ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Alliance Highlights 3D Technology in Additive Manufacturing

The Kansai Bureau of Economy, Trade and Industry (METI-Kansai) started in January 2019 the Kansai-3D Practical Application Project in partnership with the 3D Manufacturing Promotion Association. The project has recently commenced three-dimensional (3D) Design for Additive Manufacturing (DfAM), which promotes additive manufacturing (AM) through 3D laminating fabrication technology.

The development of DfAM is necessary by selecting parts that create added value to additive manufacturing, the design unique to the 3D laminating fabrication, the simulation of DfAM, among other factors. The project will also support the development of DfAM and promote the digital transformation of manufacturing.

Importance of DfAM

This year, the project will introduce DfAM with the latest tools for three model companies selected that support the project and aim for the expansion of DfAM in all supporting companies. The model companies are Osaka Yakin Kogyo Co., Ltd. (metallurgy), Nakakita Seisakusho Co., Ltd. (casting), and Yamamoto Metal Technos Co., Ltd. (cutting). All are working mass production employing additive manufacturing.

The project will provide necessary assistance to 700 companies according to the level of each company. It will introduce design consulting services for DfAM, 3D-CAD software, and AM with various features, and hold meetings for individual consultation. It will create opportunities to experience the importance of DfAM, by providing a trial introductory training program to companies interested in DfAM.

The project will also hold seminars and events to let members know about various technologies including materials and heat treatment necessary for the practical use of the 3D design. At the end of the year, it plans to hold seminars introducing the technologies related to 3D printing including proper metal materials and heat treatment.

In the first and second years, the project has selected model companies that actively explore the possibility of utilizing and introducing new 3D tools for the practical application of 3D, making the best use of the subsidies. The project has built a business model by supporting verification of processes required for introducing 3D manufacturing. From 2021, the project will include support for DfAM.

Value Added Features

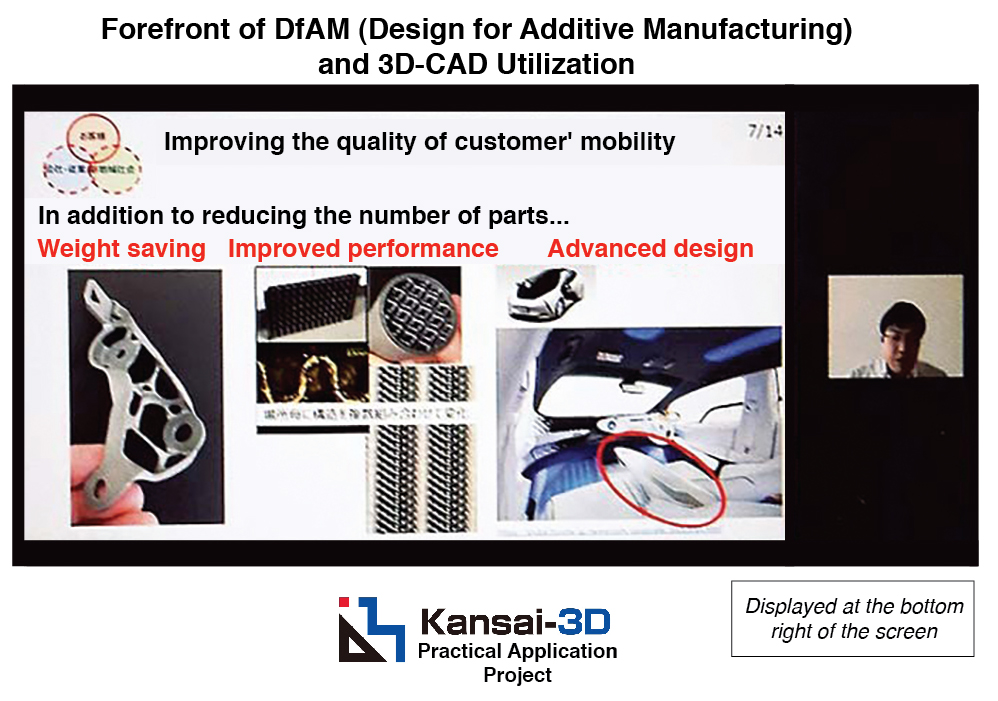

METI-Kansai and 3D Manufacturing Promotion Association recently co-sponsored “Forefront of DfAM and 3D-CAD Utilization”, a virtual seminar, attended by 400 participants.

At the event, Hiroyoshi Kuroki, Director, Next Generation Industry and Information Policy Division, Economic Policy Department, METI-Kansai, said, “Manufacturing by AM (additive manufacturing) cannot be achieved by simply converting 2D design to 3D and by introducing a 3D printer. Which of many parts can acquire significant added value with AM? It is important to analyze and simulate the materials, equipment, and post-processes, and then to select the parts.”

Furthermore, Kuroki stressed the importance of DfAM, saying, “It is important to utilize the added value of AM for the purpose of adding new functions to the product, rather than just reviewing the design based on conventional one. That is the essence of DfAM. Construction of a new manufacturing process by the simulation using 3D-CAD digital data will lead to the digital transformation (DX) of manufacturing in a true sense.”