ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Dymax Boosts System for High Speed and Better Tasks

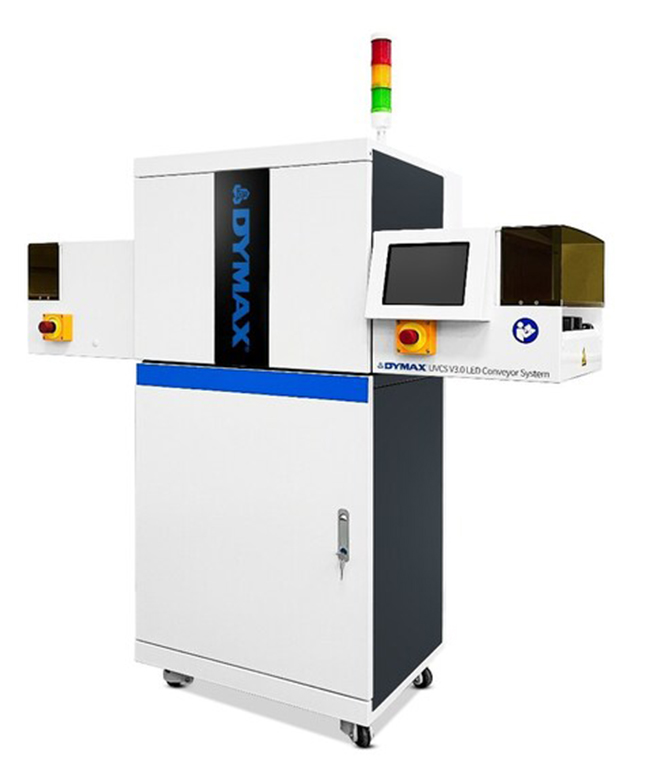

Rapid curing materials and equipment maker Dymax has introduced the UVCS V3.0 LED Conveyor. The latest model is an enhanced version of the renowned and reliable Dymax UVCS conveyor curing systems.

Specifically, it features a modern industrial design and gives focus on user experience. Thus, the conveyor offers a feature-rich, easy-to-use operation with intuitive controls. The revamped system ensures maximum ease of use for operators, enabling faster processing and increased throughput.

Offers Seamless Integration

The unit includes a high-contrast 8-inch touchscreen for managing speed, operation modes, and the LED emitters installed in the conveyor. In addition, the system is fully programmable for belt speed and intensity. It also features a static curing oven mode in addition to high-speed conveying through the conveying tunnel.

Users can use a PLC to activate and operate the system. With a 12-inch-wide belt, automated part sensing, and reversible operation, users can maximize productivity with the UVCS V3.0 LED Conveyor.

Compatible with Dymax’s BlueWave® FX-1250-series LED flood lamps, the UVCS V3.0 LED Conveyor offers seamless integration into existing processes. It provides various emitter mounting options, including a single lamp, line arrays up to 1×3, and side-by-side arrays up to 2×2.

Moreover, the fully enclosed design enhances safety with UV leak protection, and the high-power exhaust system minimizes noise, light, and heat emissions. This system effectively reduces chamber temperature even with high-power curing systems, making it ideal for temperature-sensitive parts.

Furthermore, the stainless-steel components near the belt limit ESD, safeguarding both operators and sensitive parts.

Suits Wide Range of Industries

CE compliant for global use, the UVCS V3.0 LED Conveyor is perfect for a range of curing applications in the medical, consumer electronics, automotive, aerospace and optical, and appliance industries.

Dymax develops innovative rapid and light-curable materials, dispense equipment, and UV/LED light-curing systems. Specifically, the company’s adhesives, coatings, and equipment can work seamlessly with each other. Thus, providing design engineers with tools that dramatically improve manufacturing efficiencies. Among the company’s major markets include aerospace and medical device, consumer, and automotive electronics.

11 June 2024