ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Shin-Etsu’s Unique Technique Lifts Micro LED Displays

Shin-Etsu Chemical Co., Ltd. has developed new process technologies that will advance the manufacturing of micro LED displays.

The size of a micro LED chip is not visible to the naked eye, with the length of one side being less than 50μm. For example, to manufacture one 4K display that has four times the resolution of a conventional high-definition screen, it is necessary to precisely array about 24.90 million chips.

Shin-Etsu Chemical has been working together with Shin-Etsu Group companies to take advantage of unique materials technologies. Hence, it was able to implement improvements in the complexity and yield ratio in the processes of micro LED chip manufacturing and the transfer process of each chip.

Easing Manufacturing Challenges

Recently, the company said it has proceeded to develop various advanced innovative transfer equipment and transfer parts to solve key manufacturing challenges of micro LED display manufacturing. Particularly, the company has been working closely with Dexerials Corporation. This led to innovative technology that will transfer singulated anisotropic conductive film (ACF) of Φ80μm or less onto the targeted location by laser equipment.

Employing this technology, it becomes possible to transfer the singulated ACF only to the designated plate and mount the micro LED chip on it. Thus, making the repair process in micro LED display manufacturing easy to carry out, a matter which had been a large issue up until now.

In addition, the company also stands to meet the requests of customers achieving further improvements in productivity and in the handling of a wide variety of chips. Shin-Etsu Chemical is working in cooperation with two Shin-Etsu Chemical Group companies, Shin-Etsu Engineering Co, Ltd and Shin-Etsu Polymer Co., Ltd. Thus, the collaboration was able to develop the transfer equipment and transfer parts. At the same time, expanded its products line-up.

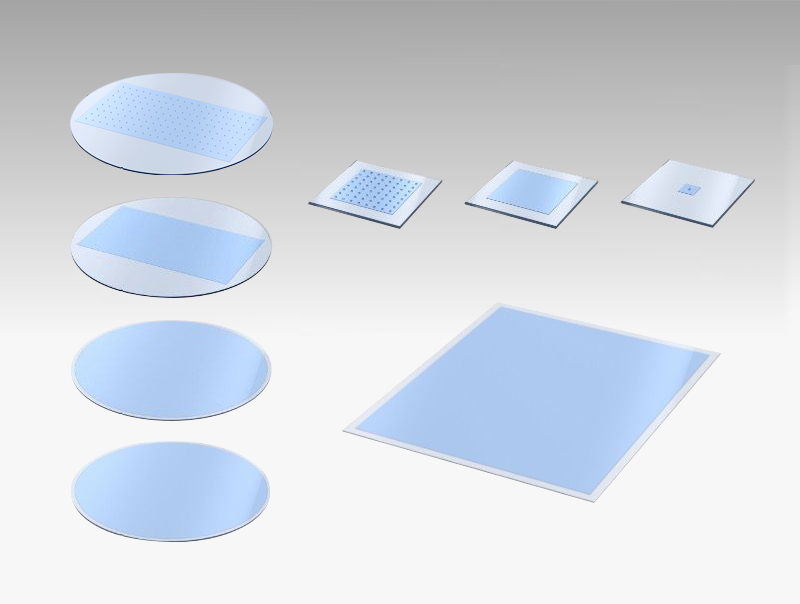

Combining the advantages of these Shin-Etsu transfer equipment and transfer parts, the company aims to be able to offer the most optimized manufacturing processes to our customers. These include the SQDP-B Series, cure type donor plate and the EZ-PETAMP Series, multi-stage dot-type large stamp (6 inches). In addition, the Invisi LUM-X4, a 4-in-1 system that makes it possible to perform 4 processes using 1 laser and the BM encapsulant film for Mini LED displays.

One-Stop Solution Provider

Shin-Etsu Chemical, as a “One-stop Solution Provider” in micro LED manufacturing, will propose to customers’ solutions to the key challenges presented in the manufacturing processes for Micro LED displays. Furthermore, it will work to spread the popularity of next-generation Micro LED displays and to expand its position in the display market.