ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New LG Chem Material Delays Battery Thermal Runaway

LG Chem, together with LX Hausys, has developed a material delaying battery thermal runaway and can withstand a flame at 1,500°C for over 20 minutes. The Special Flame Retardant Continuous Fiber Thermoplastic is characterized by its capacity to withstand strong flames and high pressure for more than 14 times longer than existing thermoplastics.

Thermal runaway is the main cause of electric vehicle battery fires. Mainly, it is a phenomenon where heat is generated in a battery cell as it is subject to stress from various causes. Thermal runaway phenomenon is one of the factors that delay the popularization of electric vehicles. Also, it has been considered a pain point for electric vehicle and battery customers. LG Chem and LX Hausys resolved the heat and pressure associated with thermal runaway through development of the Special Flame-Retardant CFT. Specifically, this was difficult to withstand with existing plastics.

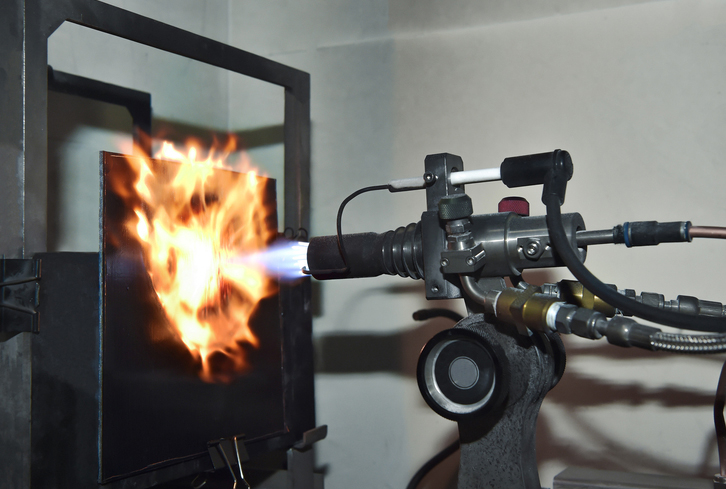

Internal Test

LG Chem conducted an internal test (torch test) subjecting the 1.6mm thin Special Flame-Retardant CFT to temperatures exceeding 1,500°C and to pressure. As a result, the material did not melt, run down, or develop any holes even after 20 minutes. This is the industry’s highest level of flame blocking performance.

Specifically, the Special Flame-Retardant CFT incorporates LG Chem’s super flame barrier material technology. Additionally, it implements LX Hausys’ Continuous Fiber Thermoplastics (CFT) manufacturing technology. The super flame barrier material developed by LG Chem last year had the capacity to withstand flames at temperatures exceeding 1,000°C for over 10 minutes, the longest at the time. Eventually, LX Hausys improved the performance of LG Chem’s material by manufacturing technique of layering thermoplastic in the form of tape to the material.

The Special Flame-Retardant CFT is solid and has low deformation under force (high rigidity). Therefore it can be used in the top and bottom covers of large battery packs among electric vehicle battery components. It is expected that it will effectively delay the spread of flames in the event of an electric vehicle fire. Thus, it can help secure the time required for driver evacuation and fire suppression.

Last year, LG Chem completed the development of super flame barrier materials and established a mass production system. Super flame barrier materials, capable of precise molding, are primarily used in battery modules. As the special flame-retardant CFT developed this year is used for the large battery pack cover that encases the module, using both materials together can provide a double barrier against the spread of flames.

Tom Shin, Head of Department, Marketing Department, Engineering Materials said, “We have been working closely with LX Hausys since we developed and announced a super flame barrier material last year. We are proud to have a total solution lineup* for electric vehicle thermal runaway.” and added, “We will continue research and development to make the daily lives of electric vehicle drivers safer while addressing customer pain points.”

*Super flame barrier, Glassmat (Glass fabric insert molded thermoplastics), CFT (Continuous fiber composite (UD-tape))