ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Sumitomo Bakelite New Polymers Cater to Wide Variety of Uses

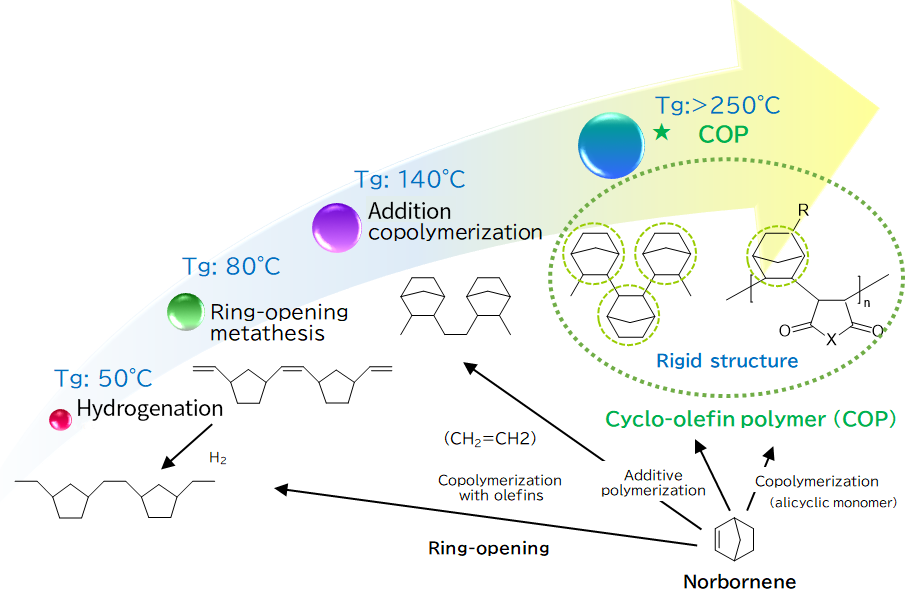

Sumitomo Bakelite Co., Ltd. announced that it has developed an additive polymer (Cyclo-Olefin Polymer; COP) and an additive copolymerized cyclo-olefin polymer (Cyclo-Olefin Copolymer; COC). Accordingly, it has launched as the SUMILITERESIN®PRZ Series.

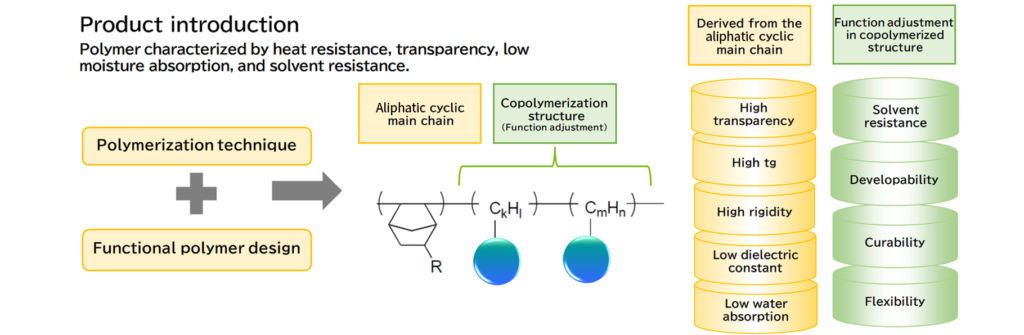

Particularly, this product has features derived from the aliphatic cyclic main chain, such as high transparency, high Tg (glass transition point), high rigidity, low dielectric constant, and low water absorption. Also, by adding functions through polymerization technology, it acquired solvent resistance, developability, curability due to cross-linking groups, and flexibility.

Background

Recently, with the miniaturization and multifunctionalization of information and communication devices, the properties required for polymer materials have diversified year by year. However, general-purpose polymer products are unable to meet the diversifying characteristics required, and more highly functional materials are required.

Cyclo-Olefin Polymers (COP) SUMILITERESIN®PRZ Series

Mainly, cyclo-olefin polymers consist of cyclic hydrocarbons called cyclo-olefin. Also, cyclo-olefins are characterized by their aliphatic cyclic main chain and high thermal and light stability, high transparency, high Tg (glass transition point), high rigidity, low dielectric constant, and low water absorption durability.

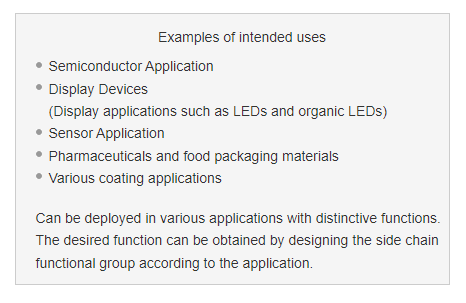

Particularly, they are in a wide range of applications. Among them, food packaging, pharmaceutical packaging, automotive parts, and optical materials. Our company’s cyclo-olefin polymer has properties derived from its aliphatic cyclic main chain and is particularly excellent in heat resistance.

