ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Samsung Electro-Mechanics Develops Highest-Capacity MLCC for EVs

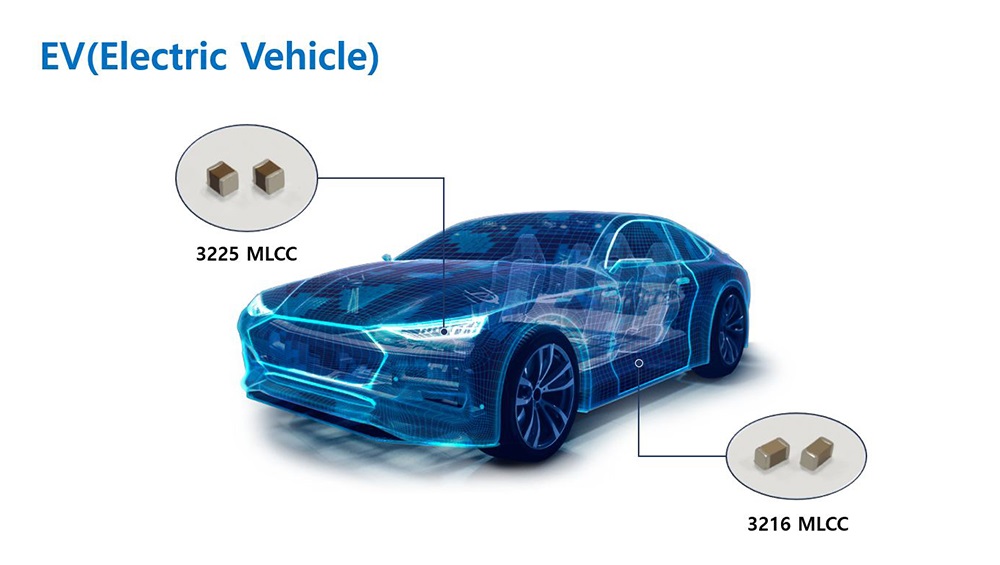

Samsung Electro-Mechanics attained the industry’s highest capacity high-pressure multilayer ceramic capacitor (MLCC) for electric vehicles (EVs). The company is now expanding its product line up for high-end level automotive electronic components.

MLCC is a component that controls the constant and stable flow of current in circuits of electronic products. It is widely used in smartphones, PCs, IT devices, home appliances, automobiles, 5G, and IoT-related products. In particular, automobiles are equipped with at least 3,000 to 10,000 MLCCs for power delivery, safety, driving, and infotainment.

High-Capacity MLCCs

The new MLCCs feature 250V class 33nF with low capacitance change rate according to temperature and 100V class 10µF for 125℃. Specifically, these products feature the industry’s highest capacity in terms of high-pressure MLCC in the same voltage class. Each product is used in electric systems and LED headlamps, which are key devices for EVs.

EVs operate based on high-voltage battery systems, such as battery management systems (BMS) and on-board chargers (OBC).

MLCCs used in EVs must be able to withstand the high output voltages transmitted from the battery for ultra-fast charging and power delivery. In addition, as the number of electronic components used in electric vehicles increases, semiconductors must also have high-capacity characteristics so that they can operate stably.

Specifically, the 250V class · 33nF product boasts the highest capacity in the industry at the same voltage level. Previously, 22nF was the highest capacity for the existing 250V class products. Moreover, this new product improves battery stability. The high-frequency noise was removed inside the battery module while having the durability to withstand high voltages.

In addition, the 100V class · 10µF product is used in LED headlamps for electric vehicles. Its electric capacity has been doubled compared to the previous product.

Semiconductors used in LED headlamps require high power consumption. So high-capacity MLCCs that can store a lot of energy and supply it to semiconductors quickly and stably while having high voltage durability are essential.

Refining Dielectrics

In general, satisfying both voltage and capacitance characteristics in MLCC at the same time is difficult. Designing thicker dielectrics to increase voltage characteristics reduces the number of internal electrodes that can be stacked, making it difficult to increase capacity. Samsung Electro-Mechanics has realized high capacity by refining dielectrics as core raw material in the form of nano-level fine powder. The company also explained that its proprietary surface coating method minimizes agglomeration between powders, enabling stable operation at high voltages.

Meanwhile, the MLCCs developed this time satisfies AEC-Q200, a reliability test standard for automotive electronic components. This standard enables them to be used in other applications, such as ADAS, body, chassis, and infotainment in vehicles.

Samsung Electro-Mechanics CEO Chang Duckhyun, said, “Samsung Electro-Mechanics has established the whole line-up for automotive MLCC by developing electric vehicle products. (Further), it will develop and manufacture core raw materials for MLCCs on its own to enhance technological competitiveness. It will expand its market share for electronic device MLCCs by internalizing facilities and strengthening production capacity.”

Samsung Electro-Mechanics has been developing and producing MLCCs since 1988. It holds the world’s second-largest market share in the IT sector. Samsung Electro-Mechanics is strengthening its lineup of high-temperature, high-pressure, and high-reliability electronic device products based on its technological prowess in the ultra-small and ultra-high-capacity MLCC sector. Moreover, it is expanding its MLCC supply to global automotive component manufacturers and automobile manufacturers.

Samsung Electro-Mechanics has newly established organizations dedicated to automotive electronic components in its major business divisions following the expansion of the automotive electronic components market. It aims to continuously develop technologies for automotive electronic components in areas such as MLCC, camera module, and semiconductor package substrate, and is expanding its business proportion.

Last March, Duckhyun said at the shareholders’ meeting, “Electric vehicles and autonomous driving are opportunities for Samsung Electro-Mechanics. We will emerge as an automotive component company by joining the development trends of automotive electronic components market.”