ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Latest Reflow Equipment by Tamura Boosts Production Efficiency

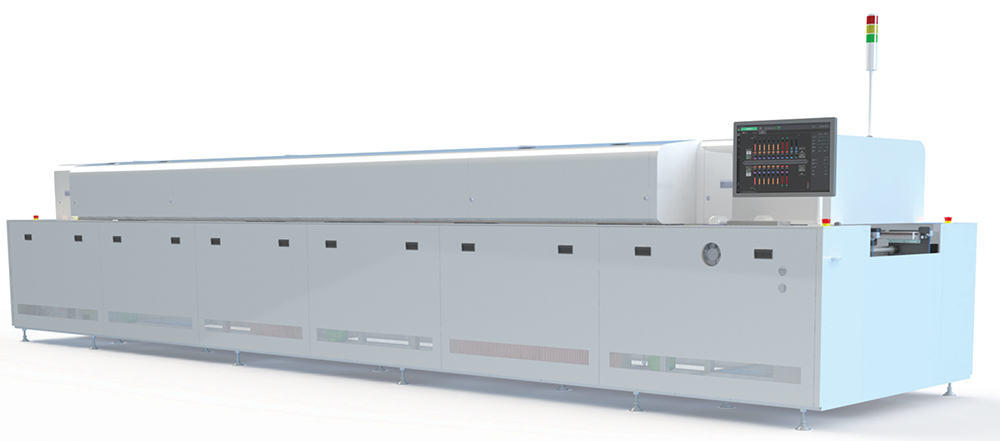

Tamura Corporation announced in 2022 the TNU-CR reflow equipment, which significantly improved production efficiency. It is fully equipped with functions presumed to be desired. Specifically, these include a function to enable high-speed automatic production changeover, dual line without a traverser, equipment management using internet of things (IoT) (big data), automatic production changeover, standardized traceability, and preventive maintenance (prevention of the stoppage of the line).

