ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ASMPT's Open Automation, Novel Software, Draw Crowd

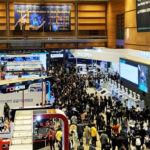

ASMPT took note of the industry’s renewed interest to data analytics, software innovations, as well as its print platforms. Accordingly, these are the same reasons why professionals trooped to the company’s booth at the recent IPC APEX Expo event in San Diego, California, which made record number of attendance back to pre-pandemic levels.

ASMPT Americas Marketing Manager, Mark Ogden said the company’s customers have been wanting to improve throughput and quality. However, they are also facing challenges of finding and retaining qualified personnel. “This strains traditional working models and highlights the necessity for reliable, open automation, simplified interfaces, and at-your-fingertips data. ASMPT has all aspects covered.”

Most importantly, Ogden said these are the factors why their recent APEX exhibit turned out an overwhelming success.

Software Ingenuity Steals Show

While intrigued by market-leading placement and printing hardware solutions, ASMPT show delegates also unanimously expressed their requirement for open communication protocols. In addition, they are also looking after intelligent production line oversight, actionable data analytics, and on-the-fly assistance.

Visitors were able to try first hand several new offers in these areas. The company’s WORKS shop floor/line level management suite allows customizable and scalable integration. Thus, enabling manufacturers to add features as needed.

Among the newest additions is WORKS Material Demand Calculation (MDC), which dynamically assesses materials required on the line, and adapts to changing conditions in real-time instead of supplying to static, pre-production expectations.

Other sought-after software solutions at APEX were newly-launched Virtual Assist and SMT Analytics. Particularly, SMT Analytics provides deep data collection and analysis for actionable manufacturing improvements, leveraging ASMPT equipment data and correlating it using a Critical Manufacturing MES module.

When operational troubleshooting or maintenance instruction is required, Virtual Assist uses voice recognition to deliver relevant video and documentation assistance for ASMPT equipment. This new technology integrates with the company’s online Academy training platform.

Award-Winning, Uninterrupted Operation

Before the show’s opening, ASMPT’s DEK TQ L stencil printer was already logging wins. Accordingly, the brand-new platform secured a first-place finish in Circuits Assembly magazine’s NPI Award contest, edging out competitors in the stencil printing category.

With a smaller footprint, faster cycle time, robust construction, and exceptional accuracy, TQ L demonstrations were in high demand throughout the three-day APEX event.

Most importantly, the printer has a dual-cover design for hot-swappable solder paste replenishment and expanded consumables capacity to allow full shift production without assistance.

When paired with Process Expert AI capabilities, TQ L can self-correct and optimize print parameters for even greater efficiency.

Finally, at the center of the ASMPT exhibit were the company’s flexible and scalable SIPLACE SX and SIPLACE TX placement platforms. Moreover, they continue to lead the electronics sector with performance and reliability. The company has seen significant Americas market share growth in recent years, with placement equipment and corresponding software ingenuity fueling these positive results.

“Electronics content is growing across almost every product category,” concludes Ogden. “This reality, combined with ever-changing market geographics, highlights the need for reliable, intelligent, fast, cost-effective factory solutions. Customers now see these capabilities as non-negotiable competitive differentiators. ASMPT did not disappoint, and our record-setting attendance further confirms that we have invested in all the right places.”