ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Framework Emerges in Creating IoT System

Specifications of devices needed for implementing internet of things (IoT), such as sensors and communication devices, differ from manufacturer to manufacturer. Therefore, users must select devices for themselves to construct an IoT system.

Particularly, easy-to-use sensing devices are indispensable for the proliferation of IoT. As such, efforts to create a connection mechanism, including standard setting, has gotten under way targeting to create a composite measuring system that can be made by freely combining multiple sensors.

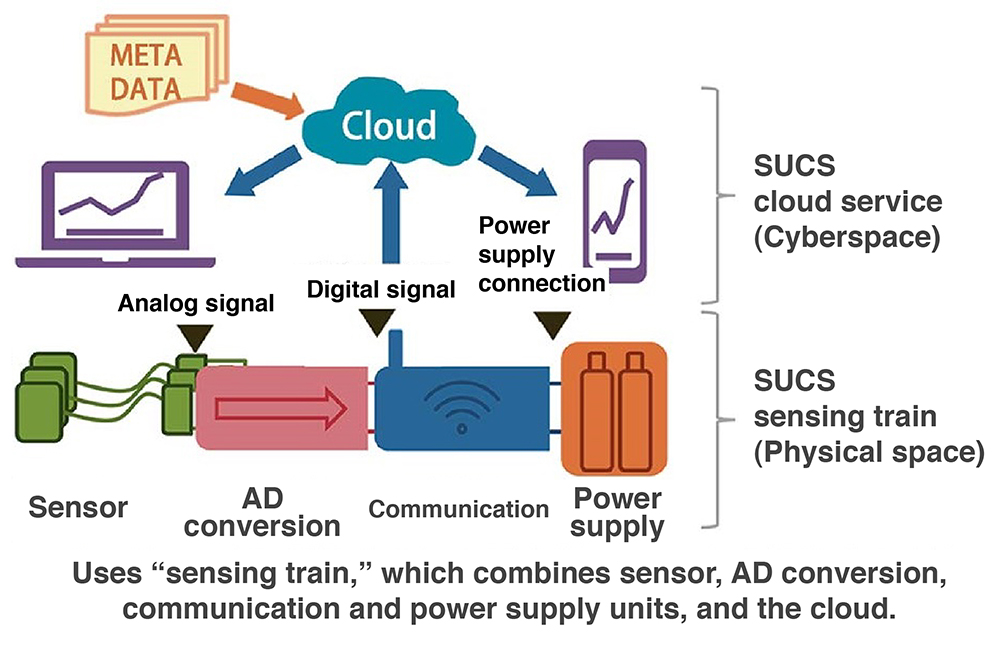

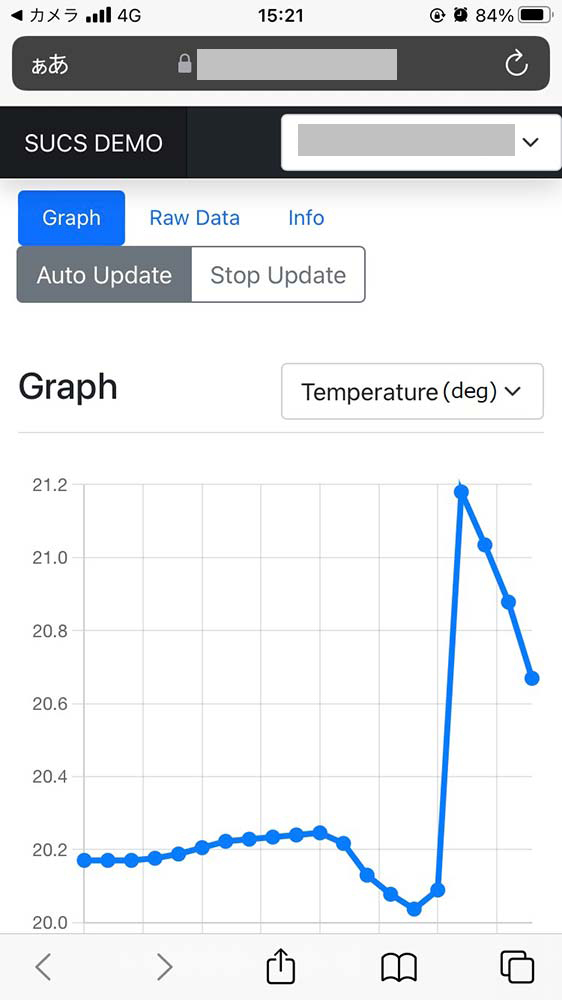

Senspire Universal Connecting System (SUCS) has been conceived as a new framework for IoT sensing. It enables analog signals of sensors to be converted into digital signals and sent to the cloud. Thus, allowing collection and utilization of diverse sensor data easily.

The SUCS Consortium, a research group under the Japan Society of Next Generation Sensor Technology (JASST), works on standard setting for and promotion of SUCS. Particularly, JASST works to propel the development of sensor technologies.

Metadata Plays Role

The specific feature of SUCS is similar to connected body of units, called sensing train. Sensing train is a unique module, which can freely connect the basic four units. Namely, sensor, analog-digital conversion, communication, and power supply units. Azbil Corporation has acquired a patent on the sensing train system. Members of the consortium are allowed to use the system free of charge.

First, a user selects sensors for measuring targets, such as temperature, humidity, light, pressure, and distance. At this time, exchanging units enables the system to easily support different measuring targets, allowing for composite measurements. This is the most salient feature of SUCS. For example, AD conversion unit can be selected in accordance with the updating cycle of measurement data and resolution.

As expected, communication unit should suit various communications standards, such as low power wide area (LPWA). Most importantly, fourth-generation (4G) and fifth-generation (5G) communications standards as well as Wi-Fi. Connecting these units and receiving the authentication on the cloud enable the use of the sensing system immediately. Thus, no programming is necessary.

The use of metadata has enabled the ease-of-use, which can be said as epoch-making. Metadata indicates various attribute information relating to the SUCS framework.

