ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

JUKI Smart Solutions: Transformation and Business Growth Through Automation

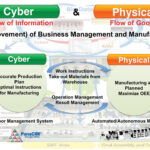

JUKI Corporation will offer at NEPCON China 2021 four solutions that will accelerate innovation at customers’ facilities and growth of their businesses through JUKI’s automation solutions. These solutions will evolve around the theme “JUKI Smart Solutions – Factory Transformation and Business Growth Through Automation”.

High-Speed, High-Quality Line Solution

The diversification of printed circuit boards has been accelerating to accommodate fifth-generation (5G) communications-related devices, wearable devices, and light-emitting diode (LED) displays, and the mounting process is now shifting from variable-volume, variable-mix production to high-mix, low-volume production. JUKI proposes the latest line solutions targeting the mounting process.

JUKI proposes a high-speed, high-quality mounting line by combining the RX-7R high-speed compact chip mounter and RS-1R ultimate all-in-one mounter, which features both general versatility and high speed, and the RV-2-3DH high-speed, high-precision three-dimensional (3D) inspection machine.

JUKI will also introduce a leading-edge high-speed, high quality line solution that achieves high throughput in the entire line by connecting various systems and functions, including feedback and feedforward function to convey information obtained in the preceding process to succeeding machines; trace monitor, which enables real-time monitoring of operation conditions of equipment remotely; and visualization function of production progress and equipment operation conditions.

Post-Process Automation Solution

JUKI has achieved automation of the component insertion process of many leading companies through the JM Series multitask platform.

At NEPCON China 2021, JUKI will premiere the new JM Series, which is optimal for high-mix, low-volume production, inheriting high technical and support capabilities the company has nurtured in the production of the JM Series. When integrated with the newly developed multi bulk feeder, which supports high-speed supply of randomly stacked parts, it significantly reduces setup changeover time and achieves dramatically high productivity.

Meanwhile, the MR-01 innovative robot system can handle two tasks — the insertion and screw tightening of large connector components, which normally requires manpower, simultaneously using upper and lower robots. It achieves high area productivity and improved return on investment (ROI).

This platform will further expand areas it supports in accordance with customers’ requirements toward achieving automation of various assembly processes beyond insertion and screw tightening works.

Automation Solution for Electronic Components Management

JUKI proposes an automation solution for innovative electronic components management using robot and internet of things (IoT), targeting higher efficiency and optimum warehouse management of components and products in various industries.

At NEPCON China 2021, JUKI will premiere the ISM3900 storage capacity expansion module, which enables the storage of large capacities of components in accordance with the capacity of components on the production site, as an expansion unit of the ISM Series.

Furthermore, aside from the automated guided vehicle (AGV) system, which automatically transfers components to the production site in a timely manner, JUKI will propose an innovative solution for the entire component management process, including incoming materials station, which improves efficiency of accepting reel components, reduces work errors, and achieves traceability through the issuance of individual barcodes and individual management of tape reels.

This is an innovative solution that is useful for customers of all industries and businesses with issues in the component supply process.

Factory Support Solution

JUKI will promote its latest factory support solution, including more specific proposal of remote support using leading-edge technologies, such as virtual reality (VR) and augmented reality (AR), as well as its efforts to provide online web seminars and web trainings.

The company will introduce various support systems that enhance productivity, including remote support to enable remote maintenance by grasping the production status, and line and equipment conditions in real time from remote factories and management rooms, as well as web seminars and trainings from remote locations.

JUKI will also propose various solutions that support customers’ factory innovations to improve the efficiency of production site management, borderless components supply support, and factory support.

JUKI will expand solutions in various fields and continue to evolve to provide innovative products and systems that improve production efficiency, targeting to become “A Solution Partner” that can contribute to factory innovation and the business growth of customers around the world.