ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SICK's New Tech Makes Big Leap in 3D Applications

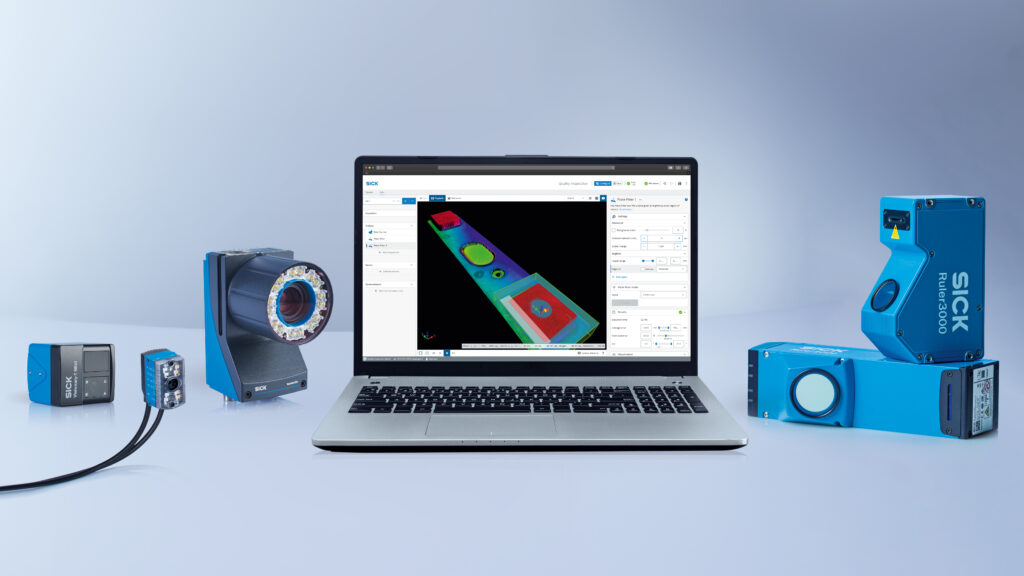

With the new Nova support for Ruler3000, SICK is now making fast, precise high-end 3D vision applications. Accordingly, users can now deploy custom applications within minutes.

Moreover, it can inspect minute details at remarkable speeds. This advancement promises significant enhancements in production efficiency and yield.

Moreover, with Nova now supporting Ruler3000, the speed, accuracy, and possible range of applications of SICK Nova have taken another large step forward.

SICK Nova software, working together with the SIM2x00 and the Ruler3000 camera, now brings its well-established and highly valued user-friendly web interface to high-speed 3D applications. Thanks to the power of AI, this user-friendly setup enables even those companies lacking programming expertise to swiftly configure and manage complex applications.

Configurable 2D and 3D machine vision solutions

Well-known across a wide variety of industries, SICK Nova is the foundation software for configurable machine vision solutions and quality control applications. Specifically, the software already offers a large selection of tools, making it a highly versatile software. What makes it truly stand out is the combination of AI functionality and a straightforward user interface. With these aspects, even users with no programming experience can quickly develop solutions for specific applications.

Ruler3000, the perfect vision partner

SICK’s Ruler3000’s integrated streaming camera delivers reliable scans at rapid production speeds. Moreover, SICK’s highly sensitive CMOS sensor and innovative rapid on-chip calculation (ROCC) technology power the machine.

Processing up to 15.4Gbit/s, it can generate up to 7000 full-frame 3D profiles per second. This allows it to accurately capture the true 3D shape of objects regardless of color or contrast.

Additionally, it simultaneously captures greyscale and scattered light measurements, which results in more precise image processing and measurement.

The Ruler3000 is ideal across many industries and applications. Its high light sensitivity enables accurate inspection of even very dark or highly reflective materials.

Meanwhile, its high dynamic range (HDR) function allows components with widely differing light remissions, such as tires and shiny metal assemblies, to be captured successfully in a single scan.

SIM2x00 Nova Sensor Integration Machine, the ideal interface

The SIM2x00 Sensor Integration Machine is the connector between SICK Nova software and any one of a wide range of 2D and 3D streaming cameras. The specificity of its design allows it to process all the relevant data quickly and efficiently.

A wealth of possibilities

Meanwhile, the quality and flexibility of Nova for Ruler3000 make it the ideal system for a surprising range of applications. This includes such things as the quality control of baked goods and confectionary where properties such as shape and dimensions can be checked at high speed, ensuring their quality even if there is no color contrast.

In addition, the system is equally good for much smaller, more precise tasks such as checking the position the metal contacts around a semiconductor chip during electronic device assembly or the quality of welded joints.

Highly accurate 3D inspection enhances quality and accelerates processes across industries. Furthermore, the Nova for Ruler3000, joins SICK’s suite of products to address these needs and drive down production costs.

23 July 2024