ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Delta Displays Digital Manufacturing at Automation Taipei

Delta, a world-class provider of power management and industrial automation solutions, has announced its participation in the Taipei International Industrial Automation Exhibition 2023 (Automation Taipei 2023) with the theme of “Digitized Manufacturing for an Innovative Future”.

At the show, Delta focuses on “Digitized Manufacturing Solutions” as well as the newly developed “Digital Twin for Smart Equipment Implementation”. Additionally, Delta is exhibiting Virtual Machine Development Platform DIATwin and Digital Twin Machine Platform RTM/iRTM. It also places great emphasis on the two pillar industries, electronics and semiconductors. Accordingly, Delta displays a smart integration platform that facilitates the interconnection of Operation Technology, Info Technology, and Edge layers.

Andy Liu, general manager of Delta’s Industrial Automation Business Group (IABG), remarked that the post-pandemic economic recovery has been a big challenge for manufacturers. Since labor shortages are hampering the supply chain, decentralized manufacturing and worldwide business expansion are rising trends that greatly facilitate smart manufacturing.

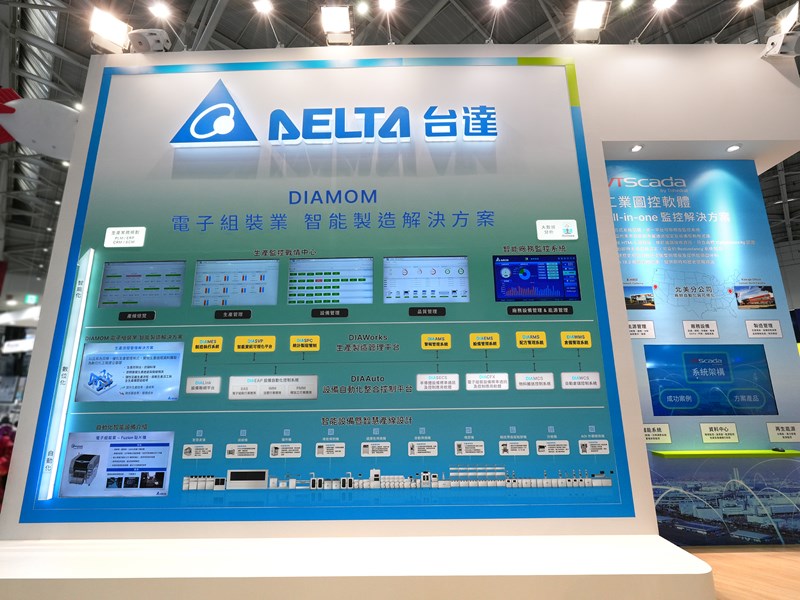

He said Delta has been deeply rooted in the industrial automation field for nearly three decades. Drawing upon its extensive experience in the electronics manufacturing sector, Delta presents the Smart Manufacturing Solutions for the Electronics Assembly Industry DIAMOM, which seamlessly integrates in-house developed automated equipment, machine networking, Manufacturing Execution System (MES), and a visualized management platform to monitor production progress, product quality, equipment real-time status, warehouse and logistics, and more. By merging Digital Twin and cyber-physical systems into production, Delta assists manufacturers in fulfilling smart manufacturing vision.

With the topic of Digital Twin for Smart Equipment Implementation, Delta has just introduced the Virtual Machine Development Platform DIATwin and Digital Twin Machine Platform RTM/iRTM. The platforms allow users to add production information into ready-to-use models, validate the sequence of operations, and generate optimal process parameters. The cyber-physical architecture reduces innovation design issues and development cost while building a physical environment. It also facilitates data gathering abilities in smart systems to continuously optimize production processes. In addition, Delta is focusing on precision processing demand in the electronics assembly. It debuts all-in-one solutions AC Motor Winding Machine Solution and PCB Loader & Unloader Machine Solution, which greatly simplify the implementation process to save time and effort.

In the Process Automation Solutions exhibition area, Delta is responding to the increased awareness of industrial carbon emissions in HVAC and fluid control applications. Accordingly, it presents Solutions for the Fluid Industry. Solutions include key components such as maglev systems, drives, high-efficiency motors, and power quality to avoid bearing friction loss when the fluid machine transfers high rotating speed to flow and pressure, achieving high speed, high efficiency, and energy saving and helping the fluid industry meet Net Zero Emissions goals. Also, Delta is demonstrating the SCADA System VTScada that has been successfully integrated at North America sites. The centralized monitoring software can control multiple systems from each plant and office; thus optimizing management efficiency through visualized and insightful data.

During the exhibition, Delta is also displaying a Smart Automation Products section. It showcases the 3D ToF Smart Camera DMV-T, which provides the capability of high-speed 3D data collection and objection detection. Particularly, it suits AGVs and shoe manufacturing. At Delta’s booth, visitors can see demos of an automated adhesive spraying solution that integrates ToF camera and Virtual Machine Development Platform DIATwin to simulate the adhesive spraying process. The camera automatically detects the shoe sole position, while the SCARA robot begins conducting adhesive dispensing. The solution not only helps customers accelerate the development and implementation process but also greatly enhances production efficiency.

In addition, the newly debuted Compact Multi-Drive MX300 features a multi-axis modular structure that enables flexible configuration of rectifier and inverter modules for optimal space, quick installation, simple commissioning, and easy networking.

Last but not least, the M∞Vair Series Wireless Charging System employs WiTricity®-licensed magnetic induction wireless power transmission technology. It delivers contactless high-efficiency charging capabilities to unmanned electric industrial vehicles like AGVs and e-forklifts. Specifically, it offers an output power ranging from 1 to 30kW, while sparing connector wear and maintenance costs.

During Automation Taipei 2023, Delta will arrange booth tour sessions and various seminars. The seminars will cover the topics of HMI IIoT, High-Speed Fluid Machinery Solution, Compact Multi-Drive, IoT-Based Fundamentals, and others. Delta welcomes press and visitors from different fields to come to its booth at Automation Taipei 2023 (booth M420, 4F, Hall 1, Nangang Exhibition Center) to learn more about digital upgrades and ways to achieve a smart manufacturing future.