Sumitomo Bakelite’s unique copolymerization technology enables it to add a variety of functions that cannot be satisfied by general-purpose resins.

Additionally, the heat-free light-curing COP can be cured at room temperature, improving the freedom of device design. We are in the process of preparing products that comply with laws and regulations, such as the PFAS-free COP, which is another developed product.

Potential Uses of COP

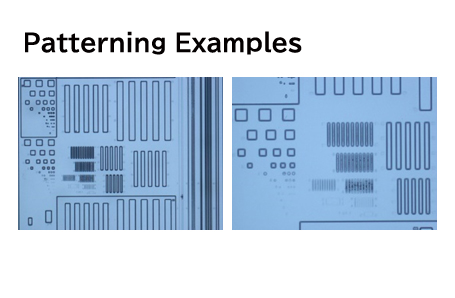

Additionally, the desired function can be obtained by designing the side chain functional group according to the application. For example, by introducing the functional group suitable for the resist application, the application to the positive and negative alkali development patterning material becomes possible.

Example of use according to application

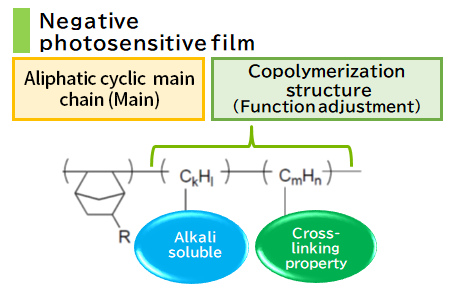

Negative photosensitive film

As a negative photosensitive film, it can be used for photoresist such as semiconductors and displays, and it exhibits effective functions as a negative resist. By attaching alkali-soluble or cross-linkable groups to functional groups, it exhibits functions as a resin for a negative resist.

By irradiating UV through a mask, a photocrosslinkable curing reaction can also be applied. Negative patterns can be formed by alkali development after exposure.

・Photocurable, high transparency, high heat resistance

Application Example

Application Example

Non-Heated Photocuring New COP Low Temperature Process Possible

Particularly, the aliphatic cyclic main chain has excellent thermal stability, so-called high Tg, high pyrolysis point, and various other features such as low water absorption and excellent light transmittance.

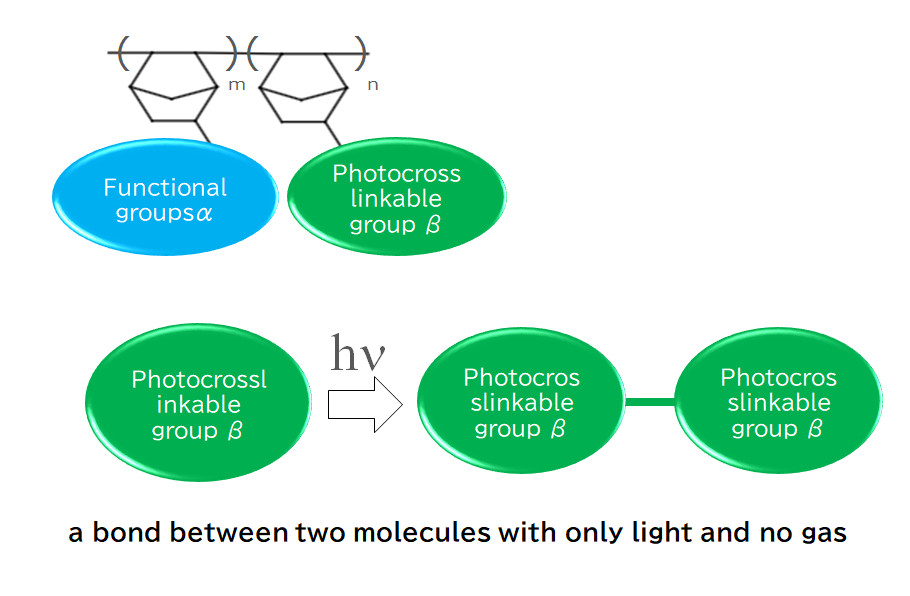

The characteristic of this COP is that it can cure without generating gas only by light. This results in a very clean photo-crosslinked polymer without the need for heat, acids, bases, radicals and other generators.

In addition, it has features of low dielectric loss tangent and low dielectric, low water absorption and high heat resistance, making it possible to support low-temperature curing processes on organic films such as PET films, and can be used in places where conventional processes requiring high temperatures would have been difficult. Patterning is also possible, and solvent development with PGMEA, etc.

- Photocurability, high heat resistance

- Low dielectric, low water absorption

- Resin (heat/acid/base/radical-free) capable of forming crosslinked structure only by introducing photocrosslinkable group β

- Patterning If necessary, solvent development

- It is possible to control the performance by various types of copolymerization and ratios.

Future

The market for COP is expanding year by year, and demand is expected to expand in many fields. Our company expects sales of 5 billion yen/year in the future, and aims to expand further applications.

-03 June 2024-