ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Epson Completes Construction of New Akita Factory

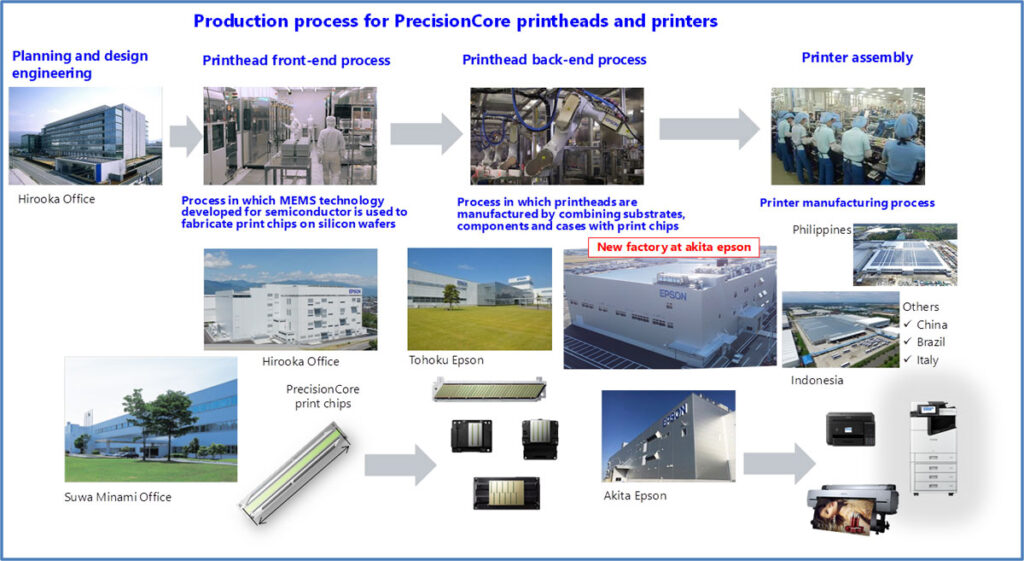

The construction of a new factory at Akita Epson Corporation, a Group company of Seiko Epson Corporation has now been completed. Most importantly, the facility, built with an investment of ¥3.5 billion, will approximately triple Akita Epson’s future printhead production capacity.

Epson’s printing solutions business provides products and services based on original Micro Piezo inkjet technology. Particularly, the company caters to customers in the office, home, commercial, and industrial markets.

Earlier, the company started the construction of the new factory in November 2022.

Complements Market Demand

Global demand for inkjet printers will likely to continue growing. In the office and home inkjet printer markets, strong demand has been complemented by robust demand for high-capacity ink tank printers. Particularly, not only in emerging markets but also in North America and other developed economies.

Likewise, demand for commercial and industrial inkjet printers is increasing along with a technology shift from analog to digital. Specifically, in sectors where the printing media is not paper, such as digital textile printing.

Moreover, many commercial and industrial inkjet printers use PrecisionCore MicroTFP printheads*. This can be flexibly adapted for different applications by assembling MicroTFP print chips in various combinations.

Currently, about 20% of Epson’s inkjet printers come equipped with PrecisionCore printheads. This percentage will increase further. This is because commercial and industrial printers and high-speed linehead inkjet multifunction printers use a larger number of print chips per unit.

Increased Production Efficiency

Epson designed the new Akita Epson factory to meet the need to increase the production and assembly of printheads, the core component of inkjet printers. That is, to keep pace with the increased production of MicroTFP print chips. The company made possible the investment in the front-end process at Epson’s Hirooka Office, in Shiojiri, Nagano Prefecture.

The factory also can provide space for future expansion of the facility. That is, to strengthen the product lineup and expand printhead sales to third parties. In addition, meet the growing demand for inkjet printers equipped with PrecisionCore MicroTFP printheads.

The new factory is adjacent to the existing printhead factory and has enabled greater efficiency from components production through to assembly.

Moreover, the production equipment and processes have been arranged to further increase human productivity and space productivity. Specifically, the new facility has a newly designed, optimal layout. That is, Epson robots and other equipment will be arranged on islands. By using this island design, Epson aims to increase production efficiency by 30% on a high-throughput production line.

As a production site with premier technological capabilities, Akita Epson closely collaborates with Epson’s research and development centers in Japan. Moreover, it shares the advanced production technology and know-how it gains through the production of core devices with Epson’s overseas production sites to improve the Epson Group’s overall manufacturing capabilities.

Note:

* PrecisionCore MicroTFP printheads are critical components that determine the image quality and speed of an inkjet printer. Equipped with an array of individually controlled nozzles, they can eject 50,000 tiny ink droplets per second. Particularly, they have droplet sizes as small as several picoliters (a picoliter is one trillionth of a liter).