ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Motor Extends Robonity Series With New Models

Yamaha Motor Co., Ltd.’ Robotics Operations has added new rod type models to the basic model lineup of the Robonity industrial robot series*. Slimmer models with reduced height will also be added to the existing lineup of slider types. These additions to the Robonity Series will expand the lineup to 29 models, offering clients an even greater range of products to choose from.

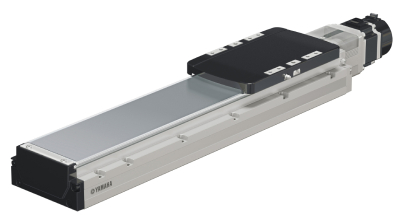

Robonity Series

The Robonity Series includes motorless single-axis actuators. These enable clients to use motors and drivers they are accustomed to and single-axis robots that are bundled with the EP-01 robot positioner. The Series is composed of basic models featuring high rigidity, compact construction, and low cost. It also includes advanced models that highlight high precision, high durability, and cleanroom-ready specifications. These allow clients to select models that best suit their needs.

New Additions

The LBAR motorless single-axis rod type actuator and the ABAR single-axis rod type robot are new additions to the basic model lineup. They have built-in linear guide design that ensures rigidity so that straight-line performance is unaffected even when a radial load is applied. They also have high operational precision with ±0° rod non-rotating accuracy. Their construction contribute to equipment downsizing with a size some 65 percent more compact compared to conventional models. Their design support long strokes up to 800mm.

Meanwhile, the slimmer LBAS12 motorless single-axis actuator and ABAS12 single-axis robot add to the slider type lineup. By reviewing the design and reducing the height greater stability has been achieved. These are ideal when used for the X-axis of Cartesian robots and also contribute to overall downsizing.

Main Features LBAR and ABAR Rod Type Models

High rigidity, compact design, long stroke availability

The LBAR and ABAR rod type feature high-rigidity specification with built-in linear guide. Straight-line performance is not impaired even when a radial load is applied thanks to the one-piece construction with built-in linear guide. Juddering in the direction of rotation is inhibited and tools attached to the tip of the rod achieve ±0° of non-rotating accuracy. It also becomes possible to eliminate the need for an external guide, which saves on the time, effort, and cost involved in installing one.

They feature approximately 65 percent greater compactness than conventional models. Compared to a conventional model (TRANSERVO Series SRD05), a LBAR05 of the same size is some 65 percent narrower in width. This contributes to the downsizing of factory equipment.

They support long strokes at a maximum stroke of 800mm. Compared to a conventional model (TRANSERVO Series SRD05), a LBAR05 of the same size supports approximately twice its stroke capability at 600mm.

Main Features of LBAS12 and ABAS12 Slim Slider Type Models

Slim construction

By completely reviewing the design, external width has been reduced to 120mm and the height lowered to 76mm, thus contributing to the downsizing of facility equipment. The center of gravity is lower thanks to the slimmer construction, making the unit ideal for use as the X-axis of a Cartesian robot. It can also be used across a wide range of situations as it is compatible with both 200W and 400W motors with the same frame width.

*“Robonity” is a coined word combining “robot” and “infinity” together and the name is meant to express the series’ rich array of variations.