The attribute information comes in two types: fixed data of the sensor unit, such as model, manufacturer name, mass, and output unit; and sensing data-derived information, such as data name, creator name, and observation target and period. Metadata is additional information relevant to “properties of data” compared with measurement information obtained through sensing.

When a manufacturer who supplies each unit registers metadata, the administrator gives a grant number. A user of sensing train registers the grant number and metadata of the sensing train on the cloud using QR code or other means. Then, the user can use sensing data after metadata is deployed on the cloud.

Evolves in Cyberspace, Physical Space

With increasing measurement cases, metadata becomes enhanced and gradually accumulates on the cloud. At the same time, sensing train can be expanded by increasing the number of connected units.

Hiroyuki Furukawa from Azbil Corporation, and is secretary general of the Consortium, explains SUCS as “a system that evolves in both the cyberspace and the physical space.”

The SUCS Consortium has seven member companies. They are KOA Corporation, which supplies wind-velocity sensors; NAGANO KEIKI CO., LTD., which supplies pressure measuring devices; Nisshinbo Micro Devices Inc.; Easy Measure; NEW COSMOS ELECTRIC CO., LTD.; AR’S Co., Ltd.; and Azbil.

Going forward, they will call system integrators that develop cloud systems and apps to participate in the Consortium. In addition to manufacturers that handle sensors, measuring instruments, communications equipment, and power supplies. They also hope the participation of SUCS user companies and companies that provide services using SUCS.

Presently, the SUCS Consortium is working to set specifications, including electrical and mechanical connection methods, and communication standards. It plans to release its first guidelines to the public in June.

For the spread of IoT, the expansion of human resources that are involved in sensing is indispensable. SUCS member companies anticipate that a sensing mechanism that require no special knowledge and can be used readily by anybody will give rise to sensing technologies and services based on completely new ideas.

Meanwhile, Akira Kobayashi, professor emeritus of Tokyo Institute of Technology, who serves as the head of the Consortium, said, “SUCS pursues ease-of-use for users. I hope it becomes a mainstream as a new sensing system.” The Consortium aims to cultivate a huge sensor market.