ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Technology Taps AI for Faster Ceramics Analysis

NGK INSULATORS, LTD., the Tokai National Higher Education and Research System at Nagoya University and Aixtal Corporation have jointly developed an AI-based high-precision analysis method for ceramic products. Along this line, they established a technology that can significantly shorten the time to analyze product characteristics.

NGK will apply this AI technology to its core businesses to shorten the period for product design and evaluation. Also, it will use it to develop new products that contribute to carbon neutrality and the digital society.

AI to Replace Simulation

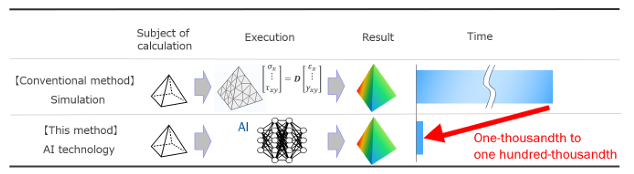

Mainly, this joint development aims to develop a technology that replaces the simulation used to evaluate ceramic products with AI.

Particularly, Nagoya University’s Ujihara Lab took an AI model developed through research on crystal growth methods and improved it for ceramic products. Meanwhile, Aixtal increased the precision of the model and implemented an interface tailored to NGK. For its part, NGK verified the model’s application in product evaluation.

Conventional simulations, while highly precise, require work by a team of experts and take a long time to calculate. With the newly developed AI technology, the same level of precision as simulations can be easily achieved using a laptop computer.

Support Decarbonization

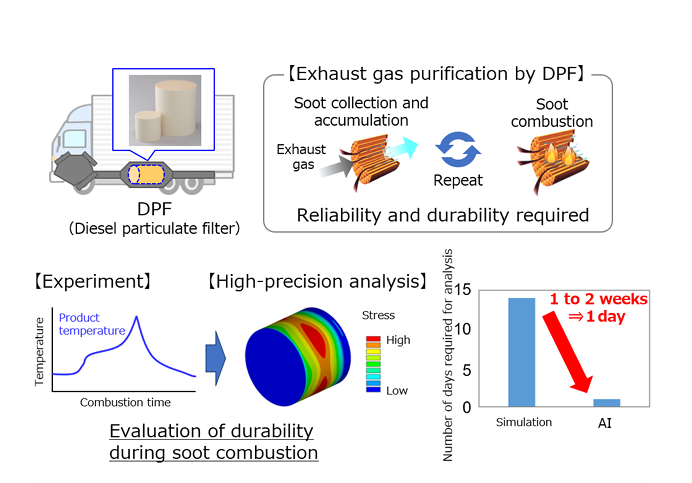

NGK will apply this technology to the evaluation of ceramic products for purifying automotive exhaust gas, one of its core businesses. Because these products are used in harsh environments where they are exposed to automotive exhaust gas and therefore require high reliability and durability, highly precise analyses were conducted repeatedly using both experiments and simulations.

Conventional methods require one to two weeks from the time of obtaining experiment results to the completion of the simulation analysis. However, this AI technology reduces the time to as little as one day. The technology will be incorporated into the design process for mass-produced products during this fiscal year to improve product reliability and shorten design lead times.

Also, this technology can be widely deployed to analyze the characteristics of other ceramic products. NGK aims to use this jointly developed AI technology to accelerate digital transformation (DX) of the design process and quickly create new products that contribute to carbon neutrality and the digital society, as stated in the NGK Group Vision.

Nagoya University strives to become one of the world’s leading research universities and is working to produce world-class intellectual achievements through creative research activities, implement research results in society to resolve social issues, and create, foster, and support startup companies. This joint development project helps promote these efforts.

DX Strategy

To realize a sustainable and prosperous world, as stated in its management philosophy, Aixtal promotes process informatics* as part of its DX strategy to effectively utilize data on prototypes, mass production, and evaluations, and provides solutions to optimize manufacturing processes. Aixtal’s process informatics technology enables rapid analysis of designs, prototypes, and evaluations and helps create added value for ceramic products as well as all other kinds of products.

*Process informatics: A method that uses AI for process design to efficiently and as quickly as possible search for the manufacturing conditions that will produce the desired manufacturing results.

-24 June 2024-