ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsui Chemicals Ramps up CNT Pellicle for EUV Lithography

Mitsui Chemicals, Inc. has decided to set up production facilities at its Iwakuni-Ohtake Works for carbon nanotube (CNT) pellicles suited for next-generation High NA*1, high-output extreme ultraviolet (EUV) lithography systems. Specifically, EUV lithography will be indispensable in further reducing the size and increasing the production efficiency of semiconductors.

The company targets a production capacity of 5,000 sheets per year. It aims to finish construction of the facilities by December 2025.

What is MITSUI PELLICLE™?

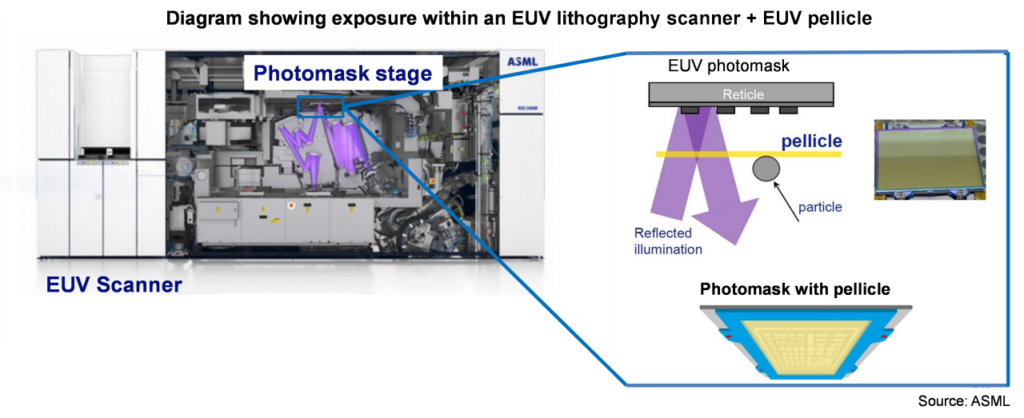

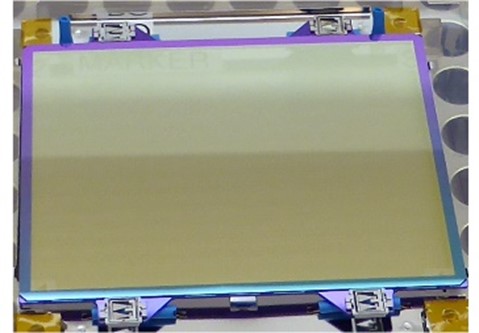

MITSUI PELLICLE™ is a dustproof photomask cover for the photolithography process. Particularly, it sees semiconductor wafers exposed to light to etch circuit patterns. The pellicle is designed with optimal thickness to allow for high transmittance. Also, its membrane material is selected to provide light resistance against each exposure wavelength used. The use of MITSUI PELLICLE™ keeps photomasks clean and helps improve semiconductor productivity.

Mitsui Chemicals started pellicle sales in 1984. Since then, it has continually strived to improve its pellicles and their quality along with the downsizing of semiconductors.

What are EUV Pellicles?

Mainly, ICT is advancing at an increasing pace to solve social issues. In particular, the use of 5G communications, AI, IoT, and big data lead to an increasingly digital society. Meanwhile, the task of processing this data falls on semiconductors. With the requirement for these semiconductors to have high-speed processing capabilities and low power consumption, there is an increasing need for ultrafine circuit widths of 7nm or less. In turn, the industry is seeing rising practical adoption of EUV exposure technology with a wavelength of 13.5nm. Primarily, it is suitable for forming ultrafine circuits.

Mitsui Chemicals has a business licensed by Dutch company ASML Holding N.V. for producing EUV pellicles. In 2021, the company became a global industry leader by beginning commercial production of EUV pellicles at its Iwakuni-Ohtake Works. Accordingly, it helps meet the growing demand for next-generation semiconductors.

What are CNT Pellicles (Next-gen EUV Pellicles)?

Generally, there is particular demand growth for High NA (numerical aperture of 0.55), high-output (600W or above) lithography. This represents the next generation of EUV lithography technology. Also, pellicles made from new materials will be essential to withstand the harsh lithography environments required to make this technology a reality.

Thus, to match these innovations in exposure technology, Mitsui Chemicals has decided to establish mass production facilities. Specifically, this is a step toward commercializing CNT pellicles that have both high EUV transmittance (92% or above) and light resistance for exposure output of over 1kW.

Also, by adding next-gen pellicle products using CNT as the membrane material to its lineup alongside conventional EUV pellicles made with a silicon-based membrane, Mitsui Chemicals hopes to contribute to improved semiconductor performance and productivity.

*1 NA: An abbreviation of “numerical aperture,” a term for a number that quantifies a lens’s ability to concentrate light – including the lens’s brightness, resolution and depth of focus. The larger the number, the more light rays a lens is able to capture, and the better it is able to narrow that light down to a small point.

-11 June 2024-