ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FUJI Launches New Atmospheric Pressure Plasma Unit

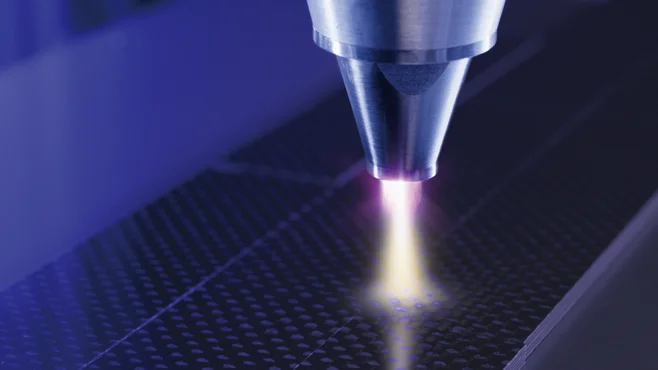

FUJI Corporation has developed an atmospheric pressure plasma unit ATOM that can generate plasma with air. Unlike conventional models, ATOM does not require a nitrogen generator. Thus, it can be used in a wide range of industries by reducing equipment costs, which was an issue for introduction.

FUJI will begin to accept orders for the new atmospheric pressure plasma unit this month.

Significant cost savings, environment-friendly Air model

Development Background

To ensure the function and quality of bonding using adhesives, surface treatment technology, including cleaning, for adherends is very important as a pretreatment for bonding. FUJI has contributed to the improvement of the bonding quality of many customers through the development and sale of surface modification equipment using atmospheric pressure plasma units.

In recent years, as exemplified by the weight reduction of automobiles, multi-materials have been used in the right place for different materials. Moreover, the number of places where different materials are joined with adhesives is increasing. Along with this, the demand for surface treatments that improve the quality of the bond is also growing rapidly.

Also, in the surface treatment process, many customers use chemical solvents and chemicals to clean the surface to be adhered to the surface. However, due to the growing environmental awareness, the method with a lower environmental impact has been attracting attention.

On the other hand, plasma equipment exhibits a high cleaning effect by reducing the use of chemicals. However, it faces limited adoption due to installation costs and maintenance problems.

Therefore, FUJI has developed the atmospheric pressure plasma unit “ATOM” with low environmental impact and reduced equipment costs.

Product Features

In general, air-based plasma units tend to have a high temperature at the generation point and reduce their durability. In response to this problem, ATOM has improved durability by reviewing the structure of the plasma generation section. As a result, it has been possible to significantly reduce maintenance costs. In addition, compared to conventional models that use nitrogen to generate plasma, it is an environmentally friendly plasma unit that consumes less power.

(1) Easy to install and operate: All you need is compressed air and a 200V power supply

(2) Ultra-high-speed processing: The world’s fastest level of air-based plasma; Achieves 800 mm/s

(3) Maintenance-free: There is no need to clean the nozzle, and replacement of consumables only once or twice a year. (*Under FUJI specified conditions)

(For details, please refer to the following URL) Tough Plasma site: https://plasmaknow.fuji.co.jp/products/atom.html

Case Studies

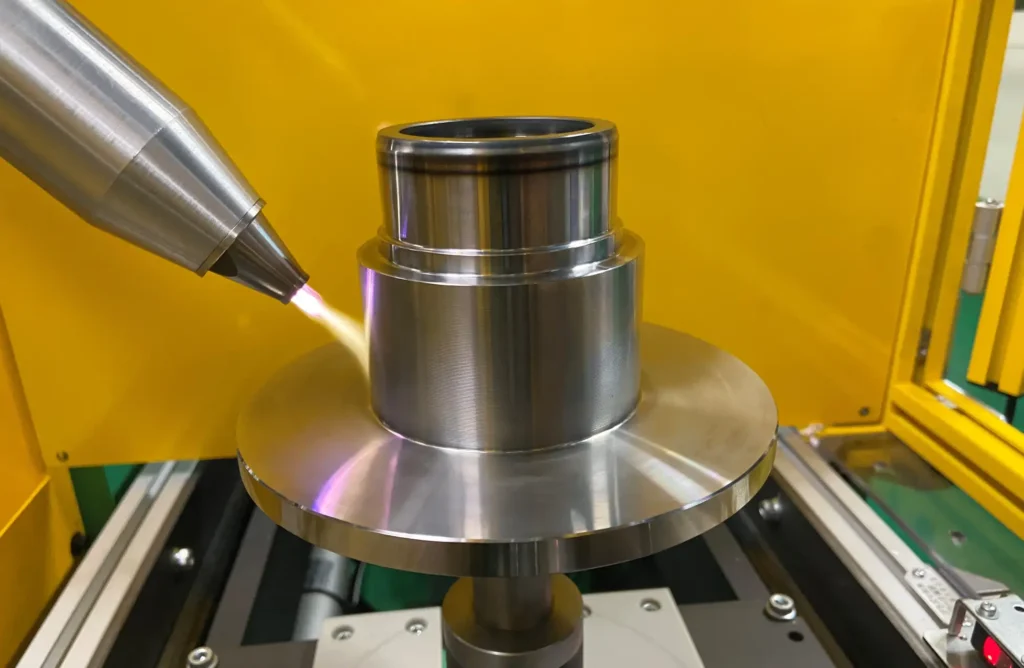

Pre-adhesive treatment at the Yokohama Plant of Japan Shaft Co., Ltd.

The adhesion between the main body (metal) and the resin cover in the metal bat production process has been improved with the introduction of ATOM. In addition, process automation has been realized by replacing manual degreasing cleaning with plasma cleaning using robots.

Pre-painting treatment at Univance Co., Ltd.’s Head Office Factory in Kosai City, Shizuoka Prefecture

The adhesion of the coating film in the coating process of automobile transfer parts has been improved with the introduction of ATOM. In addition, by changing the cleaning solution from strong alkali to weak alkali, achieving an environmentally friendly manufacturing.

Future Development

To meet the ever-expanding demand for plasma bonding using adhesives, FUJI will strive to contribute to environmentally friendly manufacturing by aiming to popularize atmospheric pressure plasma units that can be used by all customers who have issues with adhesion and painting.

This is an online translation of a press release in Japanese with slight editing made by Dempa.

-08 July 2024-