ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Panasonic Lineup Boosts Automation in IC Production

The smaller the chips, the bigger the impact machines will have. Consequently, Panasonic Industry offers a complete lineup of components and solutions that take technology to the next level.

Moreover, the company said its end-to-end lineup complements applications that keep ahead in the semiconductor industry.

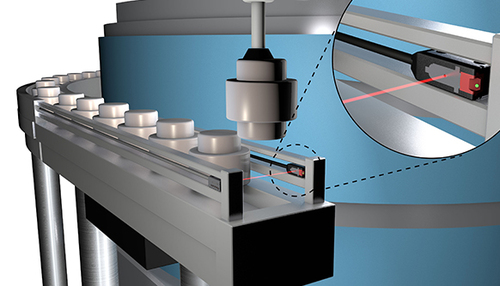

Sensors for Detection, Positioning

Detection and positioning of wafers require accurate and reliable sensor technology. Furthermore, high temperatures obviously play a role, and so does the specific handling required.

Panasonic Industry portfolio not only offers key electronic components, devices, modules, and software. Moreover, it offers complete solutions as well for production lines in a wide variety of industries.

Panasonic Industry‘s comprehensive know-how along the entire value chain, combined with a corporate culture geared to customer needs, enables it to offer customer-specific solutions that extend beyond the products.

Panasonic Industry offers comprehensive sensors for factory automation. Particularly with distance, pressure, and fiber sensors as well as inductive sensors. Among them are photoelectric sensors, which have various sensing ranges available as thru-beam, retro-, and diffuse reflective types. Moreover, the company also offers measurement sensors and IO-link sensors, which can be integrated into every network.

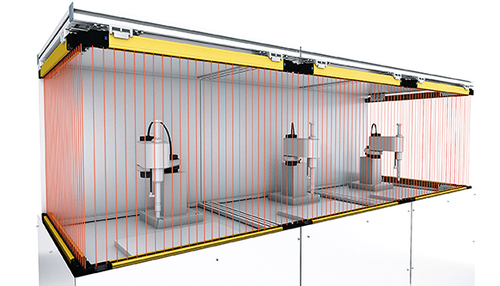

The company also offers a complete lineup of safety light curtains and safety sensors to enable safety on production floors. Particularly, products such as safety light curtains and safety sensors can provide safety precautions, such as in an etching process line.

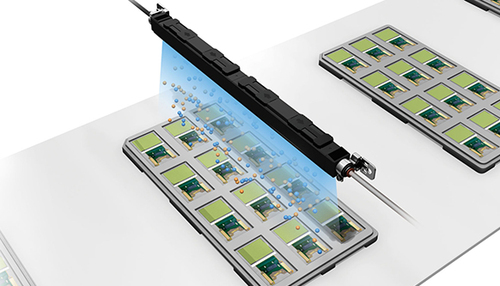

Removing Static Charges With Ionizers

There are many production processes where electrostatic charges disturb smooth operation. To eliminate static, ionizers are used. For example, in the semiconductor industry, the components are extremely sensitive and are susceptible to damage by high electric static charges.

Another example is the printing industry. Here, friction between the rollers and the paper generates static. The static makes the paper cling and not move correctly through the printing machine.

Manufacturers can also protect the production process from static charges. Particularly, those caused by removing dicing tape, stacking IC trays, or loading and unloading wafers.

Panasonic Industry’s ionizers provide a clean and neutral airflow. In addition, they are also resistant to high temperatures of up to 200 degrees Celsius and can operate without being powered by compressed air.