ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Stratasys Bags New Deal with German Manufacturer

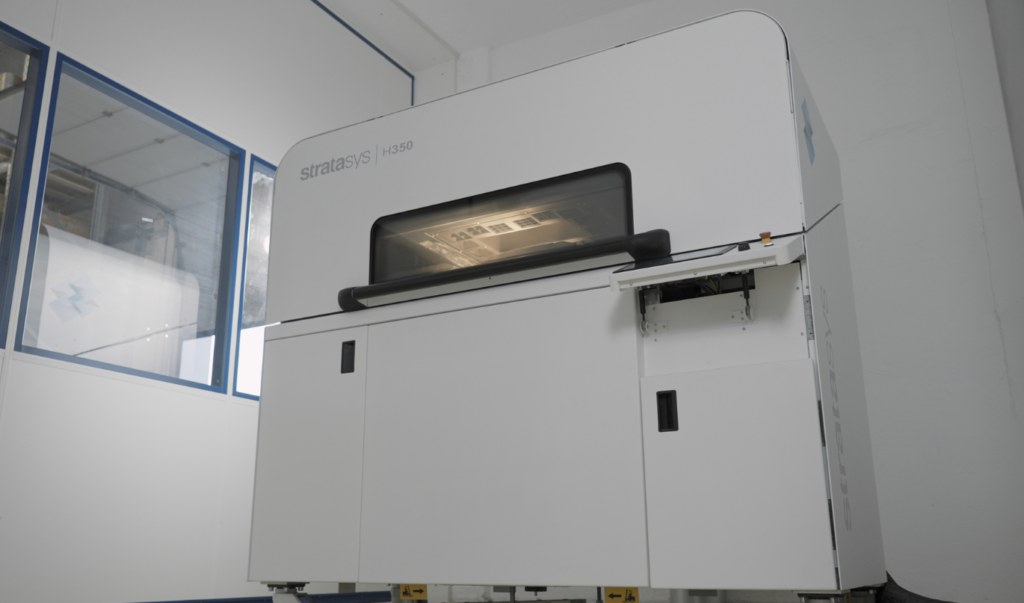

Polymer 3D printing solutions provider Stratasys Ltd. said German service bureau Götz Maschinenbau has invested in four additional production-scale Stratasys H350™ 3D printers. Accordingly, the new investments would help the company meet growing customer demand for high-quality end-use parts.

The investment will ramp up Götz’s total fleet size to six systems. The new units, to be installed over the next 18 months, position the company as the leading service bureau for SAF™ technology in EMEA.

Quality, Cost Effective Printer

Götz, which also deploys Stratasys 3D printers based on PolyJet™ and FDM® technologies, is a specialist in the turning, milling, welding, and assembly of parts. In addition, it serves customers across a range of industry sectors, among them automotive, mobility and mechanical engineering.

Most importantly, adding the ability to additively manufacturing thousands of polymer parts has represented a significant growth opportunity for the company.

Philipp Götz, Owner, Götz Maschinenbau, said the SAF technology used by the H350 systems is ideal for maintaining the high quality yet cost-effective standards expected by its customers.

X1“Since the installation of our initial H350 printers, we’ve actually won significant new business because of the quality and cost-effectiveness of parts printed on SAF technology,” he said. “Our existing Stratasys 3D printers are operating at full capacity 24/7 and provide us with an extremely reliable manufacturing solution for high volume, as well as small to medium series production, at a lower price and with shorter lead times than injection molding or CNC,” he added.

Wide Range of Volume Production Applications

The Stratasys H350 3D printer’s design is to deliver production-level throughput for end-use parts. Furthermore, it enables providing production consistency, competitive cost per part, and complete control over the production of thousands of parts. In fact, the printer itself comes equipped with around a dozen parts 3D printed with SAF technology.

“Whether we 3D print five parts or tens of thousands, the consistency of each part is the same across the entire order. Thus, ensuring that they can be built directly into machinery and address a wider range of volume production applications,” continued Philipp Götz.

Essential to Götz’s ability to deliver production-grade plastic parts at high-volume is the Stratasys® High-Yield PA11 material for the H350 printer. The bio-based plastic’s made is of renewable raw materials derived from sustainable castor oil. In addition, enables a high nesting density while maintaining part consistency. Götz has also been an early user of PA12 material, which produces stiffer parts.

At volume, SAF™ PA12 allows for fine feature resolution, strength and accuracy build after build, and is most suitable for higher tolerance requirements such as for assemblies and connector applications.