ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Panasonic’s New Technology Streamlines Motion Teaching for Robots

Panasonic Holdings Corporation has developed a new technology that can teach robot motions that include contact with the surrounding environment (doors, tables, and more). Also, it developed control parameters that achieve both performance that correctly completes the taught motion and safety during contact.

As the use of industrial robots advances, technology for efficiently programming robot movements is becoming more and more important. Particularly, in environments involving contact with people and objects, movements that reduce the risk of contact while performing tasks accurately are required. However, robot control that achieves both are known to be extremely difficult. Therefore, we have developed a method to efficiently program a robot assuming it behaves flexibly like a spring. Also, we developed a novel method to learn stiffness parameters of impedance control to satisfy both task performance and safety requirements. To this end, we segmented the motions taught to robots demonstrated by humans and multi-objective Bayesian optimization.

This advanced technology has received international recognition. Moreover, the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS) 2023, a top conference for AI and robotics technology (having an acceptance rate of 43%), has accepted the technology. It will be presented at the plenary session to be held in Detroit, Michigan in the USA from October 1 to October 5, 2023.

Overview

Direct teaching, in which humans directly teach robots movements, is widely used as a method of programming robot movements because of its simplicity. However, when a robot reproduces a taught action in an environment where there is contact with objects or where people or other robots cooperate or divide labor, it becomes necessary to deal with the risk of unforeseen contact in order to avoid damage to people, objects, or the robot itself, making it difficult to utilize robots for certain tasks.

In the field of control technology for flexibly moving robots, there is impedance control*1. It mimics a virtual spring system and gives the robot flexibility like a spring. If an appropriate spring system parameter (impedance gain) is set, it is possible to reduce the risk of contact while having the instructed operation performed accurately.*2. However, with impedance control, there is generally a trade-off between safety and motion accuracy. Also, it is difficult to set an impedance gain that optimizes both at the same time.

To achieve the desired task, it is necessary to accurately perform multiple consecutive actions. For example, in the case of opening a door, the robot must 1) approach the knob, 2) turn the knob, and 3) open the door. However, optimum impedance gain differs for each operation.

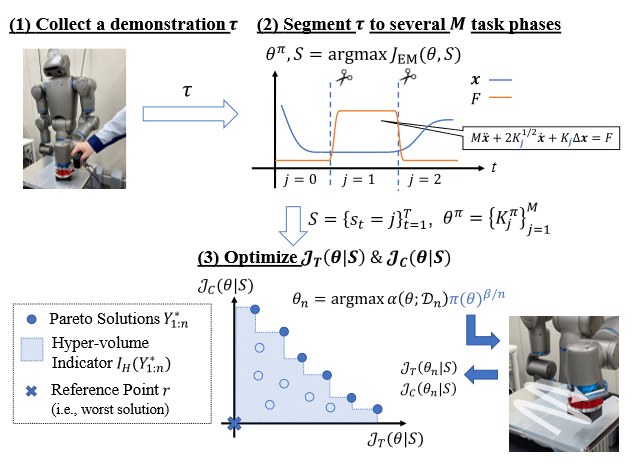

Therefore, as shown in Figure 1, we developed a method that first segments a series of motions being taught to facilitate parameter optimization. Then, it finds the optimal impedance gain for each segment using multi-objective Bayesian optimization.

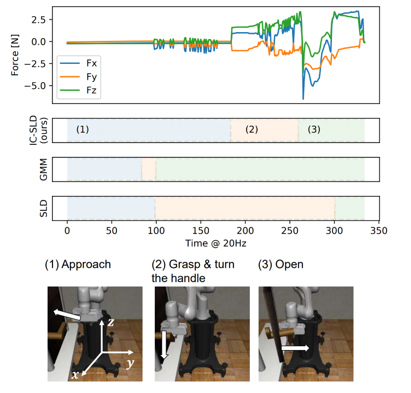

First, the newly developed task segmentation method IC-SLD (Impedance Control-aware Switching Linear Dynamics) assumes that a series of demonstrated motions are generated by multiple combinations of spring system motion equations assumed by impedance control. The series defines this as the problem of inferring the unknown impedance gain and the switching time of the equation. IC-SLD solves this problem by minimizing the error between the predicted trajectory and the actual taught trajectory. Compared with conventional methods (e.g. GMM*3 or SLD*4), IC-SLD realized segmentation suitable for optimization (Fig. 2).

Subsequently, the impedance gain is explored through Bayesian optimization*5 using prior knowledge. Since IC-SLD also outputs an estimated value of the impedance gain, using this as a solution candidate makes optimization more efficient. Bayesian optimization π-BO [Hvarfner+,ICLR2022], which is able to make use of prior knowledge is applied. Thus, optimal impedance gains that simultaneously optimize task performance (the cumulative sum of reward functions) and safety indices (the cumulative sum of stiffness parameters) are searched while repeating robot motion trials.

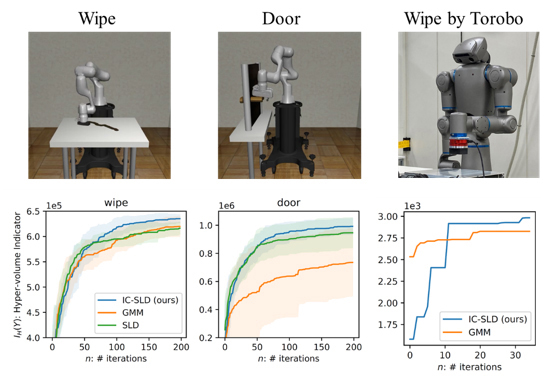

Experiments on simulated tasks and a real robot demonstrated that our method allows for learning the impedance gain in a shorter time than the conventional method (Figure 3).

Notes:

*1: Impedance control is a control method that adjusts the apparent mechanical impedance (inertia, damper, stiffness) against external forces by assuming that the robot follows a virtual spring system.

*2: As an example, in the door opening task shown in Figure 2, there is a risk of damage being done to the door as the robot positions its arm, such as the handle may be rotated excessively due to positional deviation due to control errors, or the handle may be pulled in a different direction due to the robot being misaligned with respect to the door. On the other hand, with impedance control, the flexibility of the spring can reduce the above risks.

*3: Segmentation based on clustering by GMM (Gaussian Mixture Model).

*4: SLD (Switching Linear Dynamics) Segmentation assuming that the motion being taught is generated by a combination of simple linear equations.

*5: Bayesian optimization: A method of learning the shape of an unknown function from data and trying to estimate the optimal solution for that function with as little data as possible.

Related Information:

“Learning Compliant Stiffness by Impedance Control-Aware Task Segmentation and Multi-Objective Bayesian Optimization with Priors”, to appear in IROS 2023 https://arxiv.org/abs/2307.15345

This research is a result of a collaboration between Masashi Okada, Ryo Okumura of Panasonic HD Technology Division, Mayumi Komatsu of Panasonic HD Manufacturing Innovation Division, and Professor Tadahiro Taniguchi of Ritsumeikan University/Panasonic HD Technology Division.

– IROS 2023 official website https://ieee-iros.org/

– Panasonic×AI website https://tech-ai.panasonic.com/en/

– Robotics Hub website https://tech.panasonic.com/global/robot/