ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

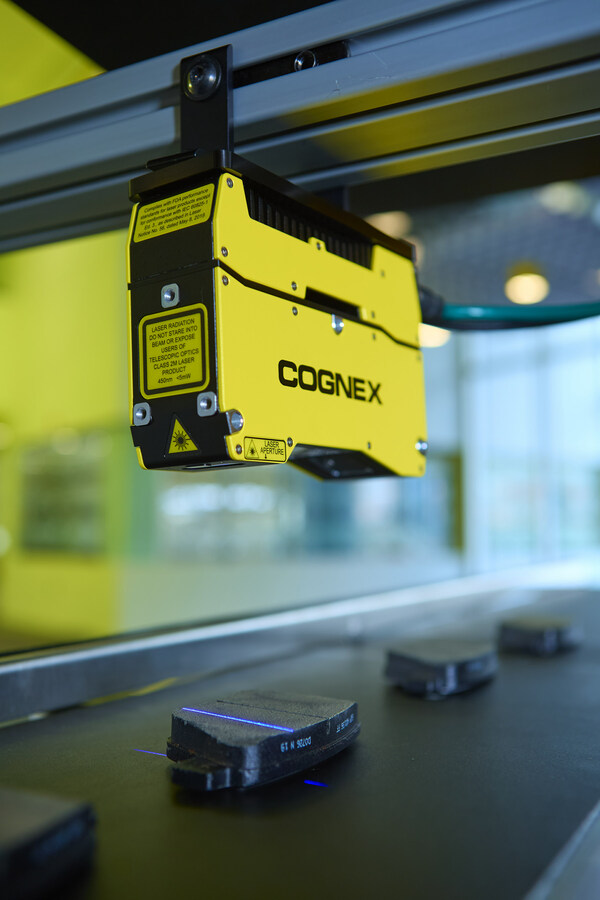

Cognex Steps up Inspection with AI 3D Vision System

Cognex Corporation, the leader in industrial machine vision, has released the In-Sight® L38 3D Vision System. Particularly, it combines AI, 2D, and 3D vision technologies to solve a range of inspection and measurement applications. The system creates unique projection images that combine 3D information into an easy-to-label 2D image for simplified training and reveals features not visible with traditional 2D imaging. Meanwhile, AI tools detect variable or undefined features, while rule-based algorithms provide 3D measurements to deliver reliable inspection results.

“In factory automation fast deployment and reliability are not just desired but essential. In-Sight L38 offers both,” said Carl Gerst, Executive Vice President of Vision and ID Products. “It’s more than a 3D vision system. It’s an AI-powered solution for achieving new levels of quality and performance in automated inspections.”

Mainly, In-Sight L38 greatly simplifies the process of configuring 3D systems thanks to embedded AI technology that uses pre-trained models with domain-specific data. Example-based training replaces complex programming steps, which previously required combining many traditional rule-based tools, to streamline application development. Additionally, the unique AI-powered 3D tools can be set up in minutes, requiring as few as 5 to 10 labeled images to automate a task. With one tool, users can detect challenging defects, gauge variances in three dimensions, and get results in real-world units.

Patented, speckle-free laser optics in the In-Sight L38 minimize visual noise and glare. Accordingly, they capture higher-resolution images than traditional laser displacement sensors. Meanwhile, a high-powered laser delivers fast acquisition rates to support high line speeds. The high-powered laser meets Class 2 safety standards, eliminating the need for expensive enclosures. Also, it offers more light than traditional systems, which lowers exposure requirements and allows for increased line speeds.

The In-Sight L38 Vision System reflects Cognex’s commitment to innovation, setting new standards for 3D inspection and driving advancements in manufacturing automation.

-03 April 2024-