ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

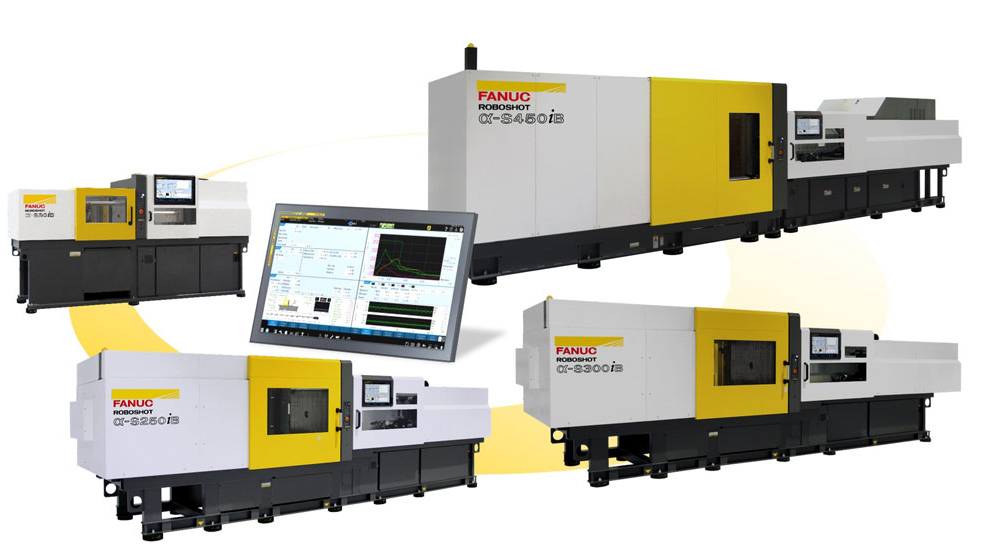

FANUC Releases New Models of ROBOSHOT α-SiB Series

Leading robot manufacturer, FANUC Corporation has released new models in its ROBOSHOT α-SiB robot Series. Specifically, these models are α-S30iB, α-S250iB, α-S300iB, and α-S450iB. The α-S30iB has a clamping force (CF) of 300kN; α-S250iB has CF 2500kN; α-S300iB has CF 3000kN; and α-S450iB has CF 4500kN. Moreover, all new models adopt a 21.5-inch-wide display.

Especially for α-S300iB and α-S450iB models, the injection unit valuation has been widened to suit several market needs. Specifically, α-S300iB accommodates large, standard or small capacity injection unit /3 types. Meanwhile, α-S450i accommodates large, standard, small or ultrasmall capacity injection unit /4 types.

New Function of ROBOSHOT

The ROBOSHOT-LINKi2 is a production and quality information management tool for a molding factory. The added new function supports maintenance and inspection activity.

The inspection items described in the ROBOSHOT maintenance manual have been registered in advance. In this way, it makes online management quickly available for regular inspections.

Users need to register maintenance work on the ROBOSHOT-LINKi2 calendar screen. Then, a warning display on a PC monitor or a tablet device will notify the inspection timing. Moreover, users can also register their own inspection items and referred manuals during maintenance work. Also, users can take inspection point as images and record them.

Specifically, the maintenance and inspection support function make online management possible from planning to implementation. Further, it can assist molding factories pursuing digital transformation.