ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Resonac Accelerates Capacity With New ¥15B Investments

Resonac Corporation has decided to increase its capacity to produce materials for high-performance semiconductor chips. Most importantly, the new funding will beef up the company’s muscle to and produce 3.5 to 5 times more of the current level.

Particularly, targeting applications for CPUs for artificial intelligence. Resonac will increase the production of the non-conductive film (NCF) and thermal conductive sheet or the thermal interface material (TIM). Resonac’s customers have already adopted these materials for use in high-performance semiconductor chips.

Accordingly, Resonac plans to shell out ¥15 billion for facilities to produce these materials. The company eyes to commence operations of the expanded facilities this year.

Cutting-Edge Technology

The scale of the market for AI chips in 2027 will likely expand to 2.7 times that in 2022*1. Thus, Resonac will increase its capacity to produce NCF and TIM promptly. Thus, strengthening the company’s predominance over other competitive companies in the market.

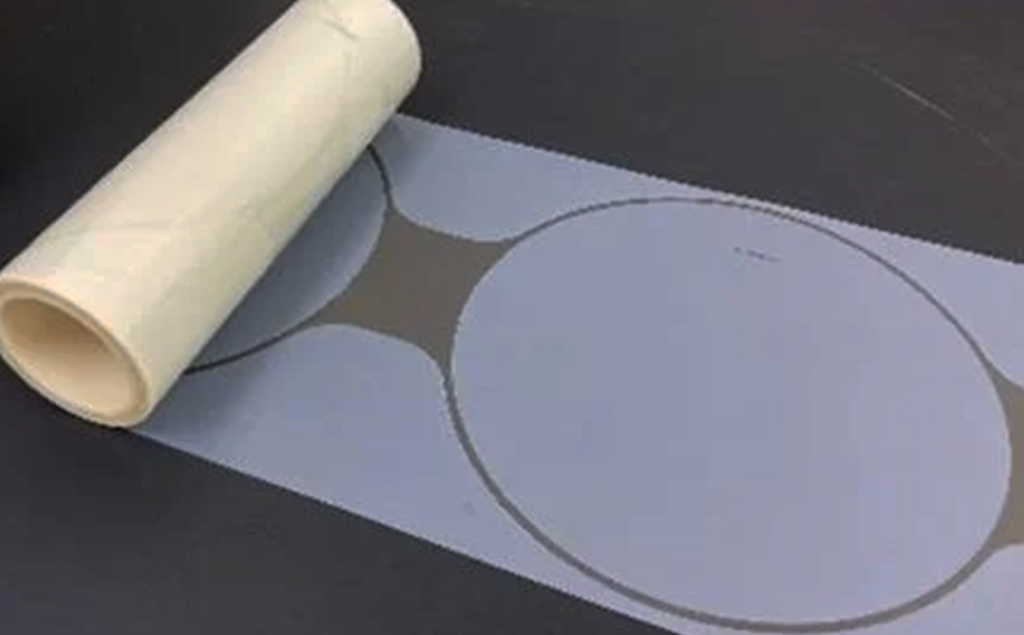

NCF’s usage connects and stacks multilayers of high bandwidth memories (HBM*2), which goes into high-performance semiconductor chips. Essentially, NCF needs to have adhesive strength and realize reliable connection of devices. Moreover, it needs to have precise thickness with a tolerance of less than microns.

Resonac has been producing NCF satisfying quality requirements by making the most of the company’s technologies. Not to mention, its solid experience piled up over many years of development and production of die-bonding film, which is a predecessor of NCF.