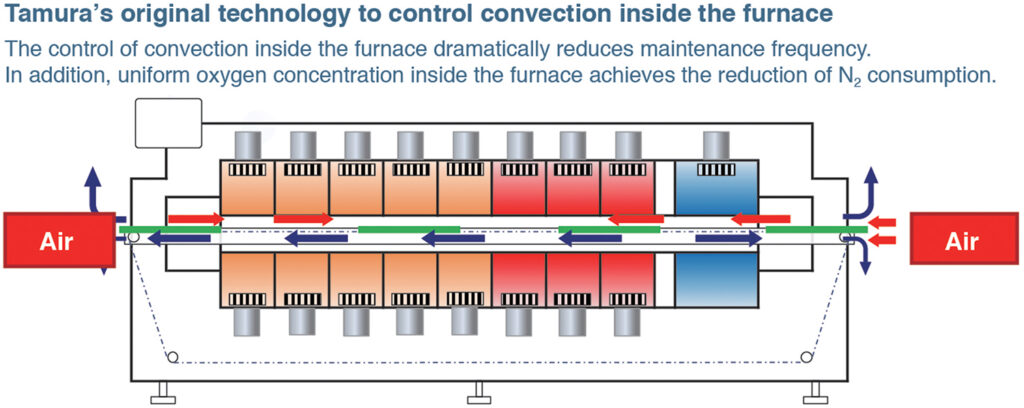

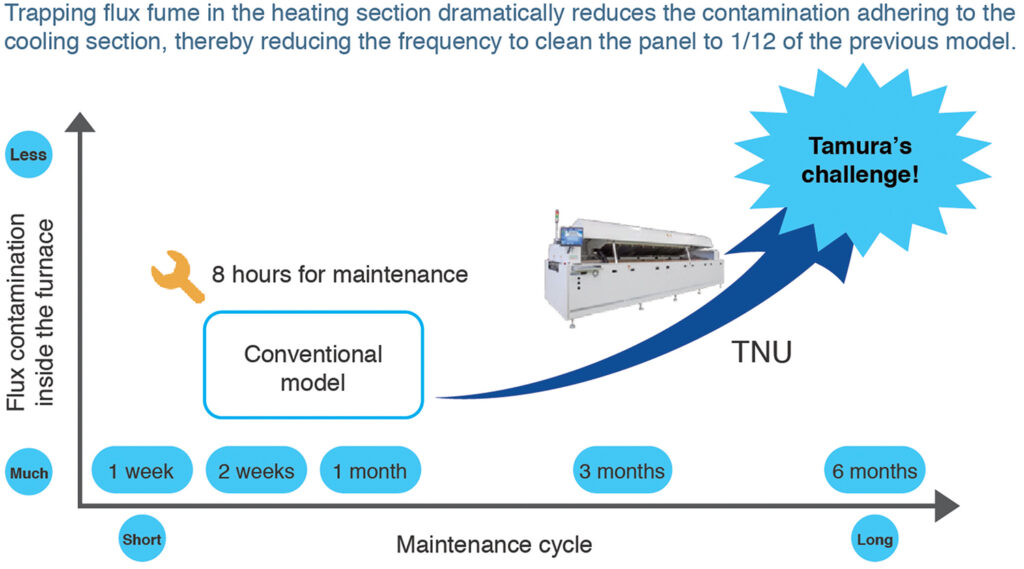

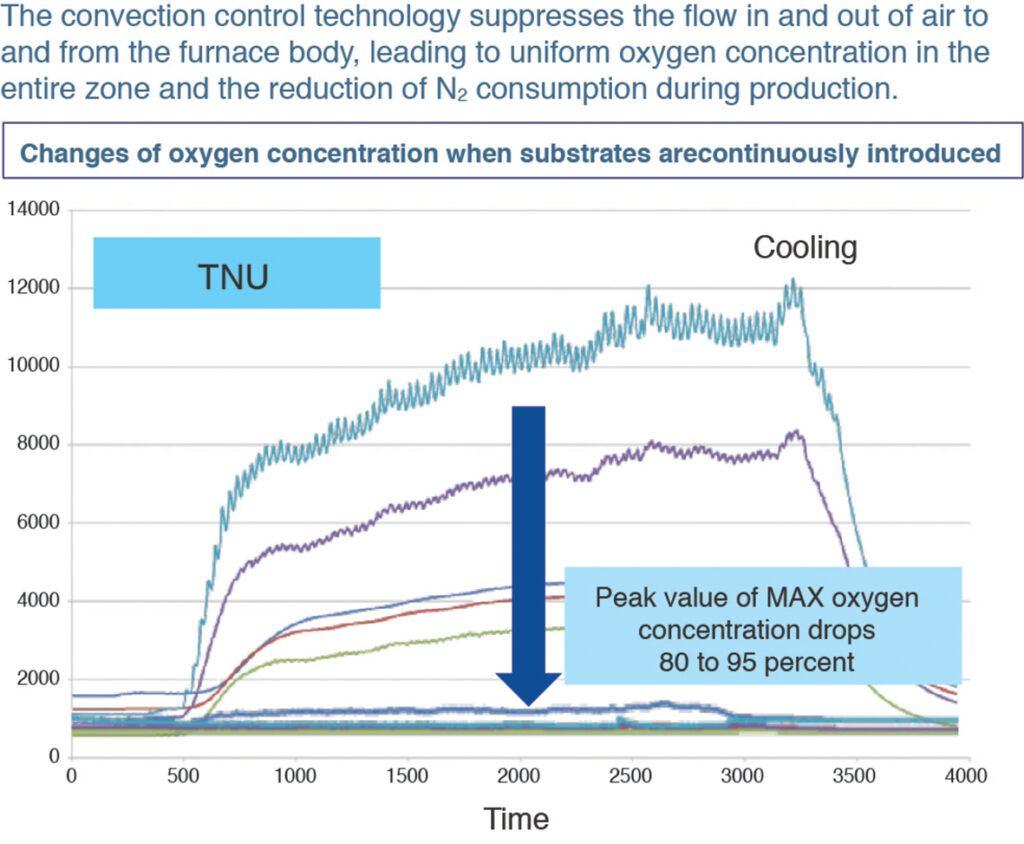

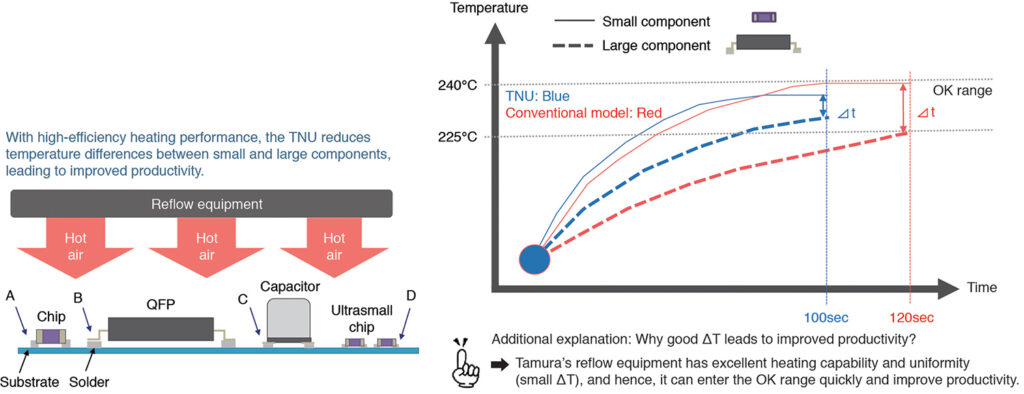

Tamura offers reflow equipment featuring high energy saving property and high area productivity. The company dramatically reduced maintenance frequency by controlling convection flow inside the reflow furnace. The control of convection flow inside the reflow furnace also led to the reduction of the consumption of nitrogen (N2). Thus, the company’s reflow furnaces continued to evolve.

The company’s most recent product is the TNV Version Ⅲ reflow soldering equipment, which features significant reduction in contamination of the inside of the furnace and has achieved dramatic productivity improvement.

Background of Development of TNU-CR, Main Features

In developing new reflow soldering equipment, Tamura focused on the following as key points: 1) improvement of production efficiency; 2) energy saving (consumed quantities of utilities, such as electricity, N2); and 3) equipment management using IoT (big data) (traceability, automatic production changeover). Tamura has materialized these key points by developing the TNU-CR.

Evolution

TNU-CR incorporates Tamura’s original temperature change system, thereby reducing the temperature change time at automatic production changeover to one-third of its predecessor. Thus, it enables dramatic reduction of the wait time before reflow at automation production changeover.

In the area of carbon neutrality, Tamura targets the reduction of greenhouse gas emissions by more than 51 percent in FY2030 compared with FY2013.

Energy saving of reflow soldering equipment directly leads to energy saving of the entire factory. Specifically, the use of low melting point solders enables energy saving of reflow equipment. In fact, such moves have been increasing.

Moreover, the adoption of low melting point solders necessitates production changeover involving temperature change from production models using ordinary solders. However, the adoption of an insulation structure, using still air to move the still air at the time of production changeover involving temperature change, enables efficient thermal exchange. Through these measures, automatic production changeover time can be reduced dramatically.

