ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Sinfonia Exhibits Clean Transport Systems in China Event

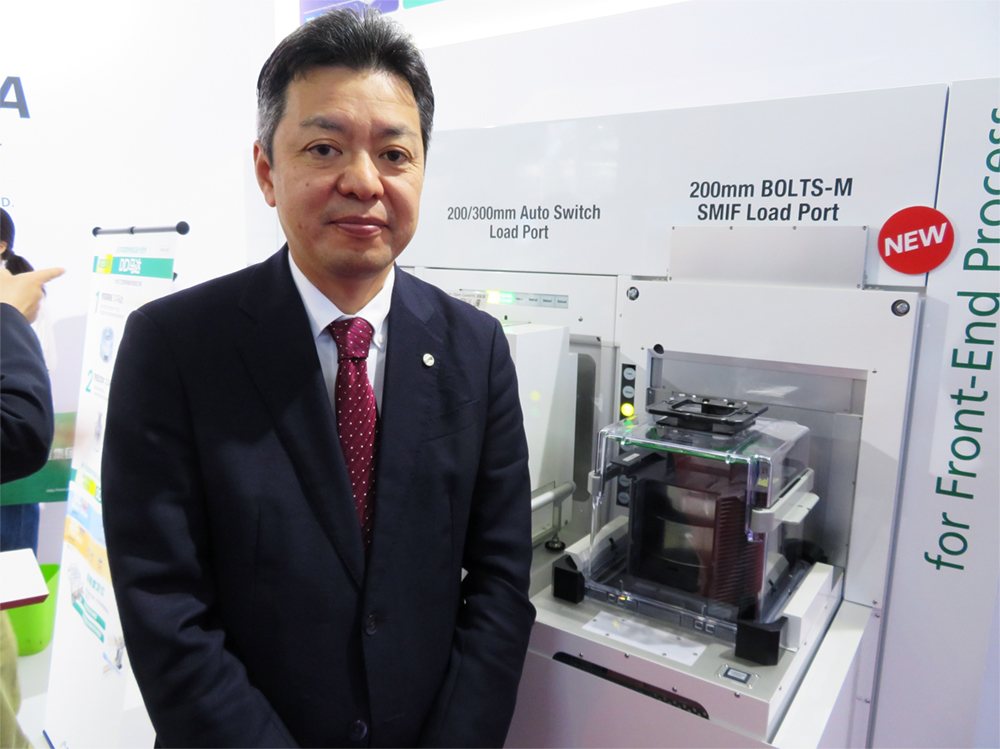

Sinfonia Technology Co., Ltd. exhibited various clean transport systems such as Load Port and Equipment Front End Module (EFEM) at SEMICON China 2024. The company aims to promote its technological strength, which captures a high share of the global market. Also, it wants to increase its visibility in China.

This section introduces the initiatives of Japanese companies that exhibited at SEMICON China, a trade fair related to semiconductor manufacturing equipment, materials and components, held in Shanghai, China, from March 20 to 22.

Meets Demand for Clean Transport Systems

Mainly, load ports are installed at the front of semiconductor manufacturing equipment. They transfer wafers in and out of wafer storage pods (FOUP, SMIF, etc.). Particularly, Sinfonia introduced the SELOP-8 load port, which is compatible with 300mm FOUPs and features an N₂ (nitrogen) filling mechanism.

As processes thread the path of miniaturization, it has become important to take measures to prevent quality effects caused by the ambient atmosphere. Specifically, Sinfonia’s product can maintain a highly clean environment by N₂ purging.

Takashi Ogura, General Manager, Clean Transport System Div. at Sinfonia, says, “The Chinese market shows high interest in a cleaner environment and there are strong inquiries about N₂ purging. Even in the Chinese market, where the use of N₂ purging is currently limited, we expect demand to increase in the future”.

Additionally, the company exhibited the SMIF Load Port for 200mm wafers, which is ideal for power semiconductors. Demand for power semiconductors is growing in China against the backdrop of the increasing popularity of electric vehicles (EVs) and industrial robots. As 150 to 200mm wafers are the mainstream for power devices, inquiries related to this product are increasing rapidly.

Also, the company exhibited the Tape Frame FOUP Load Port for back-end processing. Ogura is stepping up the company’s offerings in anticipation of higher demand. He said, “The adoption of advanced packaging technologies such as 3D integration is progressing. Accordingly, there is a growing demand for manufacturing in a cleaner environment in back-end processes.”

This is an English translation of a Japanese article originally published in Dempa Shimbun Daily.

-10 April 2024-