ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Kurabo Drives Automation of Visual Inspection System

Kurabo Industries Ltd. proposes a solution that realizes labor-saving. Particularly, automating the pre-process of inspection by combining a parts feeder to the manual series of BBMaster visual inspection system.

BBMaster employs advanced image processing technology and dedicated software to detect defects of automotive printed circuit boards (PCBs). In addition, aluminum and ceramic boards, and light-emitting diode (LED) substrates.

High-speed switching system, which takes images while switching lighting, focuses light on various angles. Thus, enabling high-accuracy detection of defects.

Reliable Inspection Process

BBMaster-1100V is a single-sided manual-setting type manual system. Featuring a compact design, it is a space-saving system suitable for prototyping and for use in the development stage although it is not as fast as a dual-sided automated inspection system in terms of inspection speed.

An operator manually carries a PCB and puts it on the stage to inspect it. Nonetheless, continuous inspection has become possible by combining the system with a material handling device that automates the work to put PCBs in and out of the inspection system.

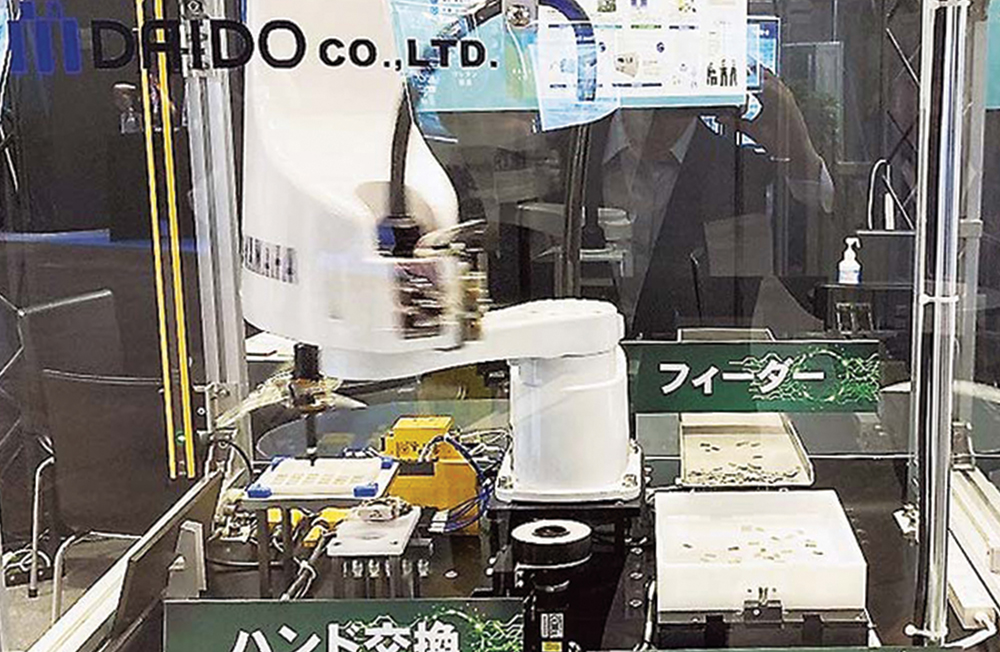

Kurabo Industries proposes the solution in combination with Daido Co., Ltd.’s SCARA robot and loader/unloader. Accordingly, the robot automatically aligns PCBs (chip substrates) to be inspected on the tray. Then, BBMaster-1100V tests PCBs in the tray at once and the robot automatically takes out the tray. BBMaster-1100V can inspect small substrates and small dies aligned on the tray at once, as well as PCBs of ordinary size.

The inspection system recognizes both sides of PCBs and components before they are aligned using a camera. After catching PCBs and components, it incorporates angle information using the camera once again before they align and carries out corrections.

High-Efficiency Inspections

According to Kurabo Industries Environmental Mechatronics Division, “Some users first establish inspection using the inspection machine, and then automates the system using the material handling devices in stages.” The system combining BBMaster-1100V and the material handling system has already been installed in PCB manufacturers. “The system receives high evaluations for the reduction of man-hour and inspection time,” notes the Environmental Mechatronics Division.

BBMaster detects various defects of PCBs in various applications, ranging from large systems for mass production to systems for development. 1100VL, the same single-sided manual setting type as 1100V, supports large-size PCBs.

Moreover, Kurabo Industries proposes dual-sided automation systems, such as 7000 and 8800, to meet needs for high-efficiency inspections. The company aims to differentiate its products from other companies’ products by promoting automation that realizes labor-saving in addition to high inspection accuracy.