays have a width of just 6.2mm.

Omron slim relays also offers improved usability with design to improve the user experience with a simplified installation process and features that help identify relay status and operation.

They also offer features like a locking lever arm, secure relay socket enclosure, larger wire terminals, robust DIN attachment, short bar termination feedback, and an integrated circuit test button make slim relays easier to provide greater value and usability.

Furthermore, the relays offer excellent vibration resistance. Omron relays with Push-In Plus terminals are designed to resist vibration with a stronger hold on terminated wires, and they do not require any re-tightening over time.

Meanwhile, because the relays offer better visibility for status indicators, customers need to verify the function and status of a relay — and get other critical information about relay operation — with a quick visual check. Thus, the design of Omron relays come with visual status indicators that make it easy to confirm operation, voltage type, and relay condition.

Target Customers

The new slim relays are ideal for customers who have wide range of applications. Particularly, those who are seeking to optimize control panel space usage. Among the intended customers of the relays are food processing machines (peeling/skinning stations); packaging machinery; palletizers and de-palletizers; assembly lines; material handling systems; and robotic cells.

In addition, the relays also complement customers in power-presses; body transfer lines; folding or brake presses; filter presses; punching machines; machine tending; printing machines; and corrugating machines.