ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Macnica’s New Solution Boosts Predictive Maintenance

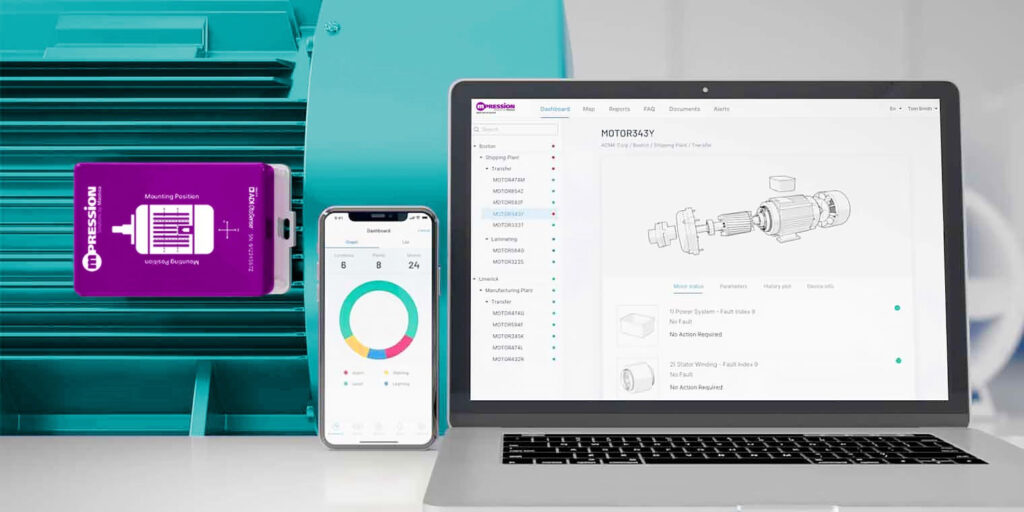

Macnica, Inc., a total service and solution provider in semiconductors, networks, cybersecurity and AI/IoT, has launched the Mpression Smart Motor Sensor. Particularly, the predictive maintenance solution comprises of products developed by Analog Devices, Inc in Taiwan.

A subsidiary of Macnica, Answer Technology Co., Ltd., sells Mpression Smart Motor Sensor in Taiwan. Moreover, Mpression Smart Motor Sensor can be applied to industrial automation, predictive maintenance, and monitoring.

Macnica Smart Motor Sensor

The Macnica Smart Motor Sensor is an OEM solution, consisting of hardware equipped with an ultra-high-precision MEMS sensor developed by Analog Devices. In addition, it has dedicated software. Hardware installation is possible by attaching a battery-powered sensor to the cooling fin of the motor. A smartphone app can configure the initial settings.

Once in use, it automatically initiates AI machine learning, and an AI model to detect anomalies will be automatically generated after a period.

This allows the vibration, temperature, and magnetic field data to be collected by the sensor to be checked via PC, smartphone or tablet with alerts sent in the event of an abnormality.

There are 9 detectable types of motor anomaly, each analyzed with an independent normal value of 0 – 10, allowing predictive maintenance to minimize catastrophic failure and downtime, without any special knowledge of vibration analysis or AI.

9 Types of Motor Anomaly

Below table shows the nine types of motor anomaly:

| Power system | Motor shaft / Balance | Alignment |

| Stator winding (insulation diagnostics) | Eccentricity (air gap) | Cooling system |

| Rotor | Bearing | Mechanical wear |

The timing for maintenance, repair and overhaul can be optimized looking at the data and performed during regular operating hours, thereby reducing maintenance costs while preventing downtime. For that reason, optimizing maintenance and overhaul leads to optimal motor operation, and efficiency in manufacturing processes. This is possible even where motors in the factory cannot be stopped, or where stopping would have an impact on business.

Macnica has systematized the Digital Synergy Factory (DSF), a service for next-generation smart factories that utilizes the knowledge and latest technologies in the manufacturing industry. At the same time, will extend its support to the field of predictive maintenance with the provision of the Macnica Smart Motor Sensor. For further information on this can be found on Macnica’s website.

*Graphic/Image used courtesy of Business Wire