ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Cloud-Based CAE Solution Predicts Polymer Behavior

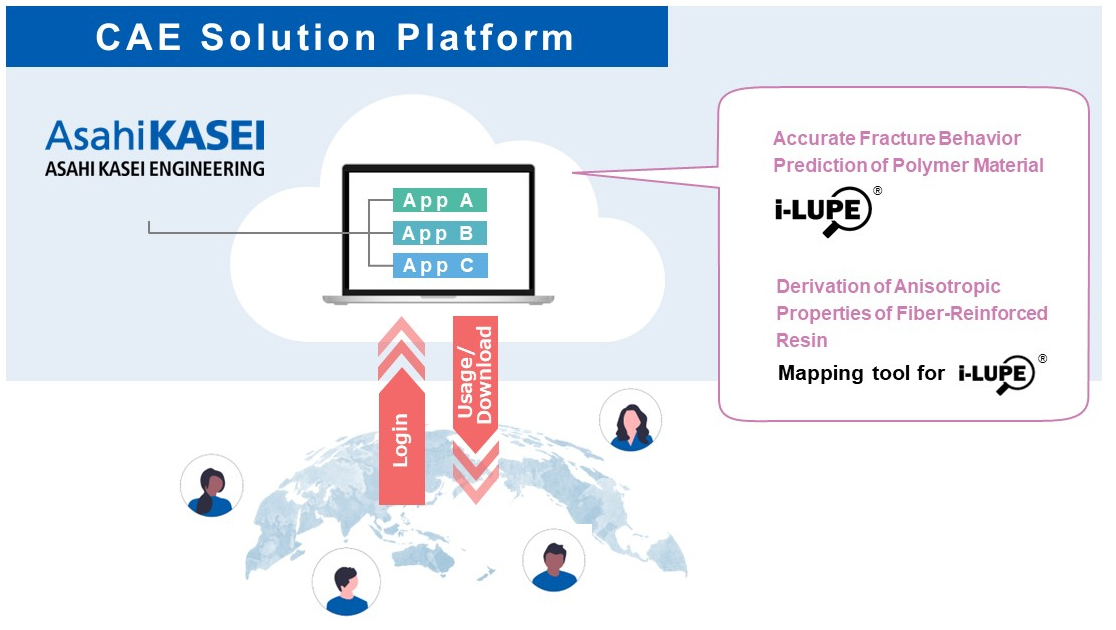

Asahi Kasei Engineering Corp. (AEC) has launched a cloud-based computer-aided engineering (CAE) solution platform that offers highly precise apps to predict crash and impact behavior of polymers.

Generally, the adoption of polymer materials in automobiles and other products has been increasing. Thus, precise simulation of material behavior will contribute to enhanced product design. Also, it will significantly reduce costs and time for material and application development. In recent years, the use of cloud-based high-performance computing (HPC) has been increasing throughout various industries. As a result, the on-demand use of CAE software installed in cloud HPC as software-as-a-service is also becoming more common in the material development process.

As a manufacturer of technical polymers, Asahi Kasei has provided comprehensive, high-precision support for its customers’ product design and development through CAE technical service focused on engineering plastics. Leveraging this expertise, AEC, a subsidiary of Asahi Kasei, further extends its CAE-related service by launching the cloud-based “CAE Solution Platform.” Through this, it offers various apps that can be easily downloaded and used by customers worldwide.

