ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

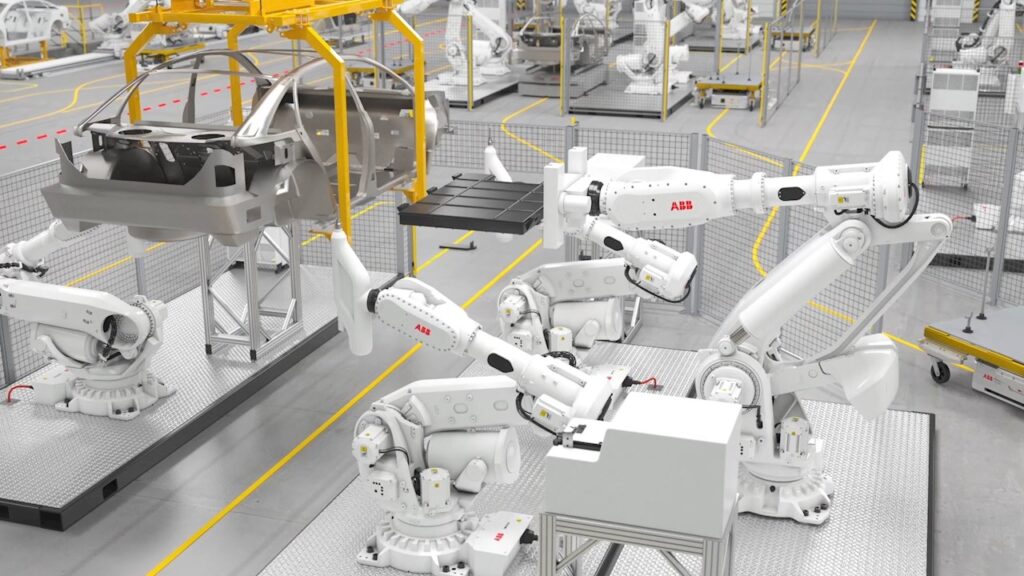

New Models Boost ABB's Industrial Robot Portfolio

ABB Robotics is continuing the expansion of its modular large robot portfolio with the new IRB 7710 and IRB 7720. The new robots, combined with IRB 5710 to 5720 and IRB 6710 to 6740, offer a total of 46 different variants. Overall, they are capable of handling payloads between 70 to 620kg. Thus, it gives customers a new level of flexibility, greater choice and performance in their operations.

“As businesses introduce new technologies and components to meet productivity and sustainability goals, we’ve engineered our modular large robot portfolio to enable them to select the best robots and variants to allow them to efficiently undertake their operations,” said Marc Segura, President – Robotics Division at ABB. “With the most comprehensive portfolio of mechatronic platforms, industrial robots, cobots, and AMRs in the marketplace, the latest robots extend our portfolio even further. Thus, it helps our customers navigate labor shortages and ensure they remain competitive, while operating in a sustainable manner.“

Broad Model Range for Various Fields

ABB’s new IRB 7710 and IRB 7720 robots offer 16 new variants. This way, are ideally suited to support applications across various industries. Operators can choose from a wide range of ABB robots to ensure they have the ideal variant to handle various applications for electric vehicles (EV), hybrid, and traditional car production. These span from press automation, body-in-white, EV battery construction, and final assembly. Also, these robots are perfect for high payload assembly, such as giga casting, high-speed press tending and palletizing, as well as high-accuracy contact applications, such as machining and friction stir welding.

Powered by OmniCoreTM, the new robots achieve class-leading motion control with path accuracy down to 0.6mm, Teven with multiple robots running at high speeds of up to 1600mm/s and moving payloads of up to 620kg. Also, customers can benefit from an up to 25% reduction in cycle times1 further enhancing productivity and quality. In the automotive industry, the all-new IRB 7710 with the latest OmniCore controller will boost the production output of robotic press lines from 12 to 15 strokes per minute to produce 900 parts per hour. Furthermore, in the construction sector, the new robots will support the growth in modular construction, capable of constructing steel building frames and surface finishing, with improvements in speed and quality.

Moreover, the IRB 7710’s energy efficient design in combination with OmniCore’s re-generation technology achieves up to a 30% energy reduction1. Meanwhile, the built-in power pack can relay energy back to the grid.

ABB’s new large robots made their debut at Automate Show, May 6-9, 2024, Chicago, USA.

1 – IRB 7710 compared with its predecessor IRB 7600 running in the same payload of 500kg on the previous controller IRC5.

-08 May 2024-