ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Tamura Boosts Strategies on New Energy, Automation

Aside from its mainstay products, Tamura Corporation is stepping up new initiatives to target growth markets. Masahiro Asada, President and Representative Director at Tamura, said the company is currently discussing ways to develop new products beyond its current product and market coverage and create new markets.

“Currently, decarbonization policies gain speed globally, the shift to electric vehicles (EVs) or renewable energy has been moving forward ahead of schedule. We will continue to step up the initiatives targeting growth markets,” said Asada in an interview with AEI.

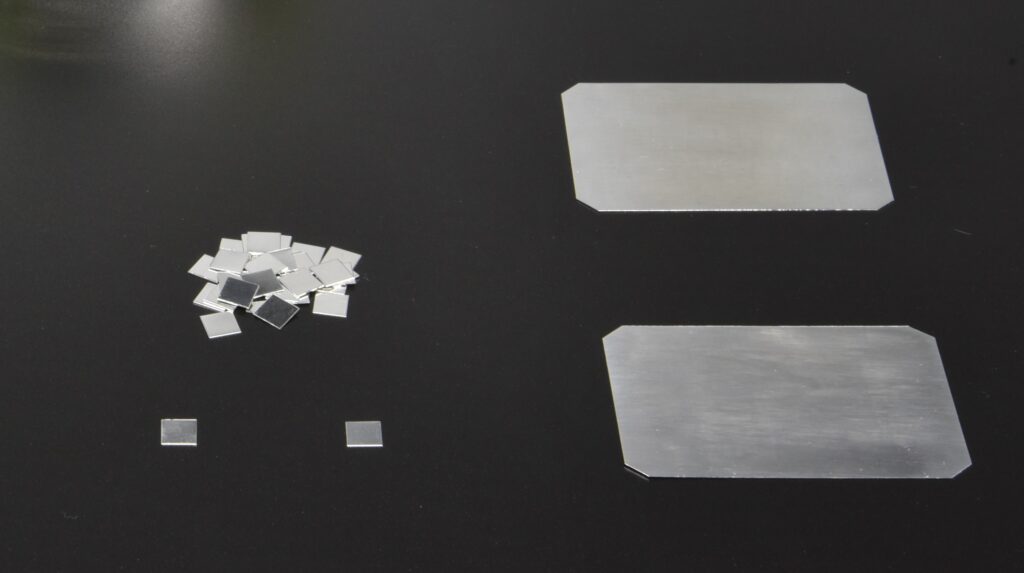

At present, the company focuses on two growth fields, which are coming from electronic components and electronic chemicals. For electronic components are highly reliable and highly efficient products for mobility market and the renewable energy market while for electronic chemicals are solder pastes, high-heat resistant solder, and solder resists for flexible substrates.