Under Tamura’s test conditions, temperature lowering and temperature raising within five minutes have been achieved for lead-free solder conventional eutectic solder containing lead (Pb). Hence, reflow does not become a bottleneck in automatic production changeover. Thus, TNU-CR eliminates 375 hours of waiting time for production annually. As result, N2 used during waiting time and the load on air conditioner have decreased, thus greatly contributing to energy saving.

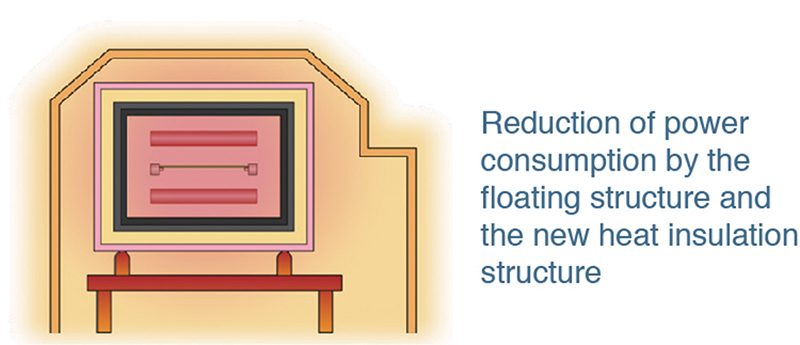

According to Tamura’s preliminary calculation, TNU-CR reduces power consumption by about 30 percent from the company’s previous model.

Automatic production changeover reduces working manhour and prevents program selection errors. Furthermore, for traceability, conditions of equipment for different printed boards produced can be recorded.

Standard functions

TNU-CR also inherits diverse standard functions. In terms of energy saving, it features 1) energy saving through improved circulating efficiency and air layer, and 2) convection interception technology (reduction of N2 consumption).

Furthermore, it also continues to adhere to technologies under the concept of “Tamura of heating capabilities”. These include furnace structure with enhanced circulation efficiency, energy saving using air layer in terms of weight reduction, and reduction of automatic production changeover time. Also, the separated motor section and the flux recovery section, and improved maintainability through elimination of tools are also characteristics of TNU-CR.

Interface feature is also easy to use. The operation screen evolved to become a customer-friendly screen.

• Customers can grasp information they want to know at a glance. Screen information sorted out, allowing operators to access what they want to know or what they want to do without hesitation.

• Icons that facilitate the resolution of points needing clarification and hint display added, allowing operators to smoothly clarify unclear points.