ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

OMRON to Release New Motor Condition Monitoring Device

OMRON Corporation will globally launch the K7DD-PQ Series advanced motor condition monitoring devices, starting March 1 in Japan and on April 3, globally. The series is the latest addition to OMRON’s family of condition monitoring devices. Specifically, these devices automate the monitoring of abnormalities on the manufacturing site in place of human workers. Also, K7DD-PQ numerically track trends in the deterioration and wear of servomotors, machine tools, and other equipment. Mainly, this process reduces inspection effort and prevent the tools’ unexpected failure.

With labor shortages intensifying in the manufacturing industry, the demand for the automation and streamlining of maintenance work is heightening. On manufacturing sites, monitoring of the conditions of servomotors, which frequently change speed, and of motors on equipment with frequently changing loads (e.g., machine tool drills) previously relied on skilled veteran workers. Particularly, inspections and part replacements had to be conducted based on the experience and knowledge base of these workers. Also, the need to implement solutions that prevent unexpected equipment downtime is increasing.

To address these issues, OMRON began providing condition monitoring devices in December 2017. These devices implemented OMRON’s industry-leading sensing technologies and anomaly detection algorithms to monitor for equipment anomalies. Consequently, downtime losses on the manufacturing site are eliminated. Since then, the company paved the path toward predictive maintenance solutions for monitoring 3-phase induction motor*1 conditions, thermal control panel monitoring, motor insulation resistance*2 monitoring and monitoring deterioration trends in resistance heaters.

Monitors Wide Range of Failures

The new K7DD-PQ monitors the conditions of servomotors that frequently change speed, and of motors with rapidly changing loads. Additionally, they are able to monitor a wide range of failures individually by monitoring over 400 types of features*3 from current and voltage measurements. Machine tool spindle motors for drilling, for example, can fail in many different ways: their blades may become worn, chips may get caught, their bearings may deteriorate, and so forth. As a result, inspection of these motors must be done for each of these possibilities.

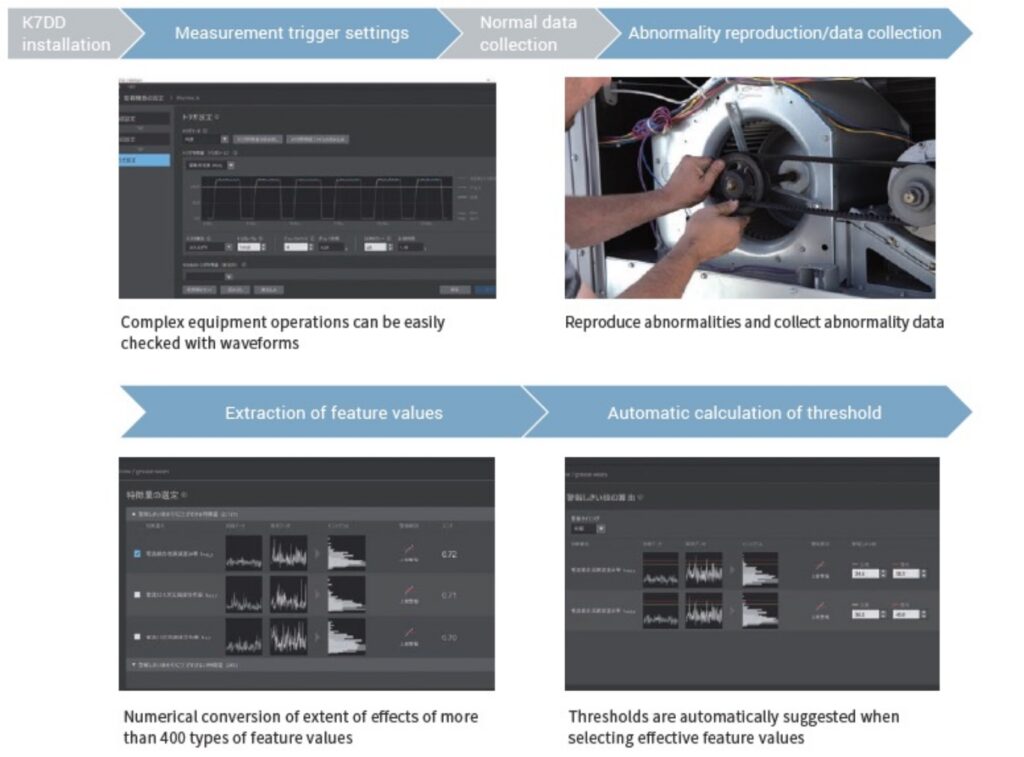

Additionally, K7DD-PQ allows advance configuration to monitor for each failure mode separately. They also set thresholds automatically based on data collected by the support tool. These features allow for the automation and streamlining of maintenance tasks, which are previously reliant on the experience and senses of skilled veteran workers, in order to prevent unexpected equipment failures.

By evolving its unique “i-Automation!” concept, OMRON will continue to pursue new ways to achieve productivity suited for manufacturing of a future age. This will be powered by “Autonomation beyond Human Ability” and “Advanced Collaboration between Human and Machines.” The company’s aim is to drive this productivity by innovative digital engineering, together with its customers, through the expansion of its lineup of condition monitoring device products.