Core Business Fields

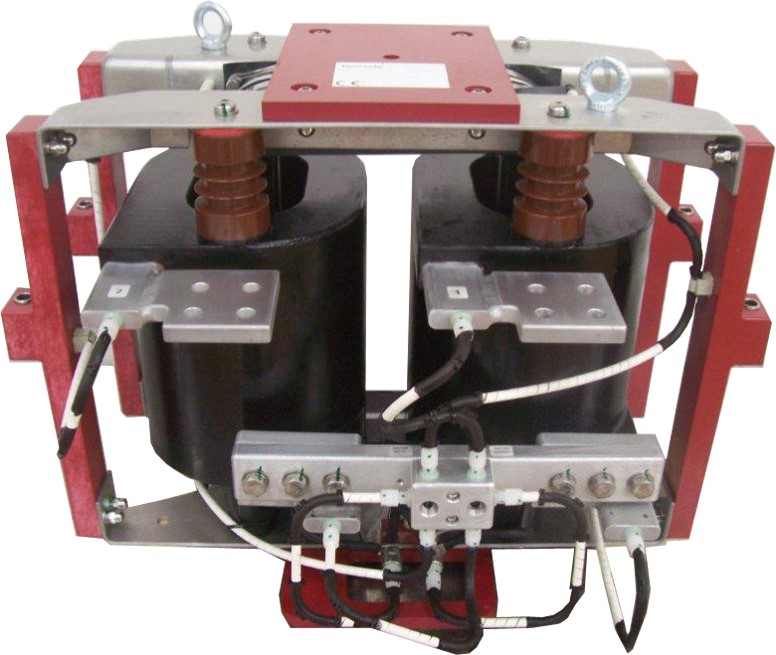

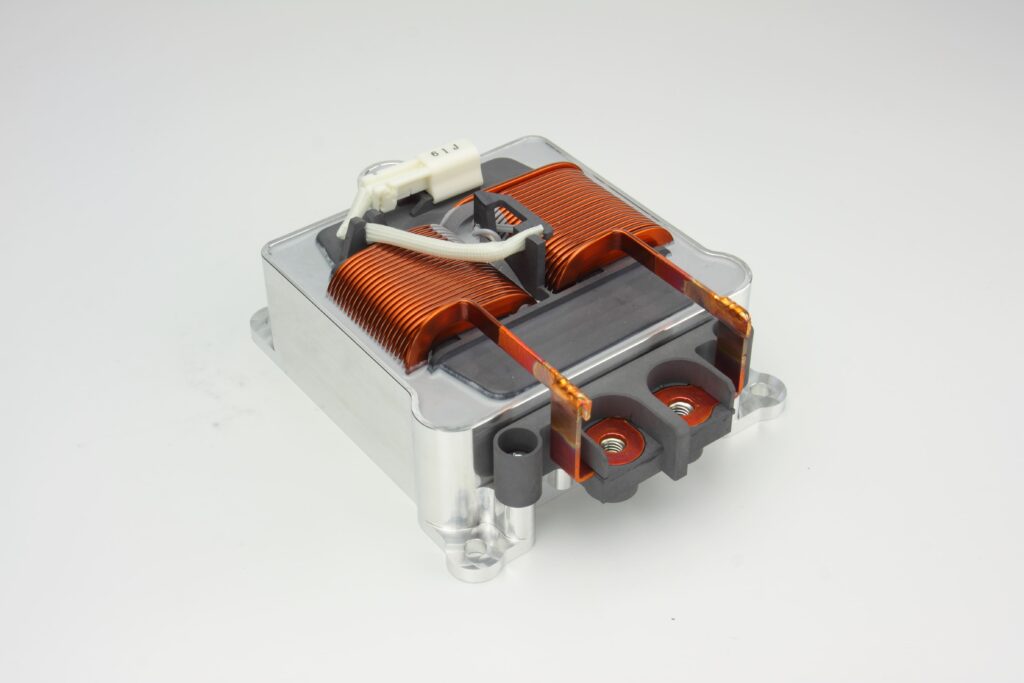

Tamura has three core business fields. For the Electronic Components business, Asada said the company is directing efforts in developing highly reliable and highly efficient products required for power systems that deal with high current, such as eco-friendly cars, renewable energy, and industrial. Particularly, the company will enhance production capacity for boosting reactors for eco-friendly cars.

Meanwhile, it will also heighten production for gate driver modules for power semiconductor control. This as gate driver modules are important for solar and wind power generation, electricity storage, in-vehicle equipment for electric vehicles, and motorization.

For the Electronic Chemicals/FA Systems business, Asada said they offer materials that are not only highly reliable, but also possess high heat and humidity resistant even in harsh engine room environment. Furthermore, Asada said they also provide materials that support advancements in mobile devices and wearable devices, particularly with the advent of fifth generation (5G) mobile network standard. In addition, the company aims to respond to needs of customers

“Specifically, we aim to achieve customer satisfaction through the development, manufacture, and sales of highly reliable solder pastes, including high heat-resistant solder, solder resists for flexible substrates that realize high functionality,” said Asada.

On the other hand, for the Information Equipment segment, aside from its audio adjustment console, which are popular in Japan’s TV and radio broadcasting, the company has introduced the NTX Series.

Supports Industry 4.0, Decarbonized Society

Tamura has been propelling its high-performance soldering systems, which are compatible with other assembly equipment. Asada noted such systems are becoming popular in production floors due to increasing demand for in-vehicle printed circuit boards (PCBs) associated with advances in automotive electronics. Furthermore, these systems are necessary to implement smart manufacturing systems in support of Industry 4.0 initiatives.

“Our systems show good environmental performance that helps save power and resources. Using this advantage, our systems streamline mounting lines and support manufacturing in evolving factories around the world,” said Asada.

Recently, more manufacturing companies are aiming net-zero carbon emissions and Asada said Tamura introduces products that contribute to reduced carbon footprint.

“With the realization of a decarbonized society in mind, we need to come up with new products and services, follow the business trend toward attaining carbon neutrality, and link that initiative to a new business strategy by setting a big goal,” said Asada.

The Tamura Group started what it calls unified environment management system way back in 2006. Since then, it was able to integrate to the system 23 sites of 16 companies, enhancing their environmental performance.

Furthermore, as it keeps an eye towards its carbon neutral goals by 2050, the Tamura Group is on track to achieve its 2030 target of reducing greenhouse gas emission by 51 percent or higher compared to 2013 level. In addition, it is also on course to achieve its 2030 target of doubling its amount of renewable energy introduced compared with 2019 level.

“To attain sustainable growth and realize a sustainable society, the Group will work on saving energy and leveraging renewable energy thoroughly,” said Asada.