ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japan Unix Propels Automation With New Systems

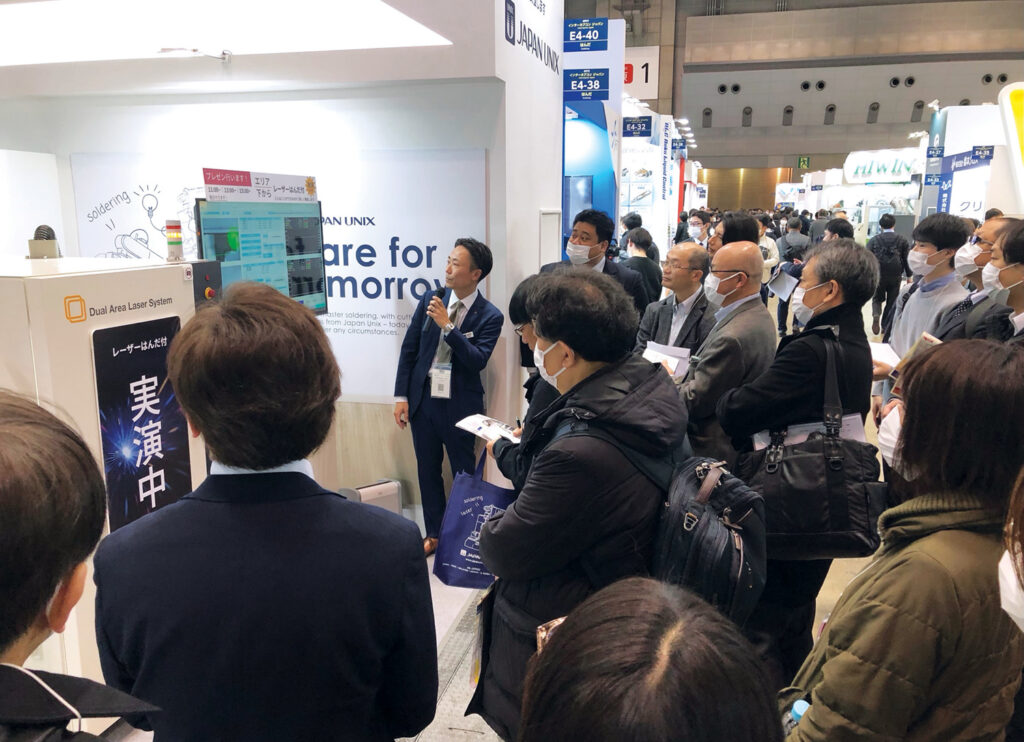

Japan Unix Co., Ltd. exhibited at the recent NEPCON Japan 2024, which took place at Tokyo Big Sight in Tokyo, Japan. Particularly, the company introduced new soldering robot technology, new products, and a variety of soldering solutions.

The company is expanding its global business as part of soldering specialists with soldering robots as its mainstay.

The world’s exit from the COVID-19 pandemic in 2023 also marked the resumption of face-to-face trade events. In fact, Japan Unix participated in SMT-related exhibitions outside of Japan. Namely, these exhibitions included PC APEX EXPO in San Diego, United States; NEPCON in Southeast Asia; and Productronica in Munich, Germany.

Supplements Increasing Need for Automation

At NEPCON Japan, the company exhibited the Dual Area Soldering System, which enables laser soldering from the underside. In addition, it also showed the UNIX-DF Series desktop soldering robot and the FR Series horizontal multiple-joint soldering robot.

Kentaro Kono, Managing Director of the company, said, “Automation is attracting more and more attention due to the shortage of labor in the manufacturing industry. In addition, as cars become more sophisticated, there is an increasing number of companies that now venture into the assembly of electronic devices. Thus, exhibiting at the NEPCON has been a good opportunity for us to make face-to-face proposals directly to industry players in the ecosystem.”

The dual-area soldering system employed the company’s proprietary new area laser technology. Particularly, it enables simultaneous soldering of two soldering points within a 2mm square, as well as laser irradiation from both the top and bottom surfaces.

Especially, the ability to laser solder from the underside eliminates the need to flip the board in the transfer line. Hence, requiring no jig. Compared to reflow ovens, the UNIX-DF series saves space in terms of equipment footprint and contributes to carbon neutrality due to its low CO₂ emissions.

The UNIX-DF series is capable of connecting to the factory network. Thus, the company’s unique soldering robot management software, Soldering Manager, enables real-time visualization and automation.

The horizontally articulated FR series of in-line soldering robots is a new generation of soldering robots. Specifically, they suit fully automated production lines with enhanced communication network functions for the IoT era.

Realizing a positive response

In addition, Kono said, “The products on display comprised of new technologies and new products that convey our strengths. Particularly, in the area of lasers, laser soldering, and a new type of controller. At the booth, we highlighted soldering with demonstrations of the area laser and laser from below. These gathered the attention of visitors.”

Furthermore, Kono said, “We realized that the soldering robots are easy to use and manage. Thus, we are getting a good response to the growing demand by proposing ways to improve productivity.”