ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

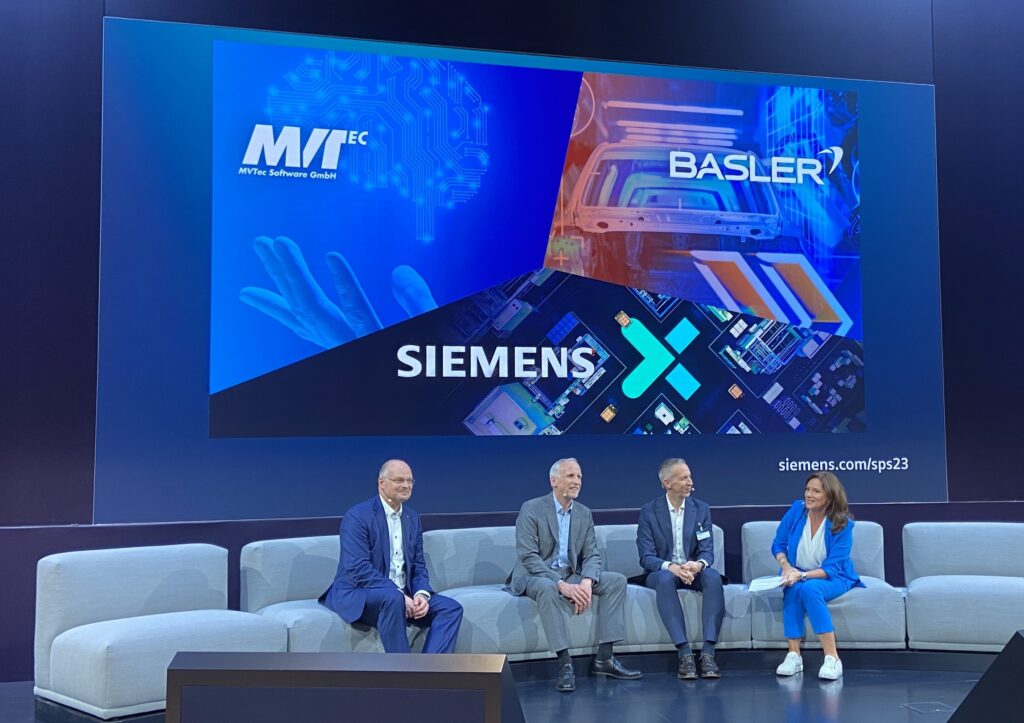

Siemens Seals New Allies to Boost Machine Vision in FA

Two industry leaders in machine vision and industrial image processing independently join forces with Siemens. As a result, customers can integrate machine vision applications directly into their existing automation technology. By combining their respective strengths, portfolios, and experience, it will be possible to offer plug-and-play machine vision solutions. Thus, aligning the portfolio of automation and machine vision components consisting of hardware and software.

Machine vision technology significantly improves quality control in production, making it less error-prone, time-consuming, and costly. Currently, integrating cameras into automation is a cumbersome process. Thus, requiring a high level of specific expertise to match compatible components.

Moreover, it is expensive and oftentimes, standalone “islands” implementation has been the norm. For example, using dedicated industrial PCs. Combining Siemens’ expertise in industrial automation and digitalization with the offerings of machine vision experts Basler and MVTec reduces complexity for customers. At the same time, lowers the barrier significantly. Hence, enabling customers to easily integrate machine vision solutions into their machines and systems.

“Together with our new partners in the open Siemens Xcelerator ecosystem, we’re integrating machine vision into automation. This helps with many tasks, for example when it comes to difficult quality control or to reduce errors and thus defects in industrial production, or to react to the shortage of skilled workers. In doing so, we are taking an important step towards an adaptable, sustainable production and increasingly autonomous production processes,” says Rainer Brehm, CEO Factory Automation at Siemens.

Standardizing visual inspection infrastructure with Basler

Basler AG is a leading full-line provider of advanced computer vision products such as cameras, lenses, and lighting. Siemens and Basler have agreed on an interface that makes it possible to use the Basler hardware portfolio throughout the Siemens automation portfolio. Moreover, it eliminates the typical challenges and errors that arise when connecting a camera to the automation system.

The first product launch to address this is the “Basler Vision Connector” app. The app makes it easier to connect the Basler camera portfolio to Siemens Industrial Edge. The same interface used for the Edge app will also be used for a forthcoming S7-1500 technology module, which will allow Basler cameras to connect directly to the Simatic S7-1500 system on a broader scale. Thus, supporting conventional as well as AI-based machine vision applications.

This newly defined standardized infrastructure for visual inspection offers an end-to-end solution for customers who already have an AI model. However, are not yet able to use it in an industrial environment.

Nonetheless, Dr. Dietmar Ley, CEO of Basler AG, said, “Our collaboration will enable us to offer customers pre-tested application scenarios and aligned product portfolio options to choose from, as well as to develop solutions that can help them significantly reduce their time-to-market.”

End-to-end anomaly detection for visual inspection with MVTec

MVTec Software GmbH is a leading manufacturer of hardware-independent software for machine vision. The company is bringing the first application for surface inspection and optical quality control to Siemens Industrial Edge.

The app called “Anomaly Detection for Visual Inspection” helps customers use AI to detect both structural and logical defects on objects and thus improve the quality of components. It is easy to learn, test, and use because it does not require programming or an in-depth knowledge of machine vision. By using the app, customers do not need third-party-stand-alone solutions. “By combining the Siemens Industrial Edge Ecosystem and MVTec’s machine vision expertise, customers can easily leverage the power of AI-driven software apps for visual inspection,” says Dr. Olaf Munkelt, Managing Director of MVTec.