ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Makers Opt for Low-Ag Solders Amid Rise in Ag Prices

The continuous rise of silver (Ag) prices is making an impact on the solder industry. Thus, solder manufacturers are advancing the development of low-Ag products to reduce costs. At the same time, they develop in demand solder products to meet market needs.

Previously, tin (Sn)-copper (Cu)-lead (Pb)-based solders, a type of solder alloy, was the mainstream. However, considering the effects of Pb on the environment, adding products with Ag in place of Pb to Sn-Cu as base materials are widely used nowadays.

Ag as Eco-Friendly Option

In 2000, the Japan Electronics and Information Technology Industries Association (JEITA) recommended Sn-3Ag-0.5Cu (SAC305) as standard in Japan. SAC305 employs Sn and Cu as base materials and includes 3 percent Ag (mass ratio) or 3Ag. SAC305 is widely adopted in home electric appliances and audio-video (A/V) equipment.

Ag accounts for about half the cost of solders. According to historical prices reported by Tanaka Kikinzoku Kogyo K.K., the price of 1g of Ag, which was at the 20 yen level around 2000 rose to the 50 yen level in 2010, and continued to increase gradually. Prices turned downward shortly between 2019 and Apr. 2020, but turned upward again after that. Since the beginning of this year, prices have been hovering at 90 to 100 yen.

Reducing Ag Content

Pressed by cost reduction from rising Ag prices, solder makers accelerate the development of low-Ag and Ag-free products by decreasing the content of Ag from 3 percent. They are also developing new solder materials to suppress the reduction of connection strength resulting from lower Ag content. They add new materials, such as indium (In), cobalt (Co), antimony (Sb) and germanium (Ge), for use in electric vehicles (EV) substrates that require greater strength.

Focuses on Power Devices

KOKI Co., Ltd. strengthens solder products for power devices, while expanding its lineup of low-Ag products. KOKI has developed a solder paste as a connection technology to replace solder preform of power devices. It accommodates formic acid reduction vacuum reflow process. It was developed jointly with Origin Electric Co., Ltd., a manufacturer of vacuum reflow soldering systems. Inquiries for the solder paste has been increasing mainly from companies in Europe.

By application, KOKI has released the S3X58-HF1100 high-functional general-purpose halogen-free solder paste for surface-mount technology (SMT). Leveraging powerful wetting and flux coagulation techniques, it solved various challenges in soldering using solder paste, including wetting, ICT testing, flux splattering, voiding, printing, tackiness, electrical reliability, and halogen free.

Flux-Cored Solders

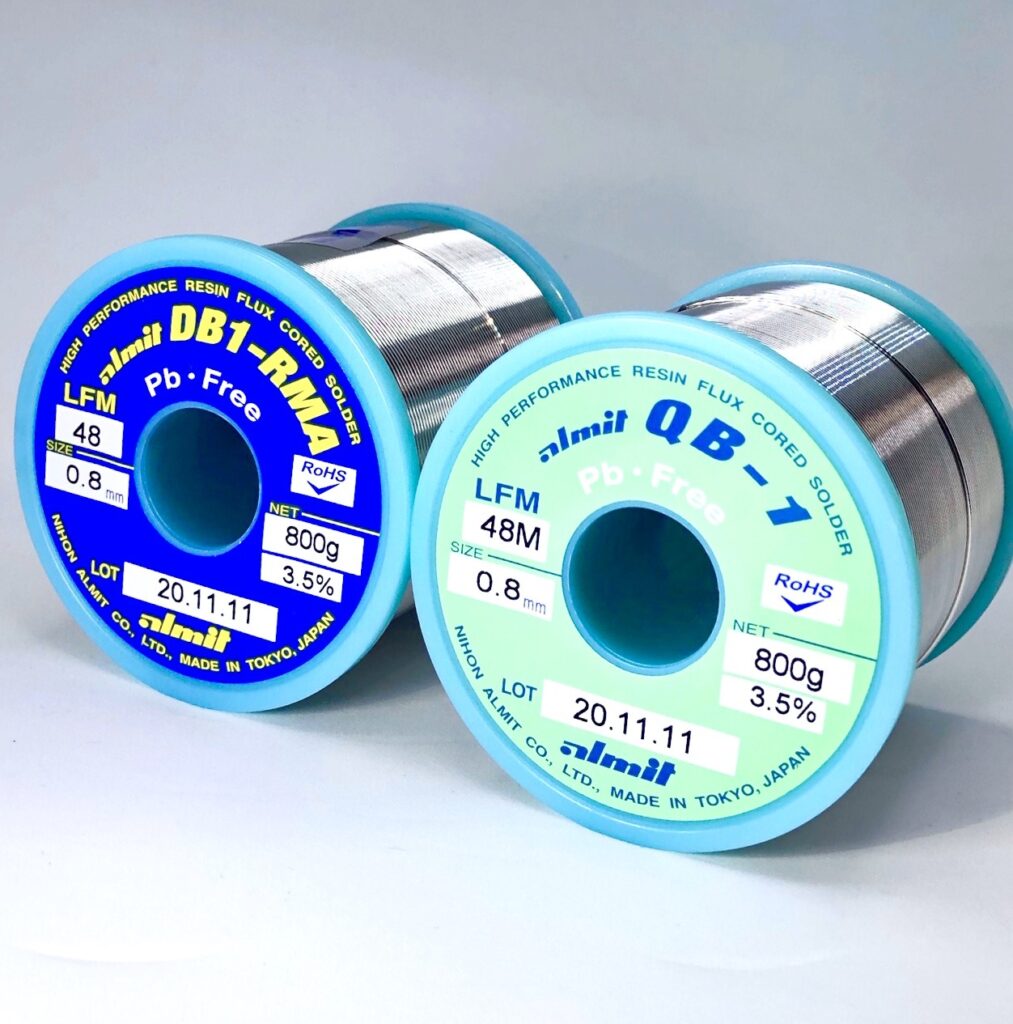

Nihon Almit Co., Ltd. has developed dual boost, a new technology to promote wetting of solder in two stages by combining two types of active ingredients: quick-acting active ingredient and slow-acting active ingredient, in the flux. The company brought to market the DB1-RMA+LFM-48 (flux name + alloy name) flux-cored solder wire as a new product using this technology. The new technology has achieved both initial wetting of through holes and solderability in through holes.

Nihon Almit has also developed quick boost, a new technology to achieve fast-acting property to instantly bring the active force in the flux to its peak. The company has commercialized QB-1+LFM-48M (flux name + alloy name) flux-cored solder, which adopts the technology.

Ag-Free Solder

Nihon Superior Co., Ltd. has brought to market SN100C Ag-free solder. The company offers in its lineup various Ag-free solders, including SN100CV, a new alloy with no Ag content and provides high strength. It is based on SN100C with added improvements. SN100C P900 D2, a lead-free solder paste exclusively for formic acid reduction reflow, is designed for the power devices field. It has achieved low void property and ultralow residue property with no flux residue left after mounting.