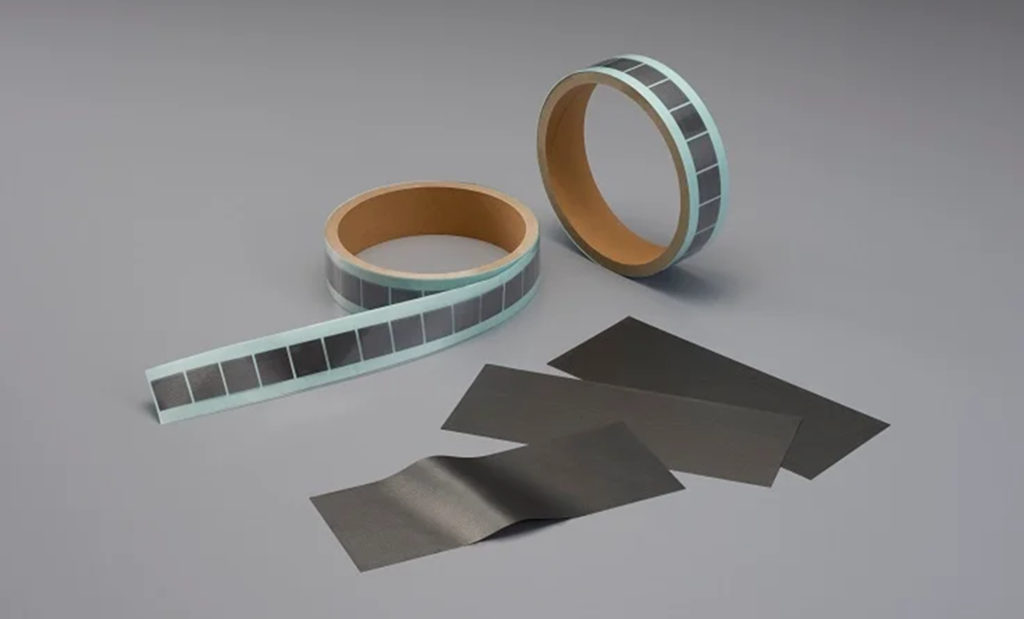

On the other hand, TIM can expedite heat radiation from high-performance semiconductor chips. Hence, TIM needs to have high thermal conductivity to expedite heat radiation from chips generating heat. Moreover, it also needs to endure repeated changes in temperature and the flexibility to adhere closely to fine asperities of chips and radiators*3.

Resonac has been producing TIM satisfying performance requirements by utilizing the company’s original technology to add graphite particles to flexible sheet materials with special placement*4.

Realizing High-Density Mounting

Recently, the evolution of high-performance semiconductor chips in the front-end process of semiconductor manufacturing is reaching the limits and cost performance. Therefore, the 2.xD and 3D semiconductor packaging technologies*5 are becoming key technologies in manufacturing semiconductor chips.

In addition, the utilization of 2.xD and 3D semiconductor packaging technologies is enabling manufacturers to realize high-density mounting of chips in the back-end process. At the same time, improve performance of chips.

Resonac has been promoting R&D on next generation semiconductor packaging materials by utilizing Packaging Solution Center (PSC)*6 and JOINT2*6 consortium. Finaclly, Resonac will continue supporting evolution of high-performance semiconductor chips by promoting co-creation with companies inside and outside Japan. Thus, leading to the development of cutting-edge materials.

Notes:

*1: Source: Gartner (as monetary scale of AI semiconductor market)

*2: High bandwidth memory consists of a laminate of memories and utilizes through silicon via (TSV) technology. furthermore, it has a bandwidth wider than conventional memory chips and can process mass data with high speed.

*3: Radiator is fins of metal attached on a semiconductor package whose chips generate heat.

*4: Resonac can orient graphite particles vertically on the surface of sheet of TIM. Thus, this orientation enables TIM sheet to conduct heat very rapidly.

*5: 2.5D is a technology to place semiconductor chips in parallel on the interposer. Meanwhile, 3D is a technology to laminate chips with TSV (through silicon via).

*6: Packaging Solution Center is a Resonac’s base to promote open innovation on evaluation and packaging technology. It has a full lineup of leading-edge equipment to manufacture semiconductor packages. These include dicing saw to cut wafer, chip-mounting equipment, package sealing equipment, inspection, and evaluation equipment.

On the other hand, JOINT2 is a consortium of 14 semiconductor-related companies established under the leadership of Resonac Corporation and aims to develop next-generation semiconductor packaging technologies and is acting in the Packaging Solution Center.

-4 April 2024-