Main Features of the K7DD-PQ Series

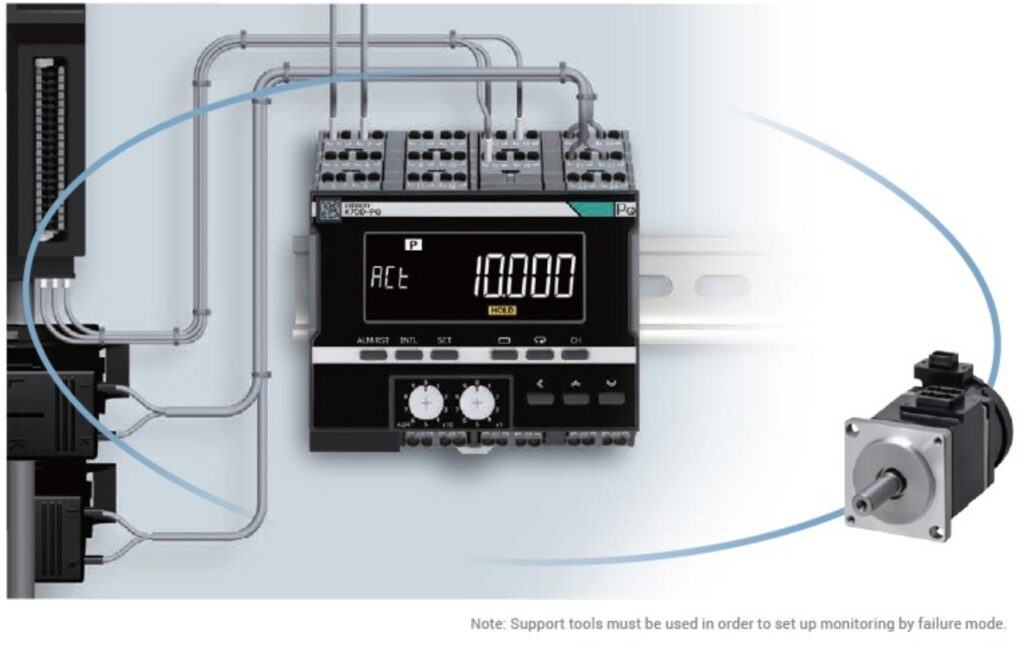

Specifically, K7DD-PQ advanced motor condition monitoring devices monitor the conditions of the entire motor equipment by obtaining current and voltage measurements through the motor’s power line. The applied technologies are as follows: 1: High-speed 2.5-μs sampling technology that catches even the most fleeting anomalies; 2: 6-channel simultaneous/continuous operation technology that processes data without omission or deviation; 3: 50-ms operating speed that keeps pace with variable-speed equipment; and 4: Capacity to monitor over 400 types of feature values that enables exhaustive diagnosis of motor equipment.

1. Enables monitoring of servomotors and induction motors that frequently change speed

Anomalies in a motor or its load often impact the motor’s rotation axis. Gaps between the rotor and stator and changes in torque stemming from deterioration manifest as changes in current and voltage, causing waveform distortion. K7DD-PQ monitor diverse feature to distinguish between vibrations to the motor, impact to the motor, and changes in torque.

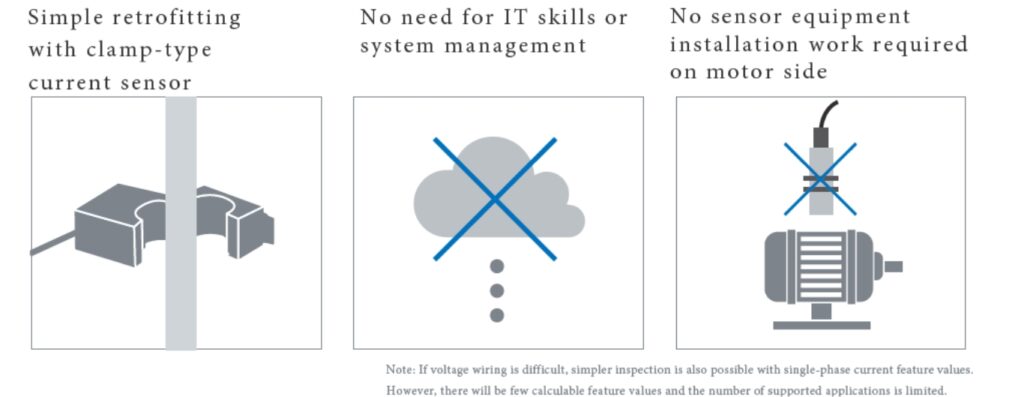

2. Delivers condition monitoring that can be self-contained within the manufacturing site

Using the cloud and data servers requires system building skills and coordination with IT administrators. More so, condition monitoring using conventional vibration sensors requires construction work for installing these sensors to the equipment to be monitored. K7DD-PQ can be retrofitted to the control panel to let users monitor motor equipment conditions and view anomalies locally without having to learn new skills. By using host communications systems, users also distinguish between different failure modes when alerts are issued by a K7DD-PQ.

3. Reduces inspection workload and delivers results reliably

K7DD-PQ are equipped with 50-ms operating speed. It has the capacity to calculate over 400 types of feature values, allowing them to identify many different failure modes of motors. Using this data requires advanced data analysis skills. The series offers a support tool that simplifies this analysis. It selects effective feature values and sets thresholds automatically to identify failure modes and root cause.

*1 3-phase induction motors: Used in equipment such as pumps and fans, these motors are the most commonly used motors in factories and similar settings.

*2 Insulation problems: State in which insulation material for preventing electricity from leaking from the electrical circuit to the chassis has deteriorated, allowing electricity to leak. Insulation problems can lead to incidents that gravely impact equipment safety and productivity, such as electrocution, fire, and failure.

*3 Feature values: Values operated from current and voltage data obtained from the motor’s power line. These values are used to explore the correlation between this data and changes in motor conditions.