ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ASMPT Touts Open Automation in China Event

ASMPT will present groundbreaking solutions for the integrated smart factory at the NEPCON China trade fair. Particularly, the products will range from powerful line and factory software to ASMPT’s Open Automation concept, a fully automated production line, an SMT line designed especially for the needs of the automobile sector and advanced packaging solutions. Furthermore, ASMPT will present everything needed to advance the transition to future-oriented intelligent electronics manufacturing.

The NEPCON China trade fair will run from July 19 to 21 at the Shanghai World Expo Exhibition & Convention Center. With the theme “Accelerate! OPEN AUTOMATION by ASMPT”, the company will present innovative hardware and software solutions for the integrated smart factory.

Smart Operations in Intelligent SMT Factories

At booth 1F60, visitors will gain insights into ASMPT’s comprehensive and steadily growing portfolio of coordinated software solutions. With its smart shop floor management suite WORKS and its Factory Automation software for connecting AMR fleets as well as its Critical Manufacturing MES solution, ASMPT is the only supplier that can link the worlds of hardware and software across the board.

Moreover, the company’s intelligent applications enable users to deploy staff more effectively, ensure maximum equipment availability and establish an effective and transparent material management system. At the same time, perfect their quality management in a closed-loop system.

Future-oriented and seamlessly integrated: The Open Automation line

With its Open Automation line featuring fully automated setup changeovers via autonomous mobile robots, ASMPT will demonstrate a modern, highly automated SMT line that delivers maximum production speeds and volumes. It features a new-generation DEK TQ printer with Smart Pin Support, a Process Lens HD SPI system and SIPLACE TX placement machines with a Smart Tray Unit, all of which work together without operator assists.

An IPC-Hermes-9852-compatible PCB loader and conveyor ensures fully automatic product movements. By defining standardized data formats and communication protocols, this open industry standard allows equipment from multiple manufacturers to work together and exchange board data with each other. The result: continuous production with maximum quality.

Automotive line: SMT assembly that meets the most demanding standards

Another highlight specially designed for the automobile industry this time is the combination of a DEK TQ L printing platform and a SIPLACE SX placement machine. Both systems feature numerous automation options and unique levels of precision and flexibility for demanding SMT production requirements.

Moreover, the DEK TQ L, for example, processes up to 244 circuit boards per hour that can measure up to 600 × 510 millimeters. Equipped with the OSC Package, Clinching Option and CPP Gripper, the accurate and flexible SIPLACE SX placement machine impresses with demand-oriented scalability and expanded feeding and transport options. Three innovative placement heads ensure maximum precision and reliability, particularly for industry-typical requirements such as LED centering, snap-ins and THT placements. And thanks to standardized interfaces, even third-party feeders can be seamlessly integrated into the production line.

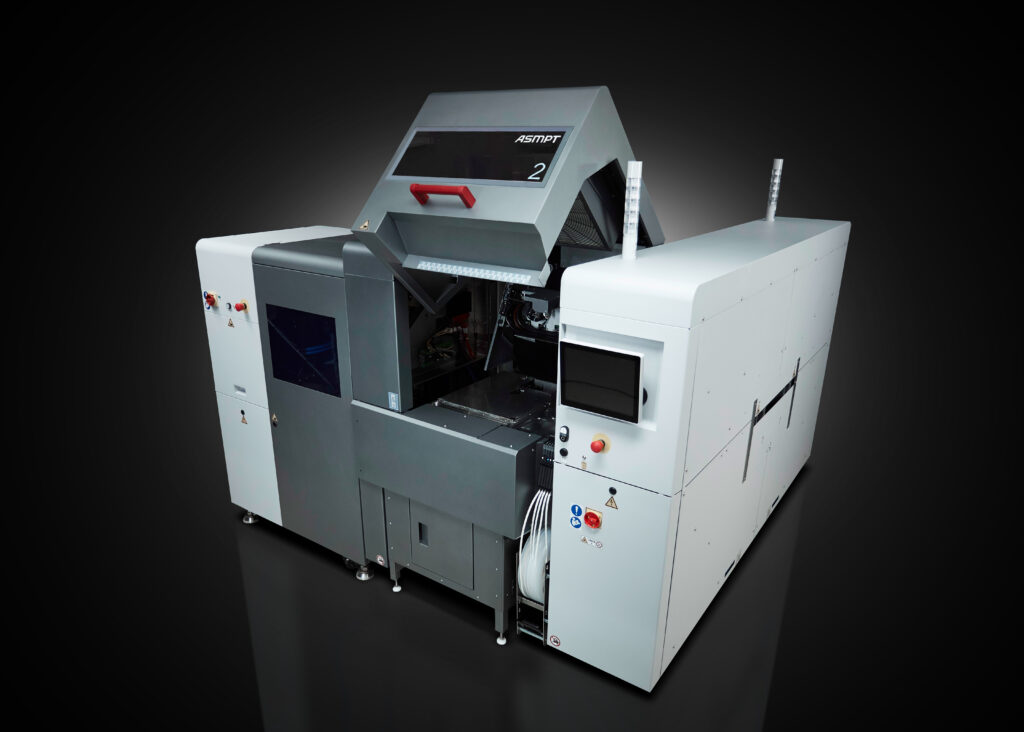

SIPLACE CA2: New dimensions in advanced packaging

With its multi-wafer system, the SIPLACE CA2 is another machine that sets new standards in terms of performance, precision, and flexibility. The innovative placement system from global market and technology leader ASMPT combines the high-speed assembly of chips taken directly off the sawed wafer with SMT placement technology. Thus, integrating the production of SiPs directly into the high-speed SMT line – a highly attractive option for electronics manufacturers in the smartphone and tablet segments.

Its changer holds up to 25 wafers and swaps them out in only 5.6 seconds. The SIPLACE CA2’s placement accuracy of up to 10 microns @ ±3 sigma is also trendsetting.

Tailor-made automation

Eric Zhao, Head of Marketing at ASMPT SMT Solutions China, said, “We will show at our booth what system integration and automation can achieve today. This does not mean, however, that a fully automated line without operators would be the best solution for every customer.”

In addition, Zhao said, “With its modular structure and maximum compatibility, our Open Automation concept allows our customers to decide for themselves at any time what they want to automate and to what extent. The best way for them to find out which solution works best for them is to talk directly with our experts at the fair.”