ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SCREEN Propels Main Cleaning Equipment in China

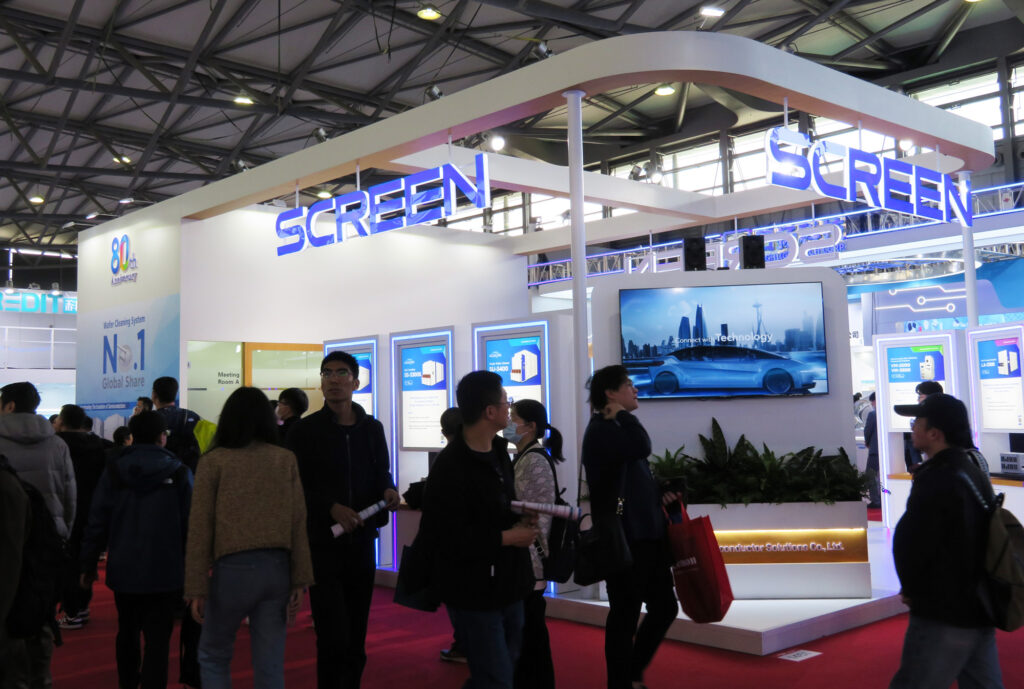

In the recently concluded SEMICON China 2024, SCREEN Semiconductor Solutions Co., Ltd. presented a wide range of products, particularly cleaning equipment, for which the company captures the leading market share.

With the expansion of semiconductor manufacturing in China, the company aims to expand its business by offering cleaning equipment indispensable for semiconductor manufacturing.

This section introduces the initiatives of Japanese companies that exhibited at SEMICON China, a trade fair related to semiconductor manufacturing equipment, materials and components, held in Shanghai, China, from March 20 to 22.

Wide Range of Cleaning Equipment

Specifically, SCREEN Semiconductor presented the SU-3400 single-wafer cleaner, which can handle 300mm wafers, as its main exhibit. Additionally, it highlights high productivity with a maximum of 24 chambers. Meanwhile, the conventional SU-3200 is also a mainstay product in the Chinese market. Primarily, SU-3200 is equipped with 12 chambers. It is compatible with a wide range of chemicals, making it suitable for a wide range of processes.

Tang Yubo, Sales Director, Customer Solution Operations, SCREEN Electronics Shanghai says, “Semiconductor manufacturing in China is booming and demand for cleaning equipment is increasing, and the SU-3400 is beginning to sell well in both memory and logic applications due to its high throughput.”

In addition, the company introduced the DT-3000 coater/developer and the SU-2000 200mm cleaning system, which is attracting increasing demand for use in power semiconductors.

The demand for semiconductor production equipment is rising against the backdrop of the Chinese Government’s policy of semiconductor self-sufficiency. However, concerns about the impact of export restrictions imposed by the United States are still present. Although some functions of some of the company’s products are subject to these restrictions, the company has responded by removing such functions, and there has been no major impact.

“Demand in China is strong due to the domestic production of semiconductors and the global boom in generated AI. We are optimistic about orders in FY2024. We have also started operations at our new plant and have a supply system in place to meet strong demand. We celebrated our 80th anniversary last year and are aiming for further growth,” said Tang.

This is an English translation of a Japanese article originally published in Dempa Shimbun Daily.

-10 April 2024-