ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yokogawa Bares New Upgrade of OpreX Data Model Broker

Yokogawa Electric Corporation has released of Design Diagram Converter, a new OpreXTM Data Model Broker component. OpreX Data Model Broker, a product in the OpreX Connected Intelligence lineup, is a data transformation platform that makes use of the ontology AI technique*. Particularly, in converting and verifying data scattered across various systems.

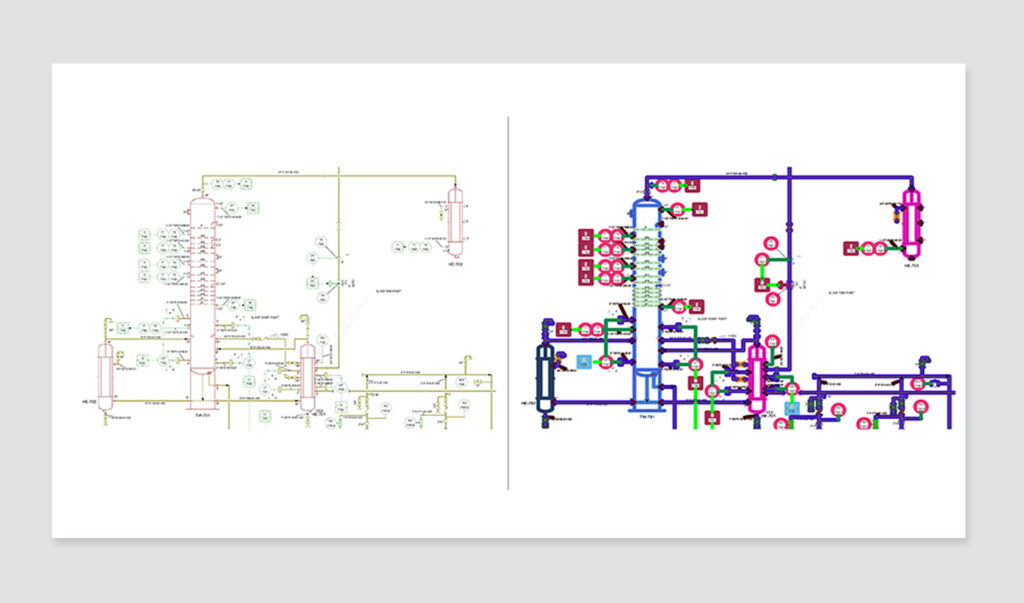

The new Design Diagram Converter component is able to read piping and instrumentation diagrams (P&IDs) created with 2D CAD software. In addition, it can automatically generate intelligent P&IDs and instrument lists processed by computers. With the automation of plant engineering work that previously had to be done manually, Yokogawa is supporting digital transformation in plant engineering.

Development Background

P&IDs play an essential role not only in design and construction, but also in the operation, maintenance, and modification of plants that process oil, chemicals, and other materials. P&IDs are created by process designers for use by the personnel tasked with implementing plant instrumentation, piping, and machinery. However, as these diagrams are intended primarily for ease of viewing, they are not optimized for computer processing, which is necessary for frequent information exchange. In such cases, it is necessary to have a specialist manually extract and process the data from these P&ID drawings, and this is time-consuming and presents quality issues.

To address these issues, Yokogawa has developed the Design Diagram Converter. With high accuracy, this software can read P&IDs created with 2D CAD software, convert them to P&IDs compliant with international standard file format, and automatically generate an instrumentation list. By automating a task that previously had to be done manually, the workload is significantly decreased, quality is assured through the reduction of human error, and the promotion of digitalizing plant engineering is achieved.

Main Features

- Automatically generates an instrumentation list by analyzing P&ID information

The original instrumentation list can be automatically generated by loading 2D CAD P&ID files into the Design Diagram Converter software.

Furthermore, for the analysis of drawings, pattern-matching techniques are necessary to extract information. In addition, the patterns can be tuned using the target drawings.

As detection accuracy can be easily adjusted, this makes it easier to start related tasks. This program is able to reduce total labor time by approximately 60%. Previously, the process requires manual extraction of data.

- Automatically generates XML documents that are compliant with international P&ID standards

With the Design Diagram Converter, information read can be exported in the XML document format, which complies with the ISO15926 international standard. The XML documents can be used on other systems and in applications that support the same format. Thus, making it easy to use design information from an existing plant asset.

* Ontology is one of the approaches in AI technology. It is a concept or mechanism for defining the meaning of information and aims to make computers mimic how humans understand the meaning of information.