ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

AI Drives Mitsubishi Electric’s Die-Sinking Electric Discharge Machine

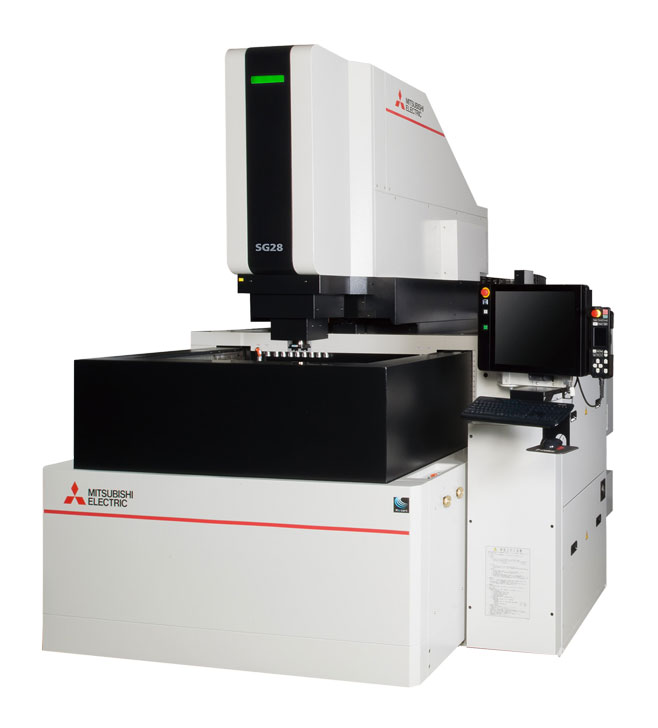

Mitsubishi Electric Corporation has recently released SG28 die-sinking electric discharge machine, a medium-sized model of the SG Series. Die-sinking electric discharge machines are used for digging a mold into a workpiece.

AI-Enabled Processing Control

The new model is equipped with the processing control function enabled by Maisart artificial intelligence (AI) technology developed by the company and is also installed with the latest mechanical structure and power supply specifications. It thus achieved optimum machining of a wide variety of workpieces, like automobile battery cases, heat sinks, and aluminum die-casting molds used for engines. Aluminum die-casting molds are used for press-fitting of melted aluminum alloys and zinc alloys into molding.

Through Maisart, optimal real-time control is performed according to the machining state. The mechanical structure has been further optimized through the improvement of the casting shape and rigidity of the head part. As a result, stable operation and high speed have been realized at the same time in machining of small, medium, and large workpieces, supporting a wide variety of applications.

By further optimizing the mechanical structure, the minimum inter-surface distance between the electrode and the table has been reduced by approximately 15mm from the EA28VM ADVANCE conventional machine, and the Z-axis movement distance has been increased by 50mm, supporting a wide variety of workpieces.

The power supply with low stray capacitance has enabled suppression of the abnormal discharge that suddenly occurs at the start of machining. The quality of the machined surface has been improved, reducing the grinding work after processing by 30 percent compared to the conventional machine.

It is equipped standard with D-CUBES numerical control device, which was originally developed by the company. The navigation displayed on a 19-inch large screen can reduce the number of operations from setup to processing.

It also supports the company’s original iQ Care Remote 4U remote service utilizing internet of things (IoT), allowing it to provide technological support for processing and realize remote monitoring of the operating status, thus greatly contributing to operation and maintenance.