ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Toray Improves X-ray Inspections with New Scintillator Panel

Toray Industries, Inc. has developed a highly durable short-afterglow scintillator panel1 that accelerates non-destructive X-ray inspections 2 and enhances their operational efficiency. It launched this product in Japan and abroad in June 2024.

Generally, companies frequently use non-destructive X-ray inspections to ensure the quality of such critical products. Among them are semiconductors, electronic components, and food products. Primarily, defects or contamination can create major social issues. These include infrastructure disruptions, automobile accidents, and health hazards.

Also, the market for X-ray inspection systems should expand around 10% annually. Among key growth drivers include expanding scope of product inspections, broader inspection targets, and adoption of complete in-line inspections.

Improving Quality of High-Speed X-ray Inspections

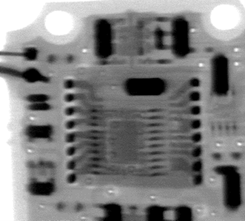

Moving products and cameras swiftly and capturing images at high speeds reduces item inspection times. The downside with scintillator panels using general-purpose terbium-doped gadolinium oxysulfide (GOS) phosphors3 is blurred images (Figure 1), such as transfer direction tails. Meanwhile, praseodymium-doped GOS phosphors5 have short afterglows4 and can sharpen images. However, they are less bright than terbium-doped GOS phosphors.

Also, another challenge is that non-destructive high-speed X-ray inspections are mostly around the clock. Thus, X-ray irradiation erodes scintillator panel brightness, increasing X-ray detector replacement frequency.

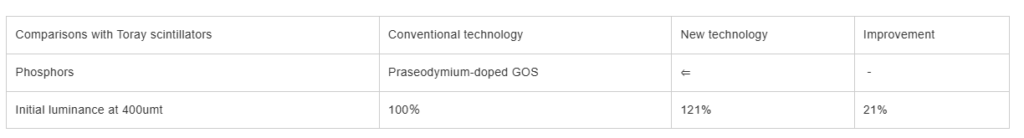

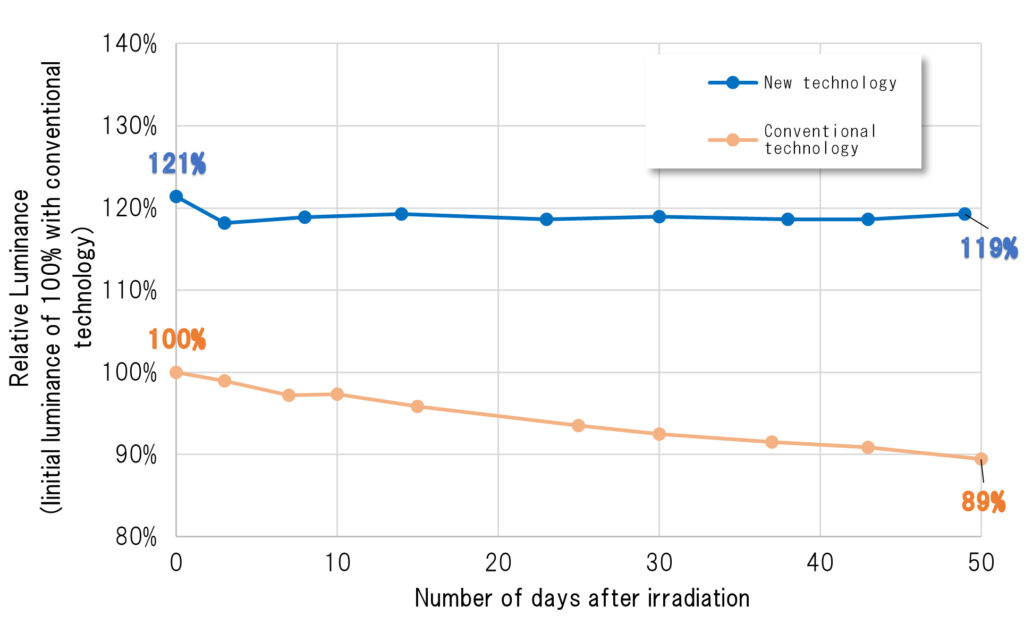

This time, Toray boosted the initial scintillator panel brightness6 by as much as 21% (Table 1). Specifically, it used a highly reflective proprietary base film to achieve this. By identifying and addressing luminance degradation causes, luminance7 after acceleration tests was up to 30% greater than with conventional technologies (Graph 1).

By delivering high brightness and controlling luminance degradation, Toray created a highly durable scintillator panel for fast non-destructive X-ray inspection. Subsequently, the company brought it to market in response to customers finding it valuable for them.

Table 1. Initial luminance comparisons of Toray scintillator panels

- Initial luminance: Measured with Toray equipment at a tube voltage of 70 kilovolts, with no additional filter

- Relative values benchmarked against the conventional technology’s initial luminance of 100%.

- Luminance after acceleration testing: Luminance value after 50 days of X-ray irradiation at 60 kilovolts with a cumulative dose of 1.1 MGy benchmarked against an initial luminance of 100%.

Graph 1. Toray scintillator panel illuminance changes from accelerated testing

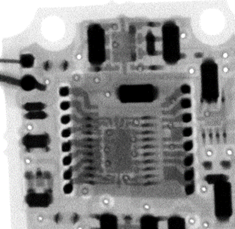

Image captured when measuring electronic components at a transfer speed of 90 m/min.

Toray will maintain its leading position in this area by developing and supplying new X-ray scintillator panels. It will keep innovating materials that contribute to a better society in keeping with its commitment to delivering new value and contributing to social progress.

Notes:

1A short afterglow scintillator panel incorporates a scintillator that emits fluorescence when excited by X-rays. It features shorter time until afterglow emissions reach a certain level after stopping the X-rays.

2Nondestructive X-ray inspections find internal chipping and scratching without disassembling objects by irradiating X-rays and detecting differences in the amounts X-rays transmitted through an object.

3Terbium-doped gadolinium oxysulfide is a phosphor that absorbs X-rays and emits them in the form of visible light and is universally used.

4Afterglow is the luminescence after X-ray irradiation stops. It is the decay time, which is how long it takes for luminance to reach 1/e (Napier number) after X-ray irradiation stops. The afterglow (afterglow luminance divided by initial luminance) after a certain time is used as an indicator.

5Praseodymium-doped gadolinium oxysulfide is a phosphor that absorbs X-rays and emits light at a different wavelength, resulting in a shorter afterglow than terbium-doped gadolinium oxysulfide.

6Initial brightness results from using Toray equipment to measure in-house products 400 micrometers thick at a tube voltage of 70 kilovolts, with no additional filter. Relative values are benchmarked against the conventional technology’s initial luminance of 100%.

7After measuring initial luminance with in-house equipment, Toray obtained luminance values 50 days after irradiation with a cumulative 1.1 MGy of X-rays at 60 kilovolts. It shows the difference between the initial luminance of 100% and relative value.

-08 July 2024-