ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ABB to Offer Better Energy Savings With New Solution

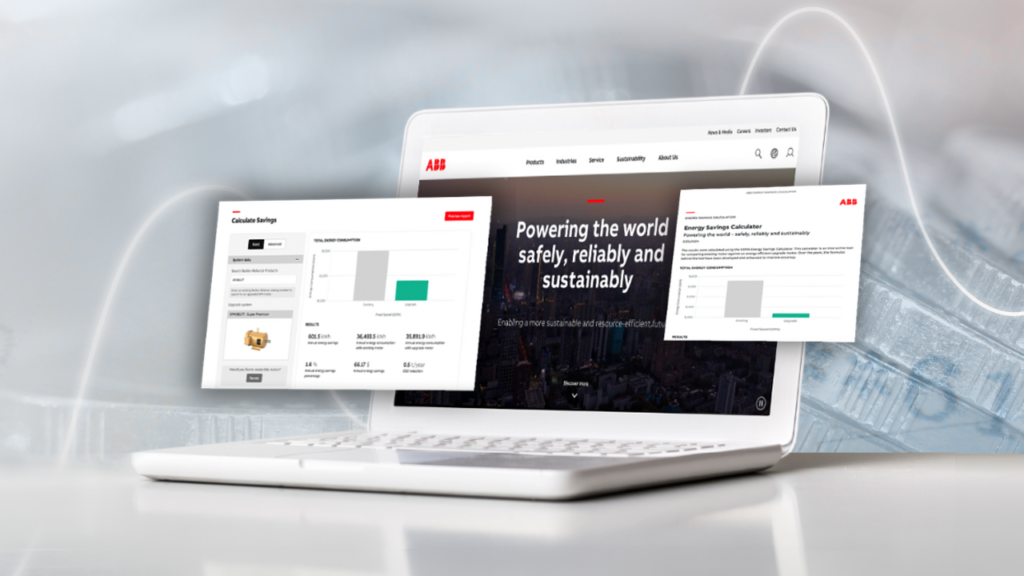

ABB announced it has developed its NEMA motors Energy Savings Calculator. Specifically, this will help motor operators better understand the financial and environmental benefits of upgrading current and end-of-life industrial electric motors.

Accordingly, 45 percent of the world’s electricity powers electric motors in buildings and industrial applications.1 Thus, by 2030, the cost is likely to reach US$900 billion annually.2

Lowering CO₂ emissions and increasing energy efficiency is critical. However, it is also essential for ensuring stable and productive industry operations, lowering operating costs and total costs of ownership.

Offers Advanced Comparison, Options

The Energy Savings Calculator is an online tool. Particularly, it allows users to compare the electrical energy usage, costs, and CO2 production of a motor currently in operation with that of a newnABB Baldor-Reliance® SP4™ NEMA Super Premium® efficiency motor.

The tool has two modes: basic and advanced. The basic function allows users to search existing ABB Baldor-Reliance motors by catalog number. On the other hand, the advanced option has fields for motor parameters such as power, efficiency class, speed and enclosure type. This allows for comparisons with any existing motor.

Annual savings in kilowatt hours, energy percentages and U.S. dollars are available. Furthermore, it can also generate energy consumption comparisons between the new and existing motor and annual CO2 reduction. A digital report with data and graphics can be exported in both the basic and advanced functions.

Meanwhile, the Phase 2 of the Energy Efficiency Calculator, scheduled to launch later this year, will add variable speed motor calculations. In addition, it will have input capabilities for multiple motors and additional enhancements to the current options.

Significant Rewards in Energy Savings, Sustainability

ABB Baldor-Reliance SP4 motors are highly efficient, running cooler, reducing heat-based energy losses, and extending bearing and other component life. Reducing energy losses also leads to lower electrical energy consumption, which lowers operating costs and the total cost of ownership. They meet current U.S. Department of Energy efficiency standards as well as anticipated Medium Electric Motor (MEM) regulations, which take effect on June 1, 2027, in the United States.

“With so much of the world’s electricity being used to power industrial electric motors, investing now in high-efficiency motors will yield immediate, significant rewards in terms of energy savings and sustainability,” said Ben Hinds, vice president of product marketing and management for ABB’s NEMA Motors Division.

It has been estimated that, if all of the more than 300 million industrial electric motor-driven systems currently in operation were replaced with optimized, high-efficiency equipment, global electricity consumption could be reduced by as much as 10 percent.3Thus, the benefits of greater energy efficiency go well beyond the fight against climate change.

They contribute broadly to environmental conservation, cleaner air and water, better public health, energy independence and stronger economic growth and development.

Notes:

1] ABB, 2021. Achieving the Paris Agreement – The vital role of high-efficiency motors and drives in reducing energy consumption

2] ETC, 2021. Making Clean Electrification Possible: 30 Years to Electrify the Global Economy

3] Waide, P. and C.U. Brunner, 2011. Energy-Efficiency Policy Opportunities for Electric Motor-Driven Systems, International Energy Agency working paper

14 August 2024