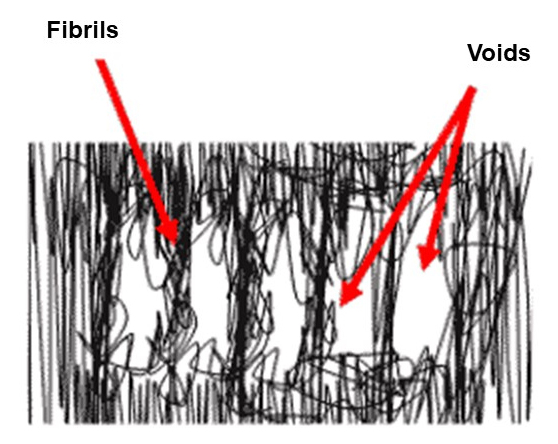

Highly Accurate Fracture Prediction Application

Mainly, the apps offered on the platform include the downloadable and highly accurate polymer material fracture prediction model “i-LUPE.” Microscopically, the structure of amorphous polymer materials contains intricately entangledmolecular chains. When an impact or other force is applied to this material causing significant deformation, the molecular chains are stretched. Thus, it results in the formation of voids and fibrils (bundles of molecular chains). When these so-called crazes grow, the polymer material fractures.

By focusing on crazes, “i-LUPE” accurately predicts and reproduces possible fractures in the polymer.

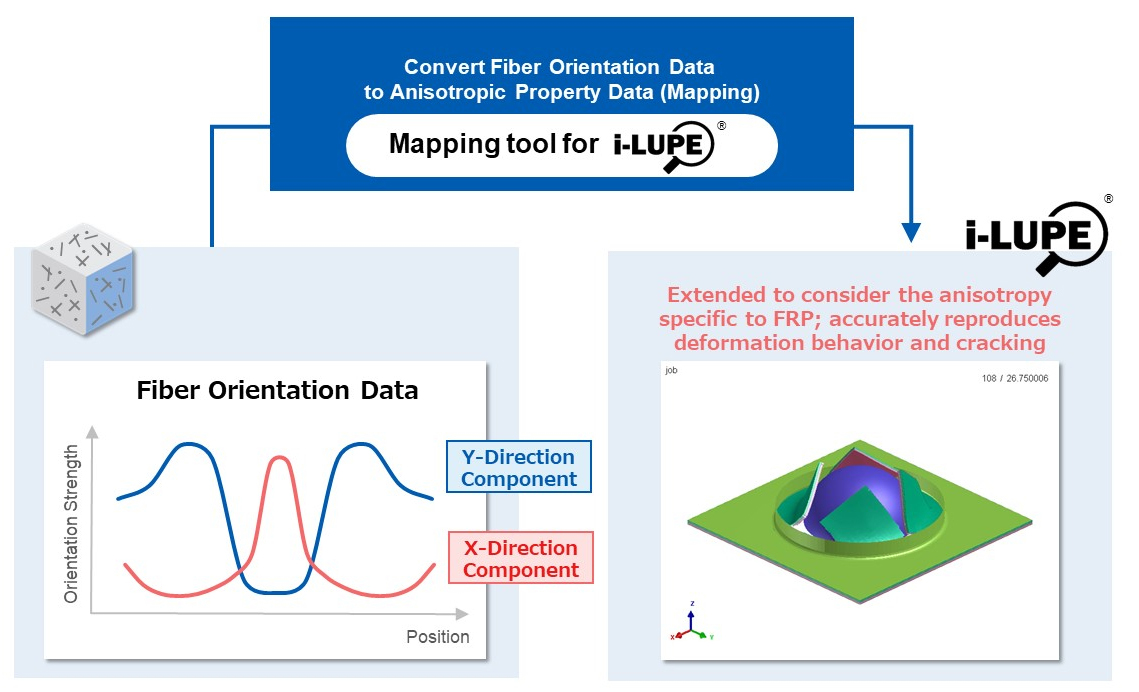

Supporting Mapping Tool

As a supporting app to “i-LUPE,” the CAE solution platform offers an on-demand mapping tool specifically focused on anisotropic materials such as fiber-reinforced resins. Particularly, this tool converts fiber orientation data into “i-LUPE” material property lists. In turn, these are used as reference for selecting the optimal material for specific applications. Thus, it enables an accurate visual representation of deformation behavior of fiber-reinforced resins.

-06 September 2024-